Novel assembly structure of air outlet pipe of automotive air filter

An air filter and assembly structure technology, which is applied in the directions of fuel air filter, combustion air/combustion-air treatment, charging system, etc., can solve problems such as cost reduction, achieve cost reduction, ensure effective thickness, improve The effect of product airtight reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

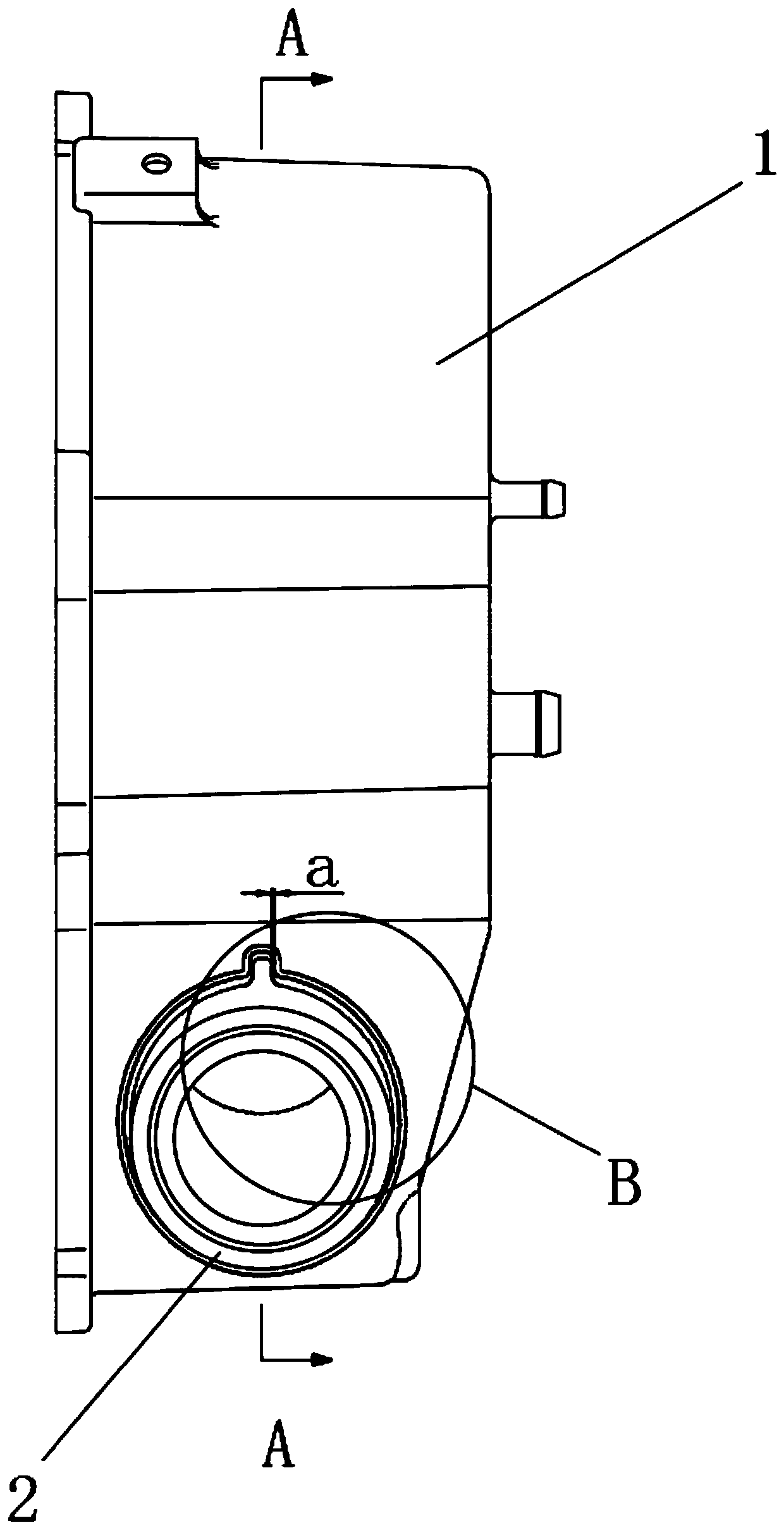

