Electronic element installing method

An electronic component installation and component technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as the inability to align the optical path, the expansion of mechanical errors, and the increase in the manufacturing cost of the placement machine, so as to achieve low difficulty in data processing and reduce measurement The number of times, the effect of improving placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

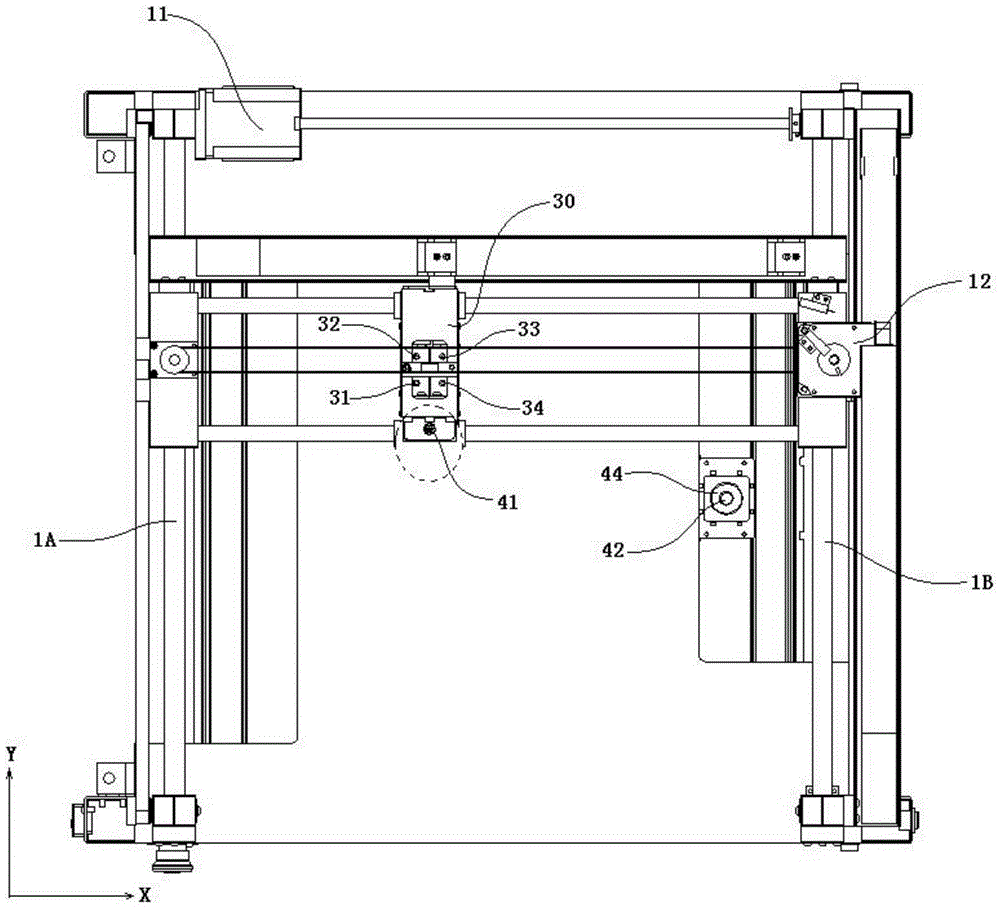

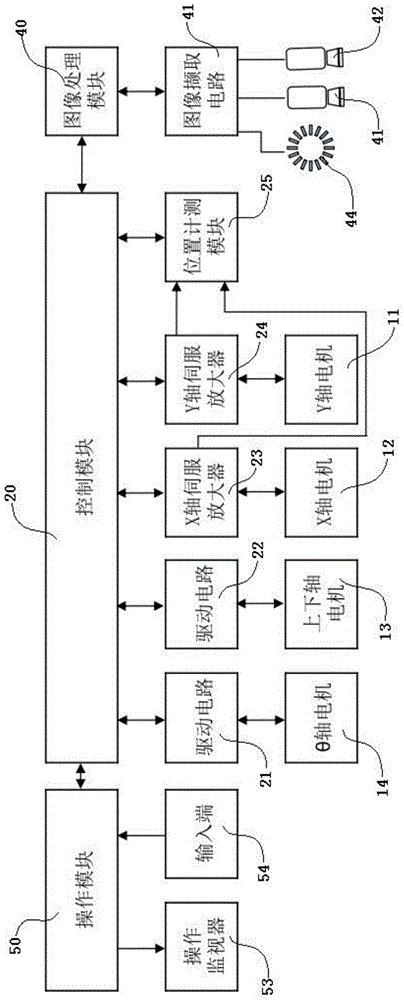

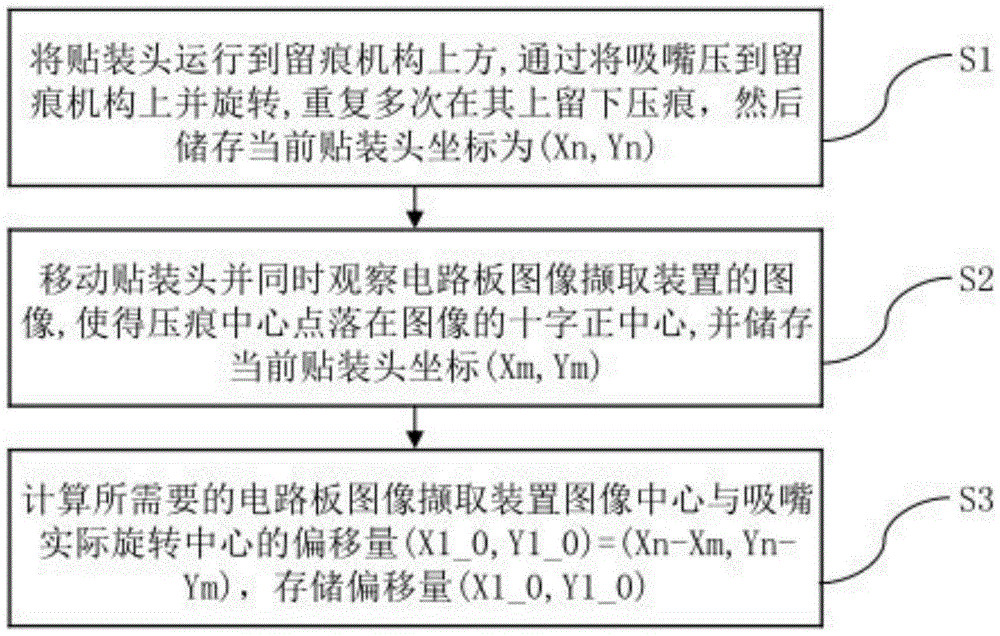

[0035] The desktop mounter is equipped with a conveying device for conveying printed circuit boards, a component supply device for supplying electronic components, a pair of arms 1A, 1B that can move in one direction (Y direction) by a Y-axis motor 11, and a pair of arms 1A, 1B that can be moved by an X-axis The motor 12 moves the placement head 30 along the two arms (X direction), and the X-Y coordinate system is the mechanical coordinate system of the placement head 30 .

[0036] Moreover, the suction nozzle 31 can be driven up and down by the vertical axis motor 13 via the drive circuit 22, and the suction nozzle 31 can be driven by the θ axis motor 14 via the drive circuit 21 to rotate around the vertical axis, so that the suction nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com