Yarn guide plate tilter for ring spinning frames

A technology of turning device and yarn guide plate is applied in spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problems of high labor intensity, long processing time and small location space, and reduce installation The effect of reducing workload, reducing labor intensity and speeding up installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

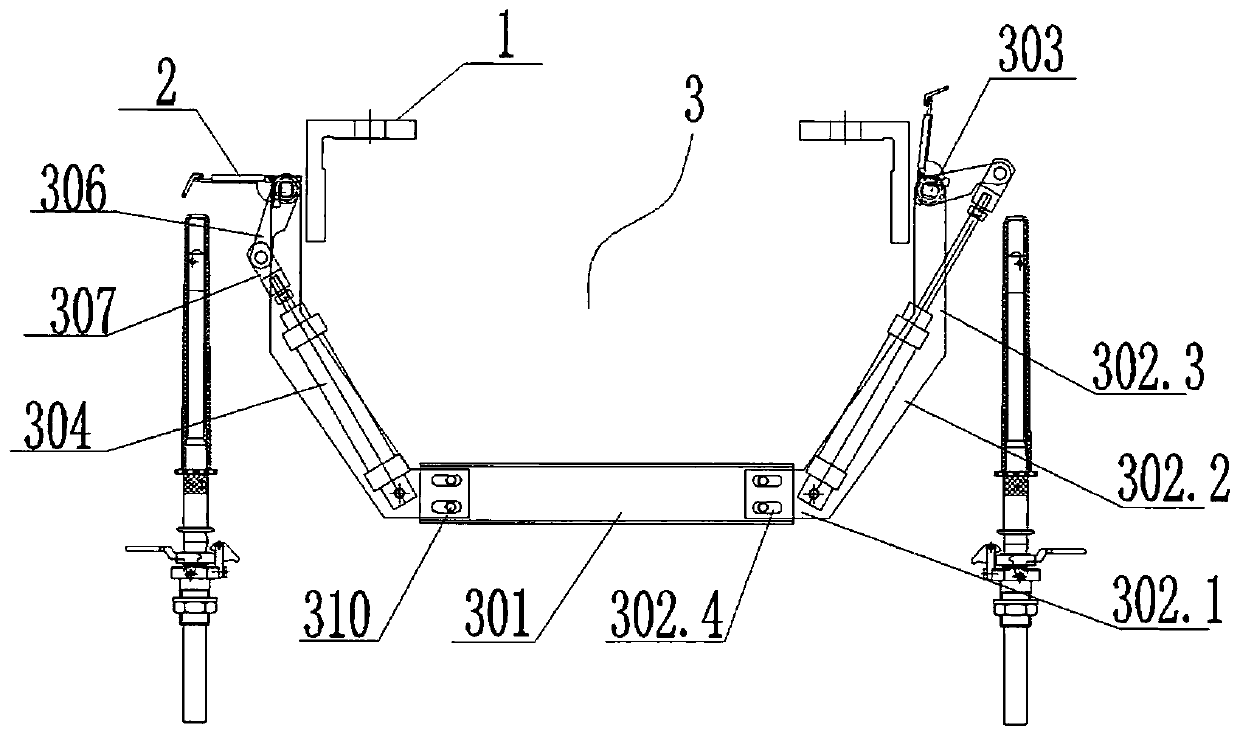

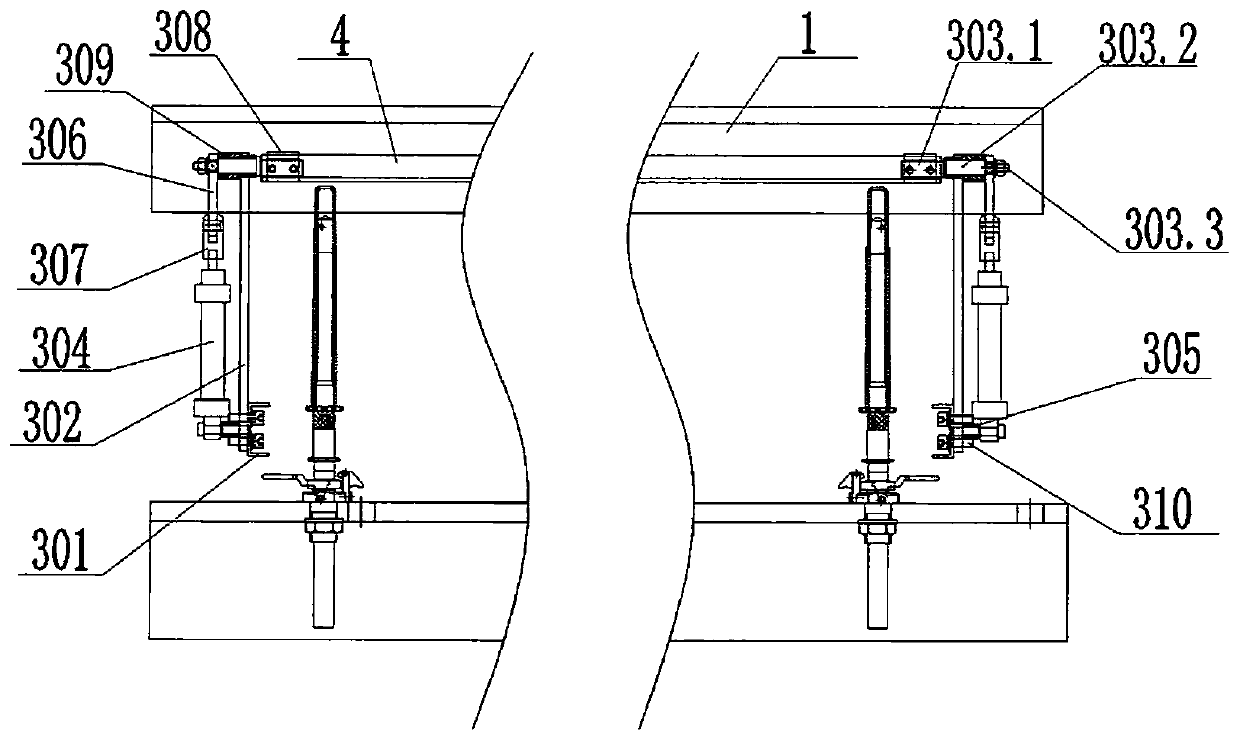

[0019] see Figure 1-Figure 2 , a ring spinning frame guide plate turning device related to the present invention, comprising a machine beam 1, an angle steel 4 is respectively arranged on the left and right sides of the machine beam 1, and a yarn guide plate 2 is arranged on the angle steel 4, so The bottom of the machine beam 1 is provided with two front and rear turning assemblies 3, which are respectively located on the front and rear sides of the angle steel 4. The turning assembly 3 includes a horizontally arranged fixed plate 301, and the two fixed plates 301 A support plate 302 is provided at each end respectively, the bottom end of the support plate 302 is connected with the outer end of the fixed plate 301, and the top end of the support plate 302 is connected with the outer end of the angle steel 4 through the connector 303, the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com