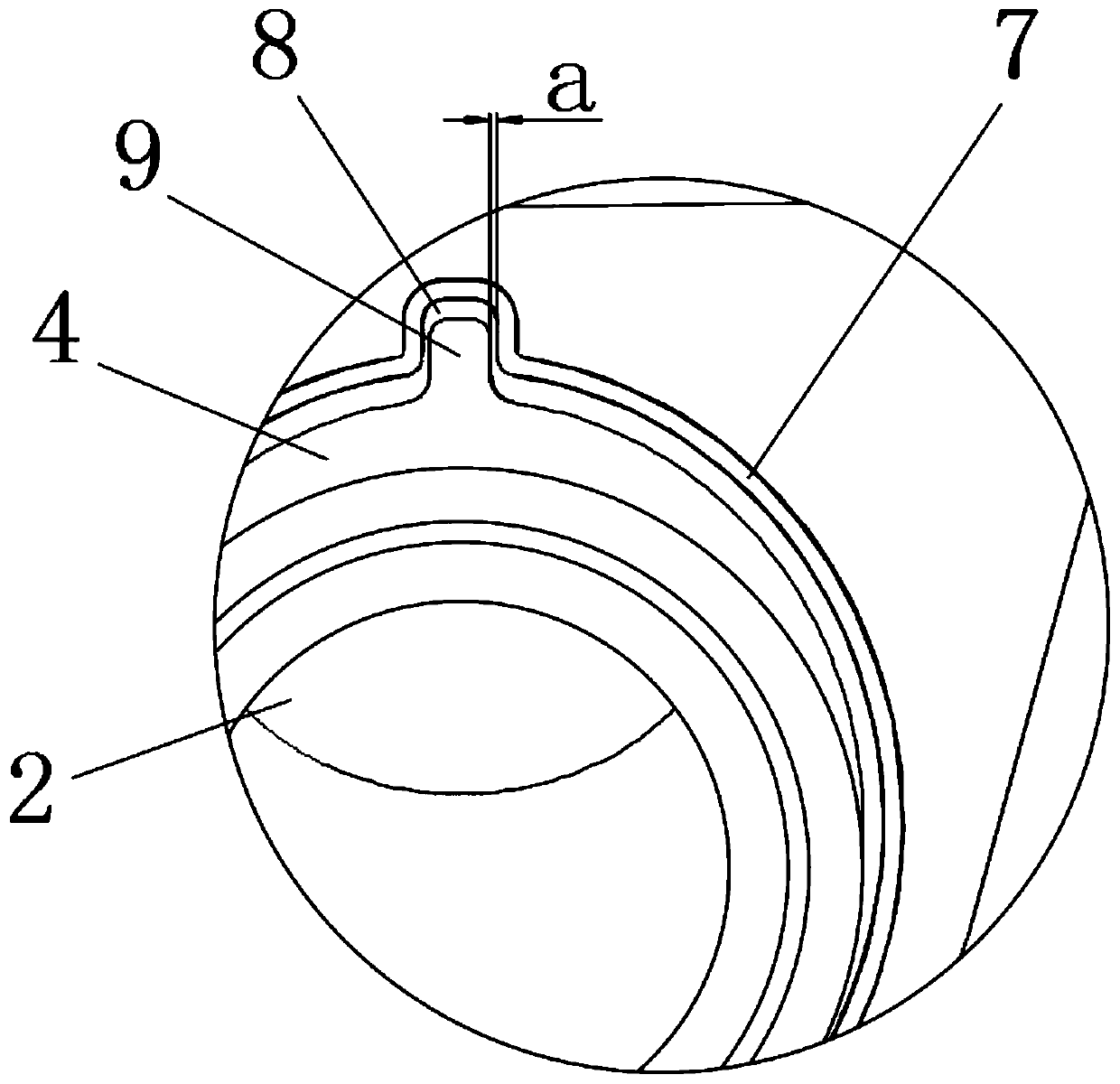

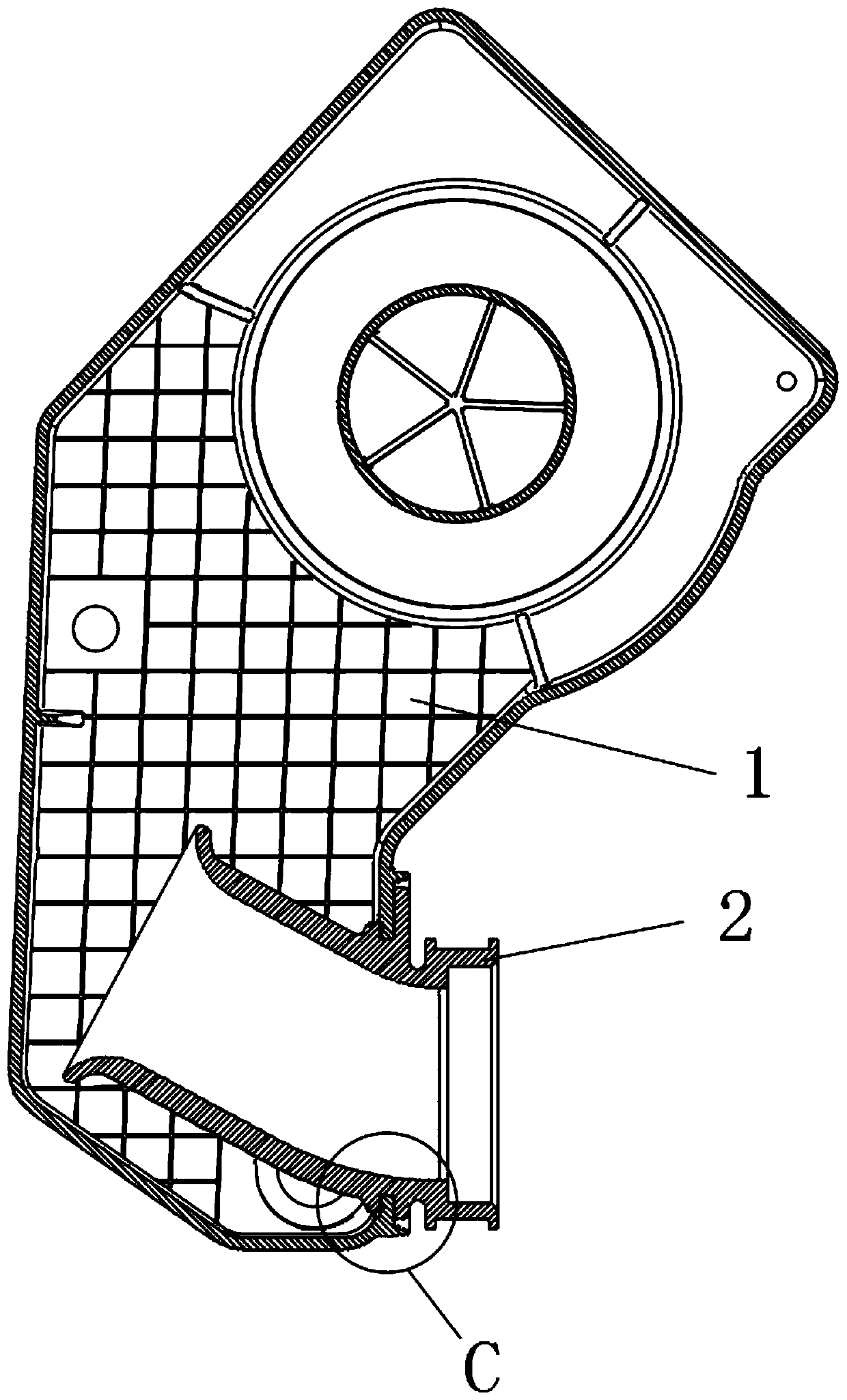

[0019] like Figure 1 to Figure 5 As shown, the present invention provides a vehicle air filter outlet pipe assembly structure, including an air filter body 1 and an air outlet pipe 2, the air filter body 1 is provided with a mounting hole 3, and the air outlet pipe 2 is inserted and installed In the hole 3, the outer pipe wall of the outlet pipe 2 is provided with a rib retaining portion 4 and an undercut positioning portion 5, and an accommodation groove 6 is formed between the rib retaining portion 4 and the undercut positioning portion 5, and the accommodation groove 6 The width of the bottom is equal to the wall thickness of the air filter body 1 at this place, and the upper part of the undercut positioning part 5 close to the side wall of the air filter body 1 is inclined outward so that the width of the upper part of the receiving groove 6 is smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com