Automatic wire clamp pressing device and wire clamp pressing method

An automatic and equipment technology, applied in the field of automation, can solve the problems of high purchase cost, achieve the effect of improving the pressing precision and quality of pressing, and improving the degree of automation and pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

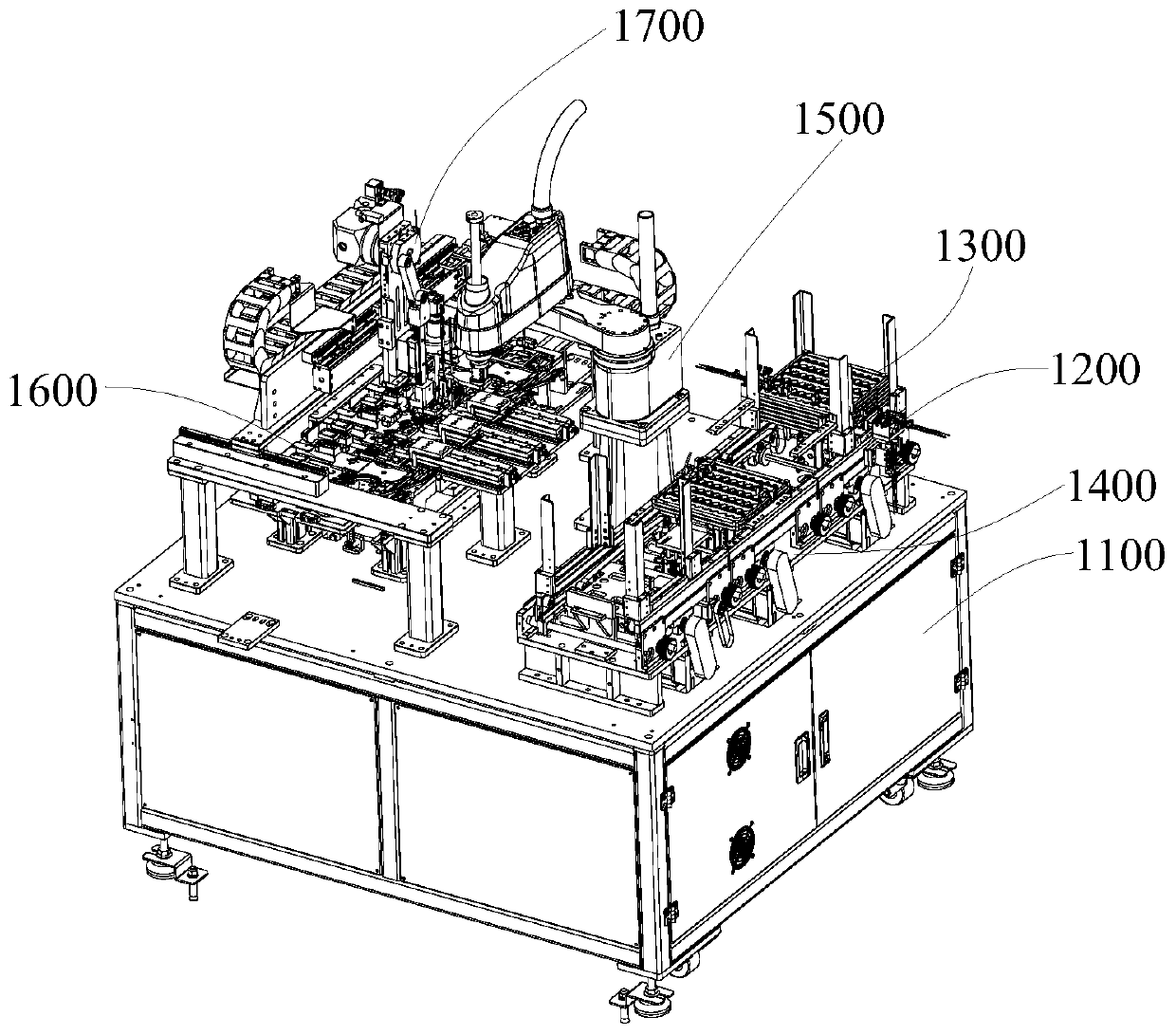

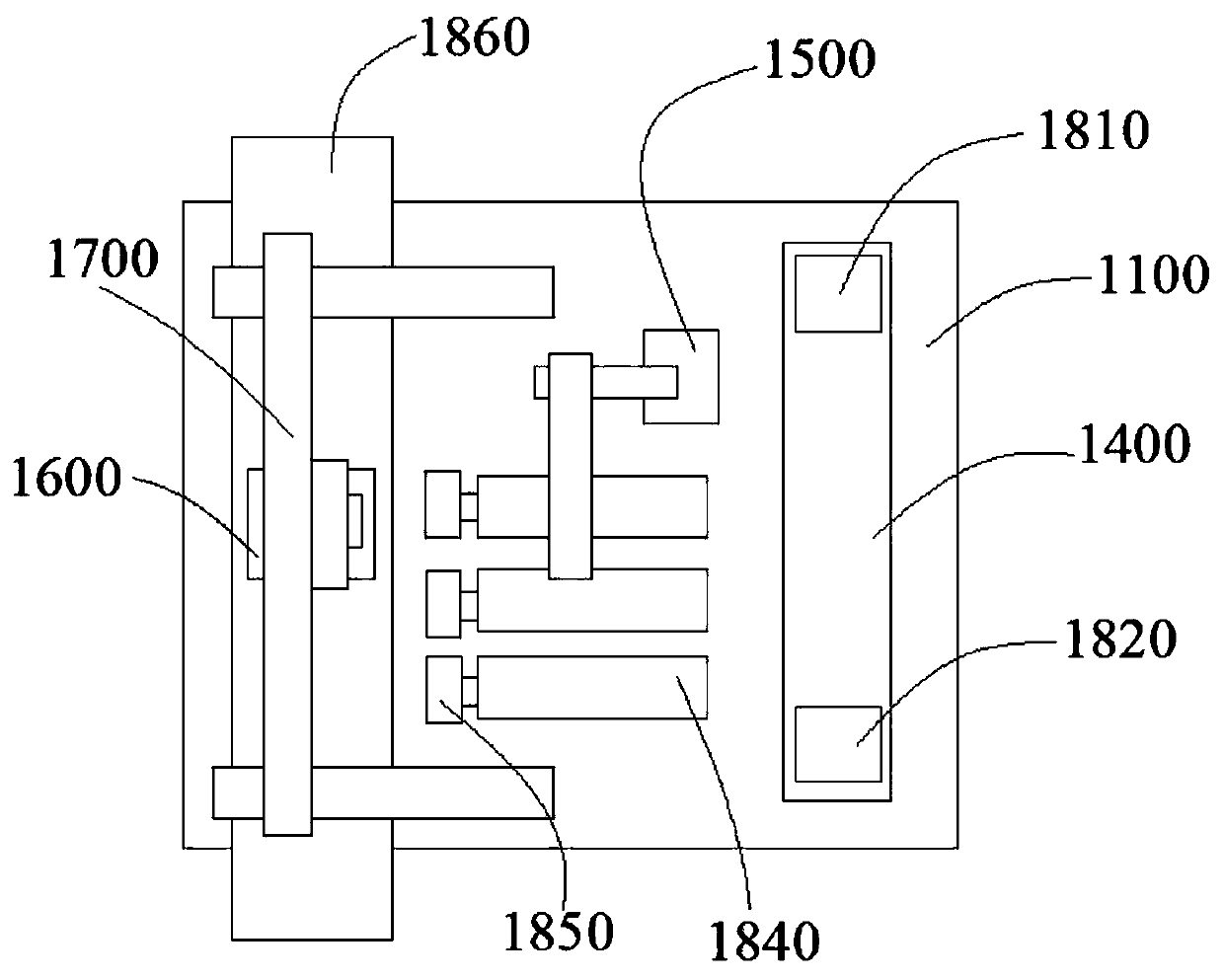

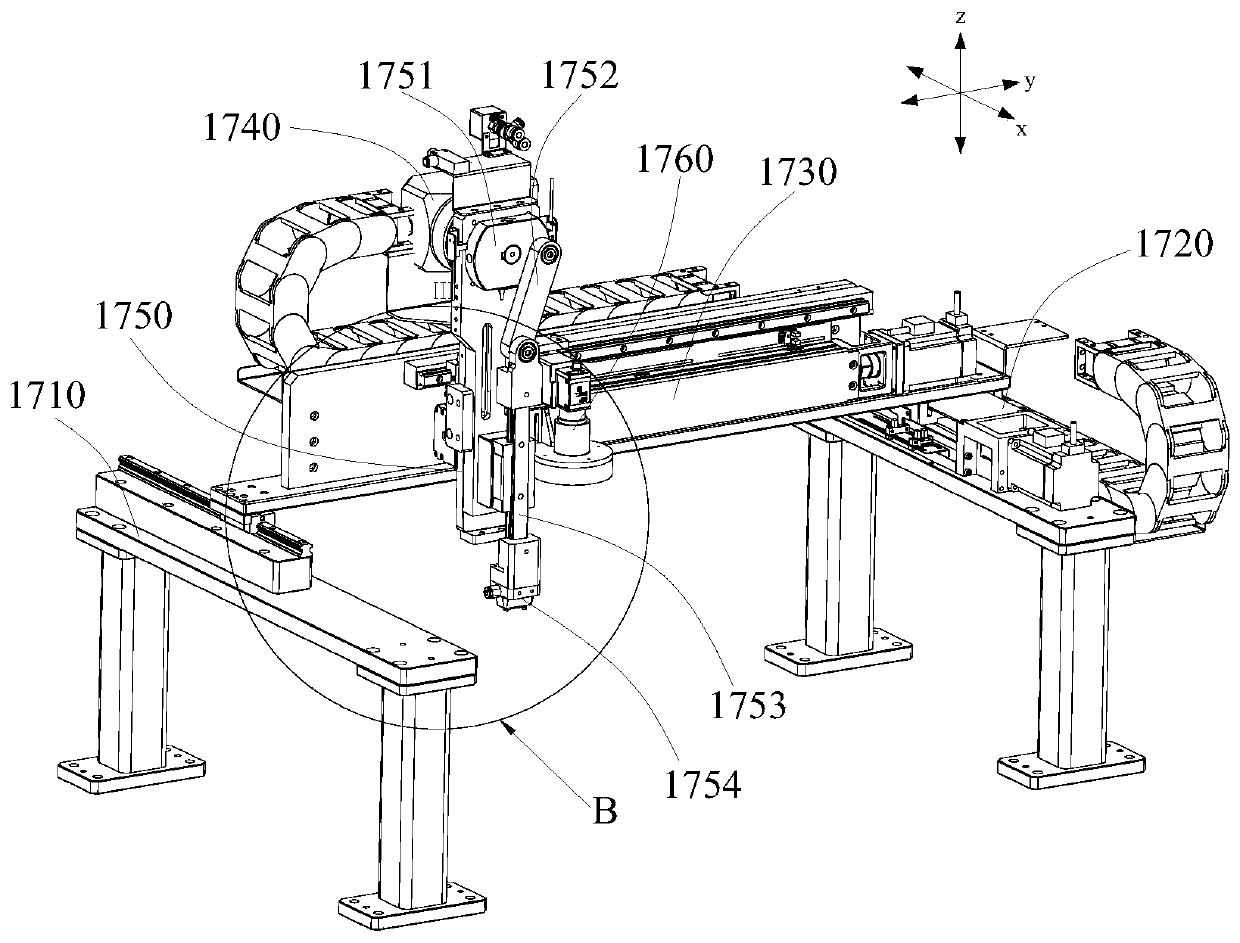

[0053] Such as Figure 1-Figure 4 As shown, an automatic wire crimping clamp equipment includes a crimping device 1700, and the crimping device 1700 includes a plane moving mechanism, a crimping mechanism 1750 and a visual guidance mechanism 1760 arranged on the plane moving mechanism; the crimping mechanism The lower end of 1750 is provided with an