Error-preventing cartridge clip-type feeding bearing automatic press fitting mechanism and method

A clip-type, pressing mechanism technology, applied in the field of pressing mechanism, can solve the problems of high input cost and maintenance cost, complex mechanism of vibrating material system, large occupied area, etc., and achieve small occupied area, simple and compact structure , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

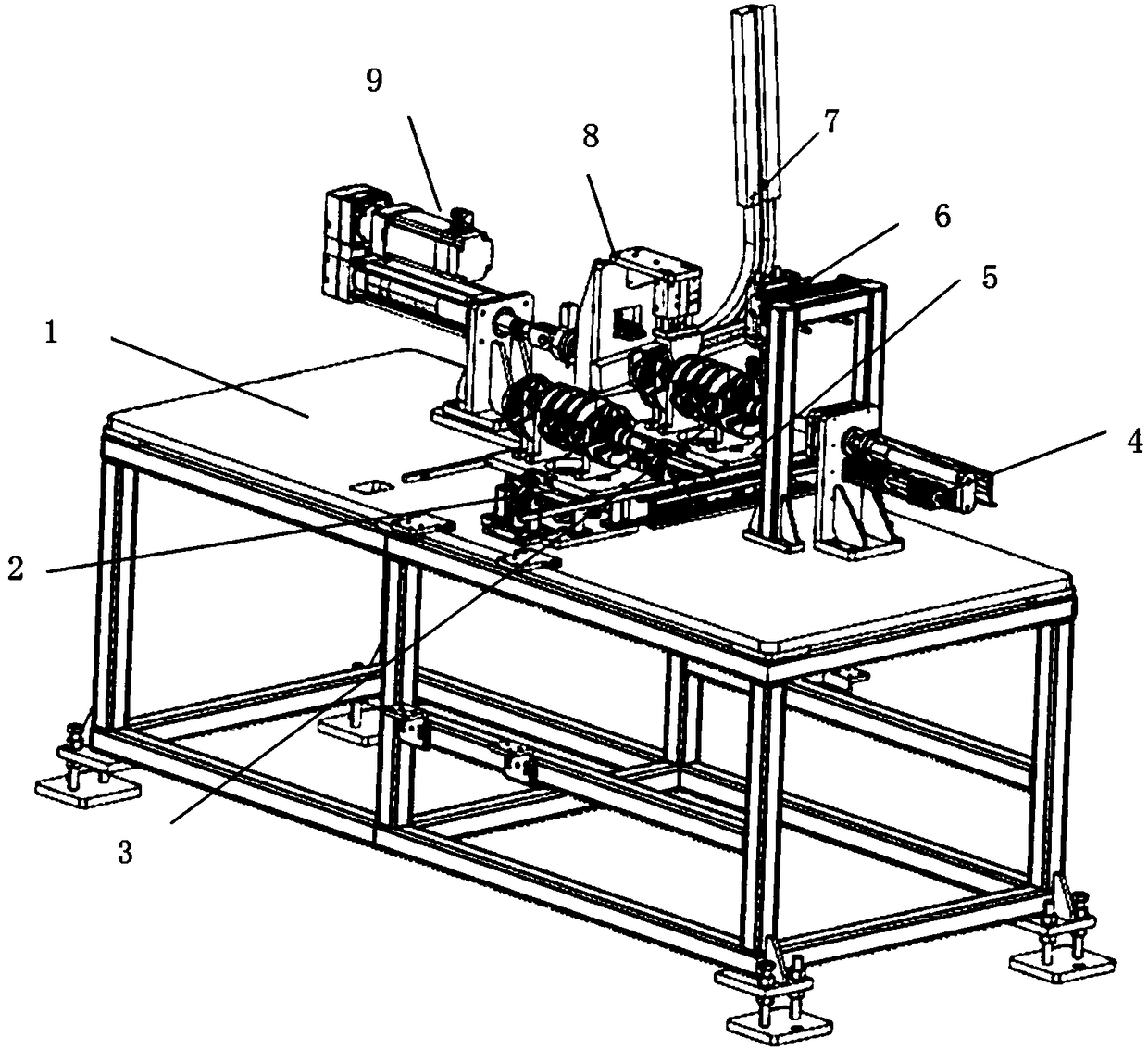

