Intelligent infrared digital panoramic system and warehouse management method thereof

A digital panorama and infrared technology, applied in the field of warehouse management, can solve problems such as high error rate, long cycle, and slow inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The invention provides an intelligent infrared digital panorama system, which includes a barcode recognition device, a sky eye device and a data processing device. The infrared digital panorama system is used to monitor and manage the incoming and outgoing goods in the warehouse, and can also monitor the goods stored in the warehouse.

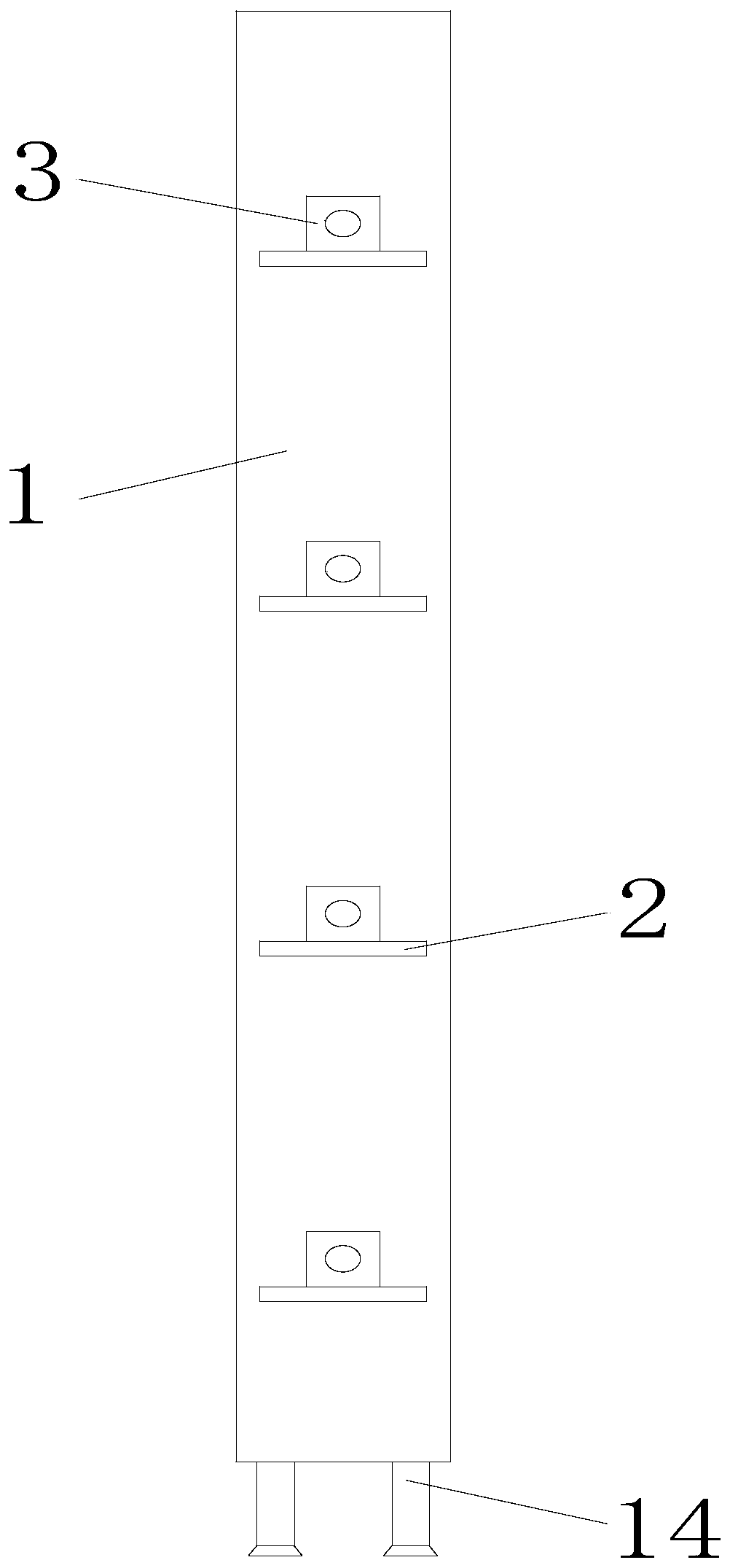

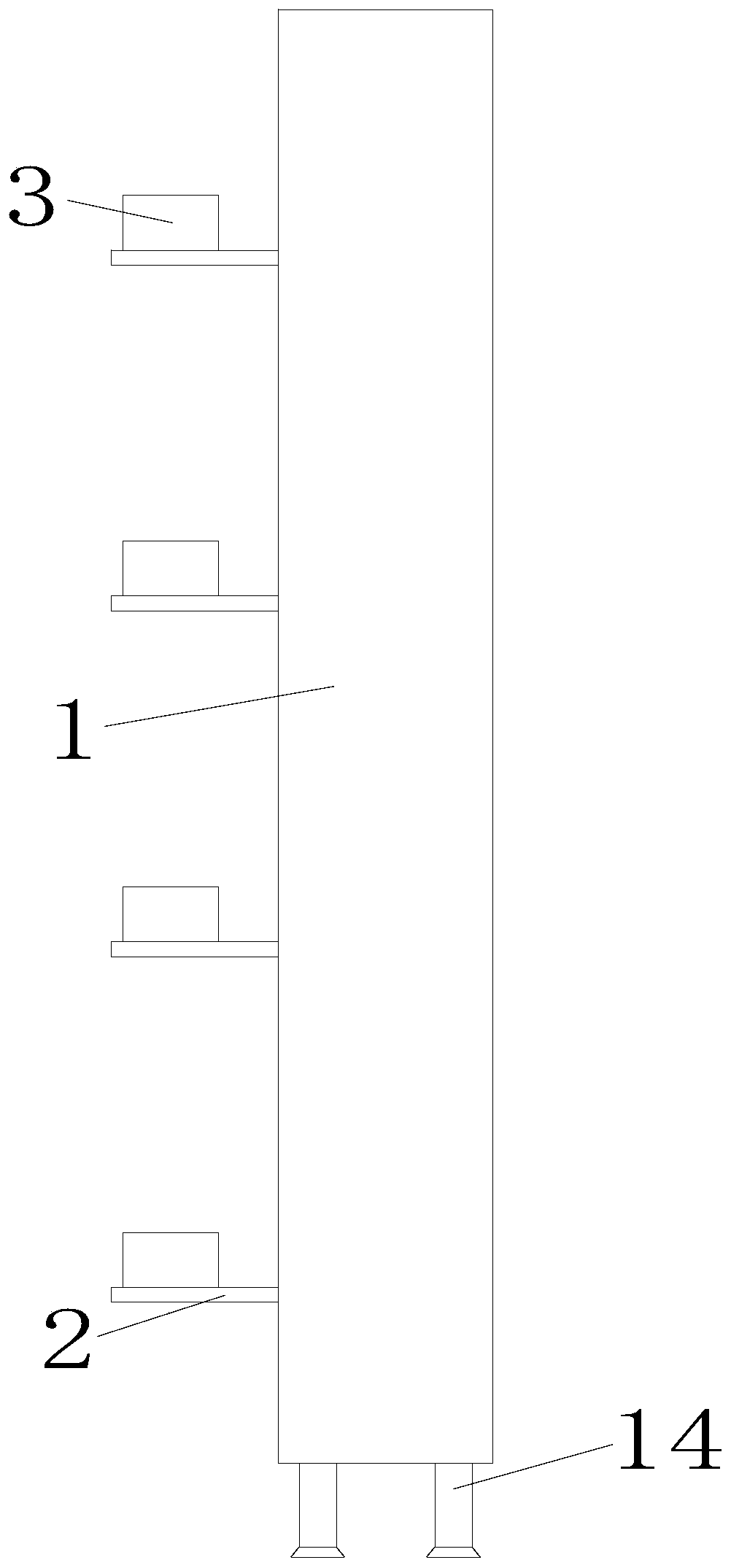

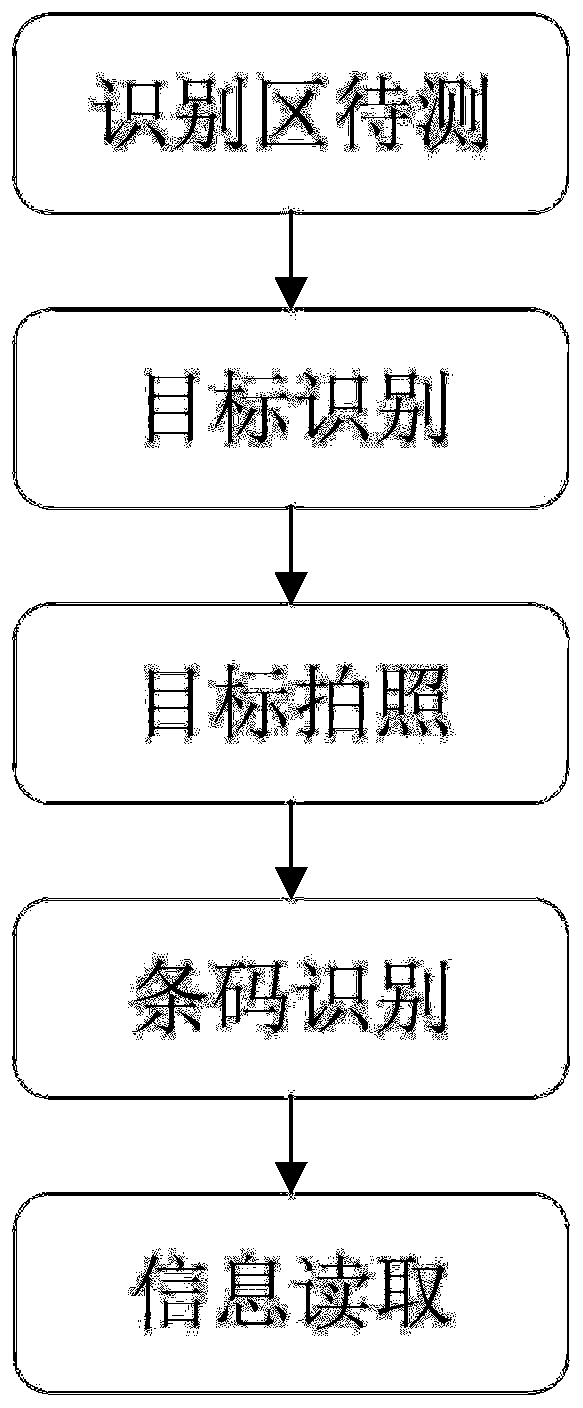

[0066] see figure 1 , figure 2 as well as image 3 According to the research conducted by the inventor of this case, the traditional warehousing process is: unloading of the clamping truck → manual scanning of the code in the temporary storage area → warehousing of the clamping vehicle. Therefore, this embodiment proposes a barcode recognition device. The barcode recognition device