upper wire clamp 1871 acquisition mechanism and can press the obtained upper wire clamp 1871 on the lower wire clamp 1872. The visual guidance mechanism 1760 can take pictures of the upper wire clamp 1871, and the plane moving mechanism drives the press according to the photographing results The bonding mechanism 1750 moves to the pressing station. In this embodiment, after the acquisition mechanism acquires the upper wire clamp 1871, the visual guidance mechanism 1760 takes a picture of the upper wire clamp 1871 to obtain guidance information such as the position, shape, and size of the upper wire clamp 1871, and the planar moveme...

Embodiment 2

[0085] A kind of crimping clip method, comprises the following steps:

[0086] S1. The pressing device 1700 acquires the upper wire clamp 1871 and obtains the guide information of the upper wire clamp 1871 by taking pictures;

[0087] S2. Guide the crimping device 1700 to move to a corresponding position according to the guiding information to complete the crimping of the wire clips.

[0088] The upper wire clip 1871 is photographed before wire clip pressing to obtain guidance information. According to the guidance information, the pressing device 1700 can be accurately guided to move to the corresponding position for wire clip pressing, which improves the pressing accuracy and pressing quality.

[0089] It should be noted that the guide information includes parameters such as the position, shape, and size of the upper wire clamp 1871 . A wire crimping method in this embodiment can be realized by using the device in Embodiment 1.

[0090] Further, the step S1 includes:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com