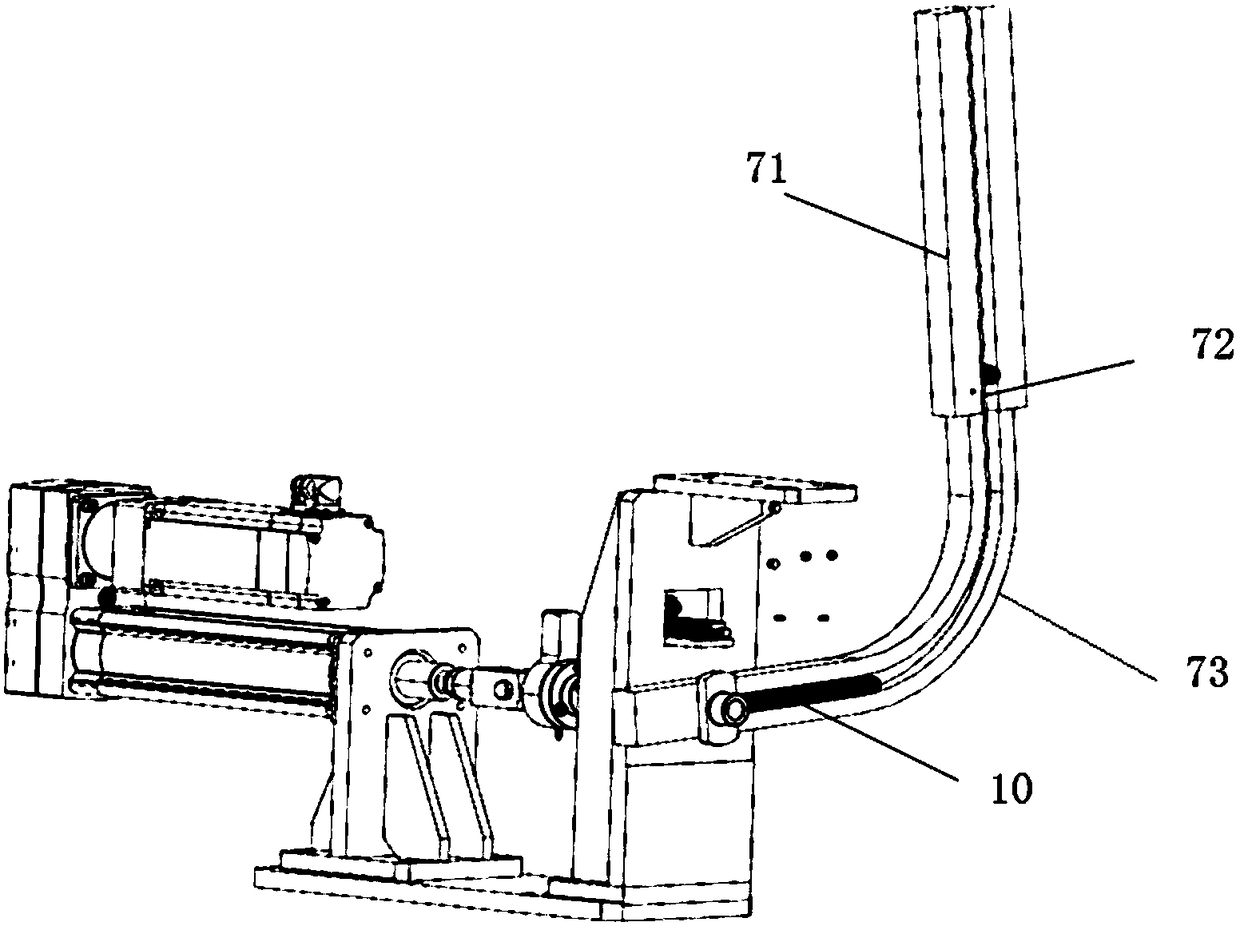

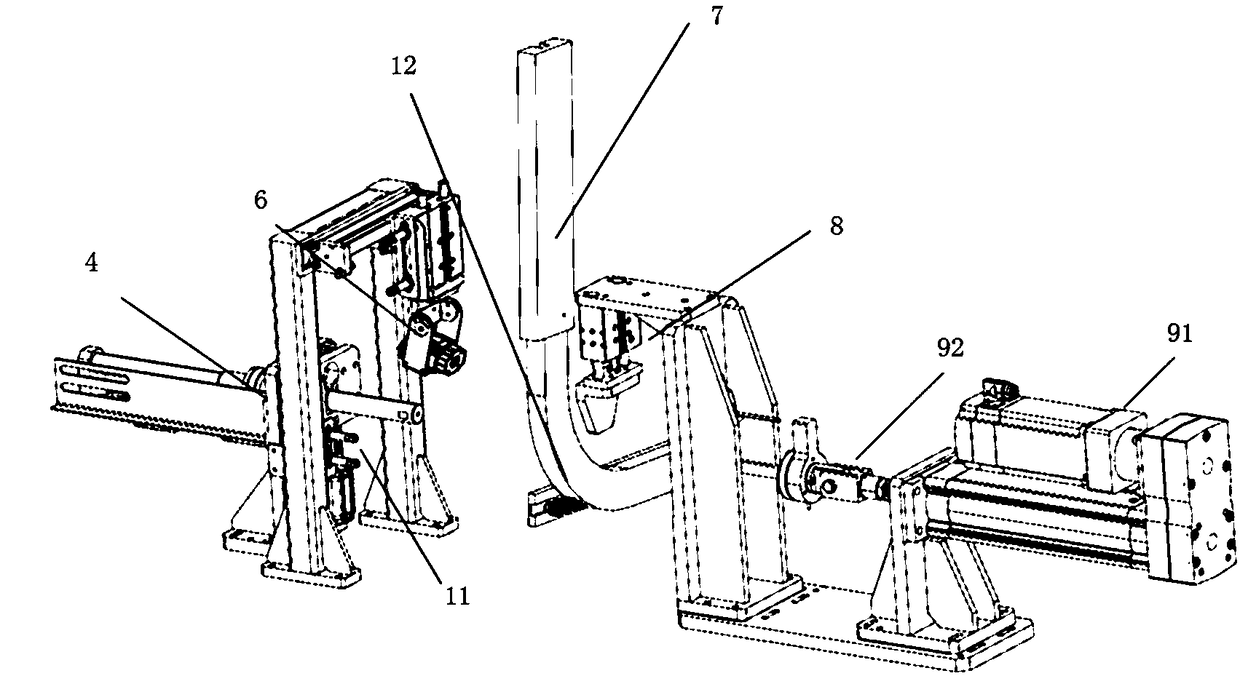

[0027] like Figure 1 to Figure 3 As shown, an error-proof magazine-type loading bearing automatic press-fitting mechanism includes a workbench 1 on which a stop and lift mechanism 5 for positioning the crankshaft 3 and a transport roller for transporting the crankshaft 3 are fixed. Road 2, feeding mechanism 7, scanning camera 6 for scanning two-dimensional code information on the crankshaft 3, side pressing mechanism 4, top pressing mechanism 8 and press-fitting mechanism 9, wherein, the feeding mechanism 7, scanning The camera 6 and the top pressing mechanism 8 are installed on the workbench 1 respectively, the side pressing mechanism 4 and the press-fitting mechanism 9 are arranged on both sides of the workbench 1 respectively, and the transport roller table 2 is suspended on the Above the workbench 1, the stopping and lifting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com