Device for rapidly detecting hole shift of boring cast-in-situ pile and using method thereof

A cast-in-situ pile and punching technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of long construction period of punched cast-in-place piles, large pile machine vibration, and difficult measurement, so as to reduce the measurement burden and reduce the The effect of reducing the number of measurements and reducing the difficulty of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further describe a device for quickly detecting the deviation of perforated cast-in-situ piles of the present invention and its use method, it will be further described below in conjunction with the accompanying drawings.

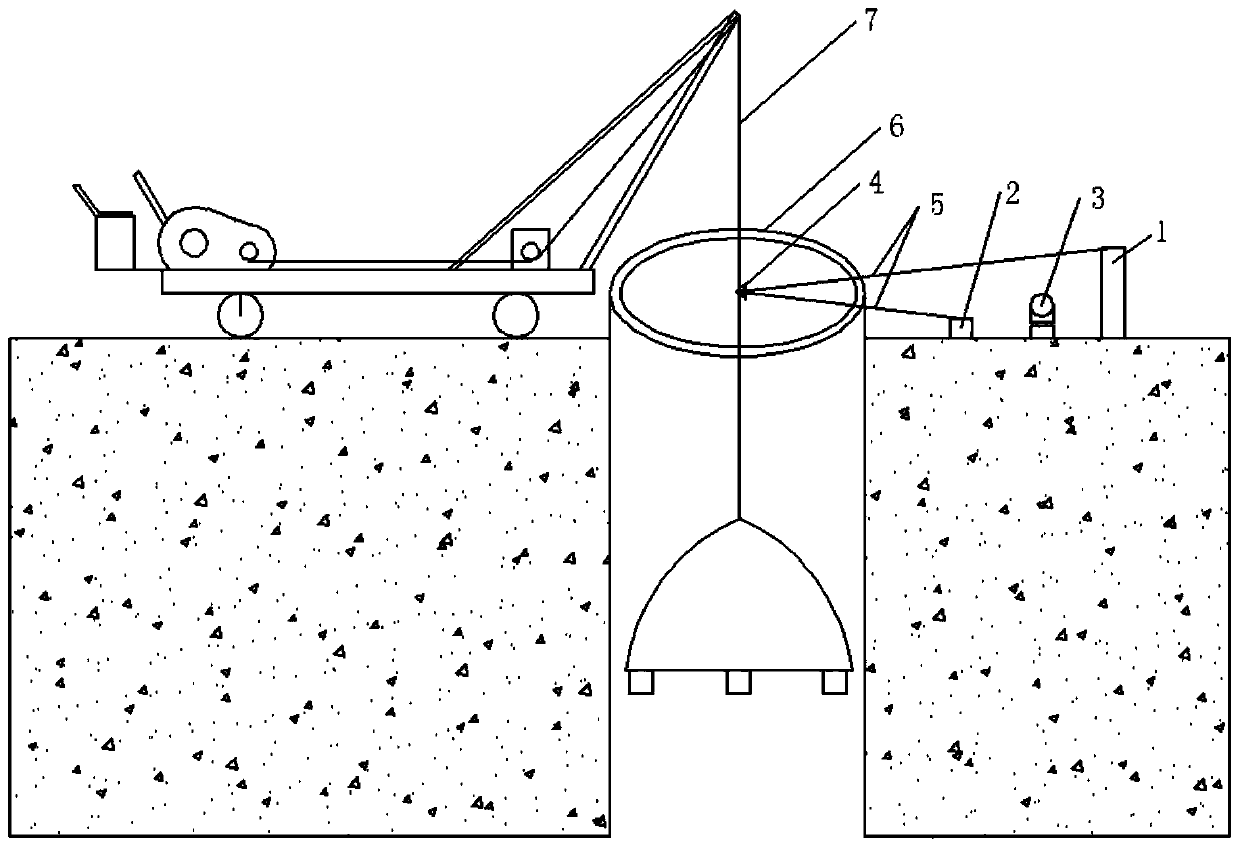

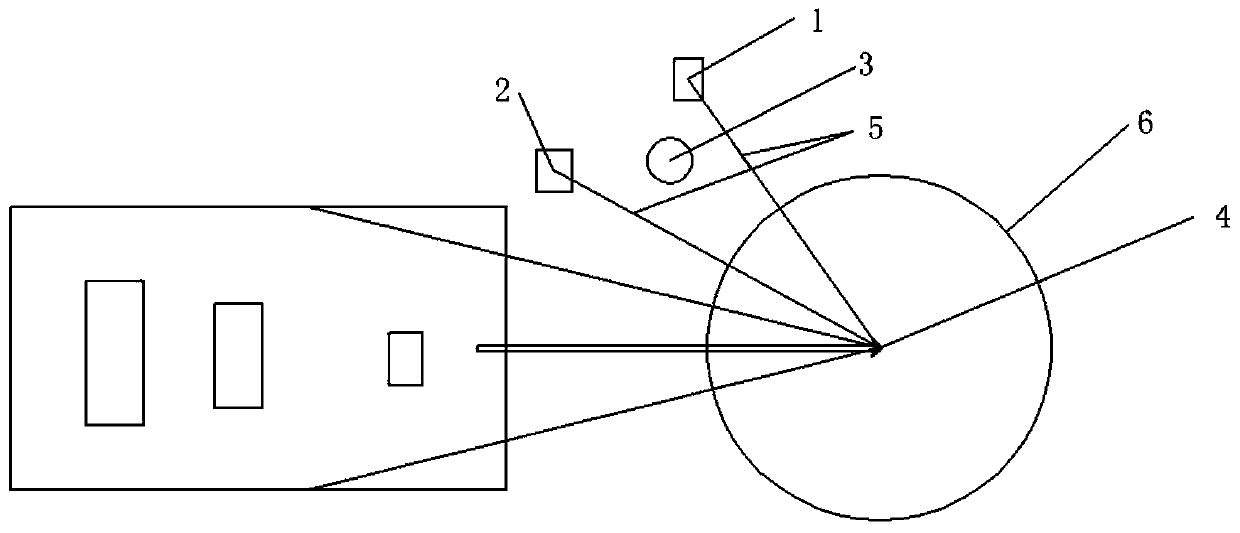

[0018] Figure 1-2 Middle: A device for quickly detecting the deviation of perforated cast-in-place piles, including perforated cast-in-place piles 6, hoisting wire ropes 7, first fixed point 1, second fixed point 2, laser infrared level 3, positioning clamp 4 and inelastic soft rope 5. The hoisting wire rope 7 is hung in the punched cast-in-place pile 6, the first fixed point 1 and the second fixed point 2 are respectively fixed on one side of the punched-in-place pile 6, and the inelastic soft rope 5 is two Respectively connect the first fixed point 1, the second fixed and positioning clip 4, the positioning clip 4 is clamped with the hoisting wire rope 7, the first fixed point 1, the second fixed point 2 and the positioning clip 4 form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com