includes a support rod 1 , a barcode recognizer, a plurality of support plates 2 and a plurality of cameras 3 , and may also include a base 14 . The same ends of the plurality of support plates 2 are all fixed to the support pole 1, and the support pole 1 ...

Embodiment 2

[0112] see Figure 12 , this embodiment provides an intelligent infrared digital panorama system, which adds a storage location matching device on the basis of Embodiment 1. Wherein, the storage location matching device includes a storage location optimization allocation model module and a storage location matching module.

[0113] According to the current defects in warehouse management, we realize that the improvement of warehouse management information technology is the basis and guarantee for efficient warehouse management. Therefore, this embodiment combines modern information technology to establish a warehouse location matching system. In the warehouse-in process, we obtain the goods information such as the model and specification of the goods at this time according to the barcode identifier, and connect to the database; Optimal warehouse location, the system guides the forklift and clamp truck drivers to place the goods to the designated warehouse location through voi...

Embodiment 3

[0131] This embodiment provides an intelligent infrared digital panoramic system, which is refined on the basis of Embodiment 2. The guide rail material of this embodiment mainly adopts No. 45 steel. The inner track (the track closest to the symmetrical plane of the slide rail) needs to adopt a shape that fits the inner wheel (if possible, it can be made into a gear), and wear-resistant steel is used; the material of the slide rail and crossbar needs to be determined after the quality of the wires and motors calculate.

[0132] 1. On the part of the guide rail 5:

[0133] m=m 电机 +m 材料 +m 轴 +m 线

[0134]

[0135] b 1 : width h 1 :high

[0136] Need to meet: E max ≤[σ] allowable stress is sufficient.

[0137] 2. On the part of beam 11:

[0138] S=dl m: Motor quality d: Length of upper table l: Width of lower table

[0139]

[0140] where: b 1 : outer width b 2 : inner width h1 : Outer height h 2 : inner height

[0141] Need to meet: E max ≤[σ] allowab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com