Heat-conducting oil heating device with cooler

A heat transfer oil heater and heating device technology, which is applied in the direction of heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems that the heat transfer oil heating device cannot cool down the heat transfer oil, and cannot meet the needs of rapid cooling, and achieves Prevent the oil temperature from being too high, improve the cooling effect, and realize the effect of rapid cooling in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

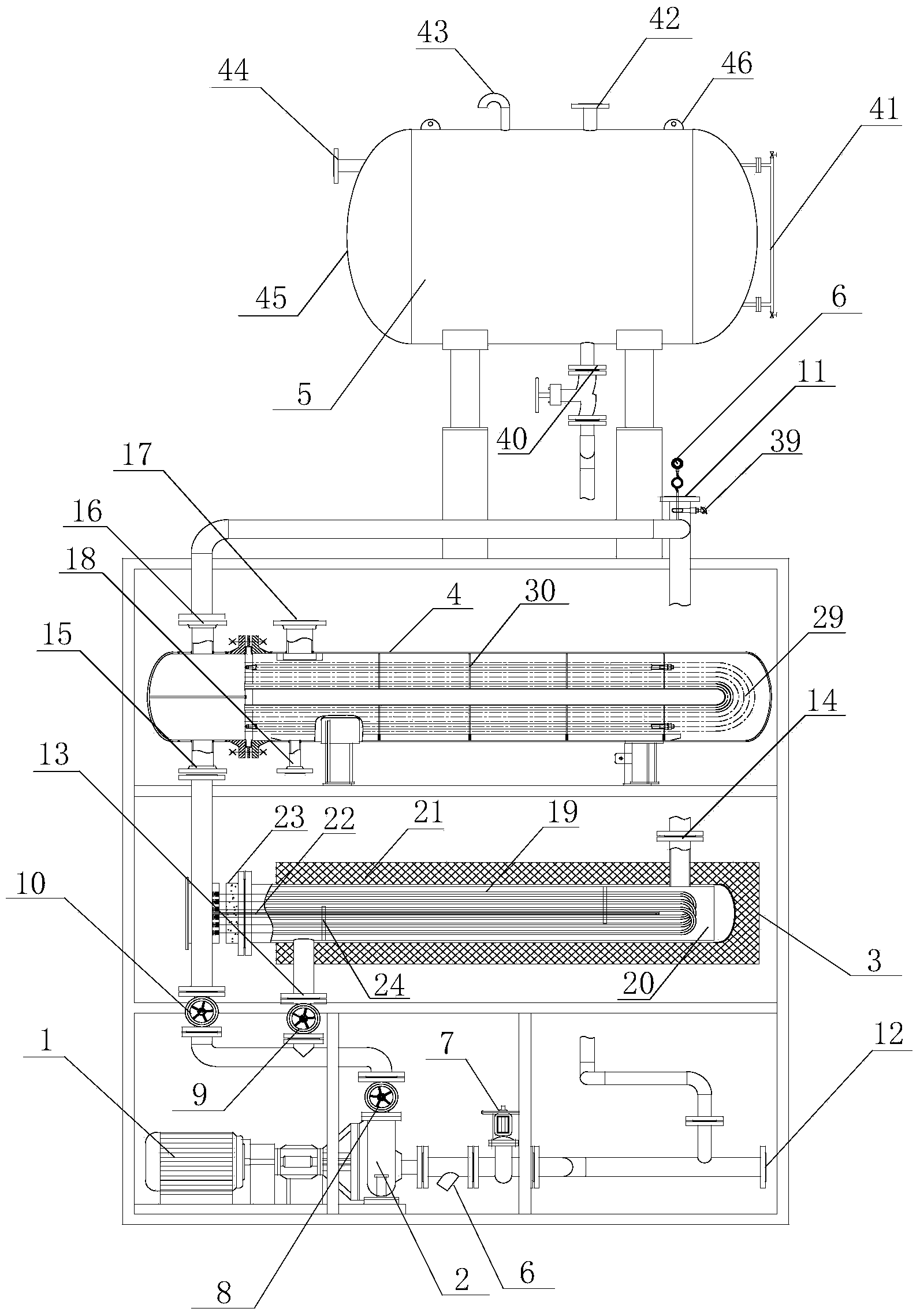

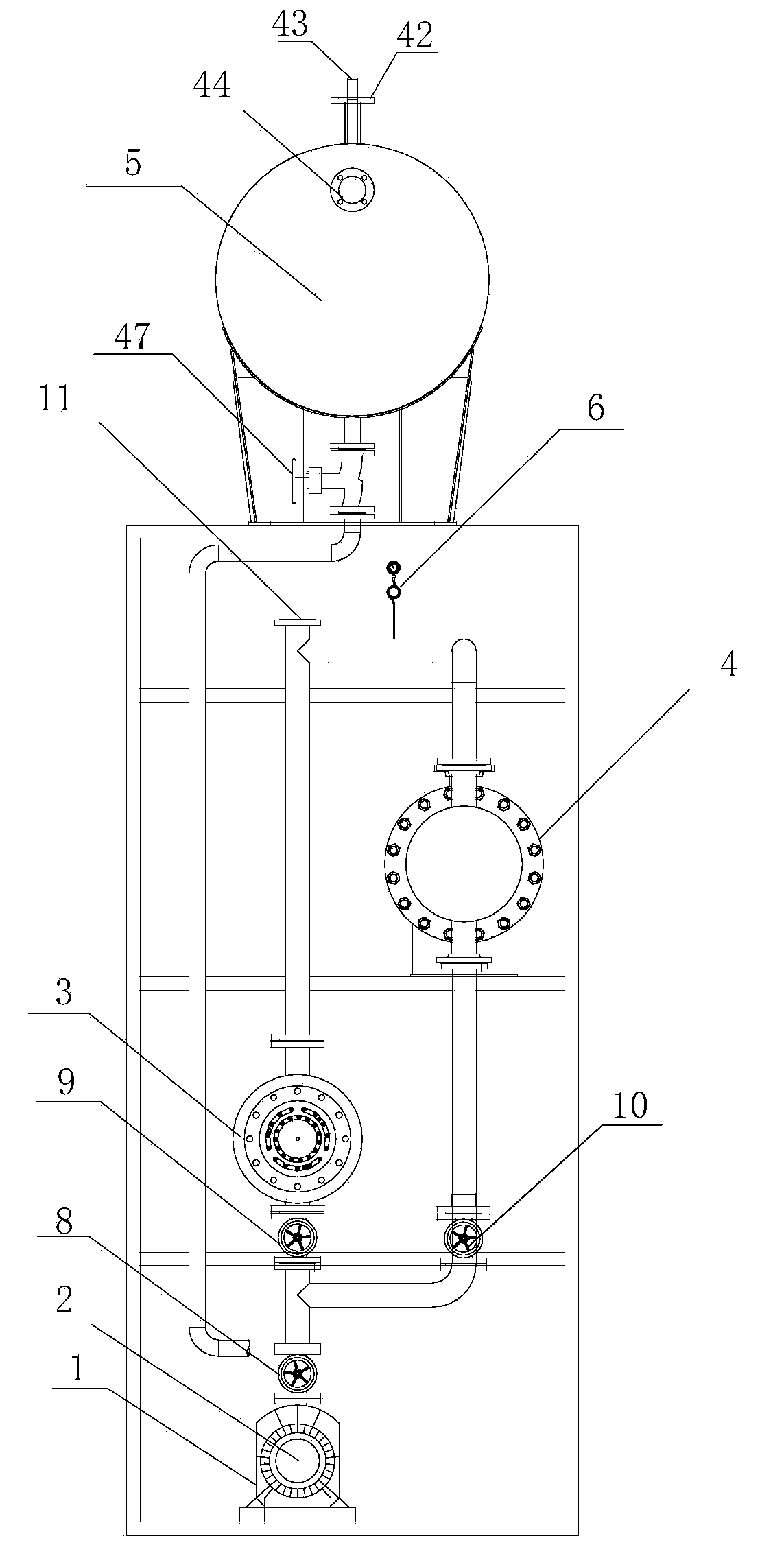

[0035] Such as figure 1 , 2 , 3, 5 and 9, the heat transfer oil heating device with cooler of the present invention includes a drive motor 1, an oil pump 2, a heat transfer oil heater 3, a cooler 4 and an expansion tank 5,

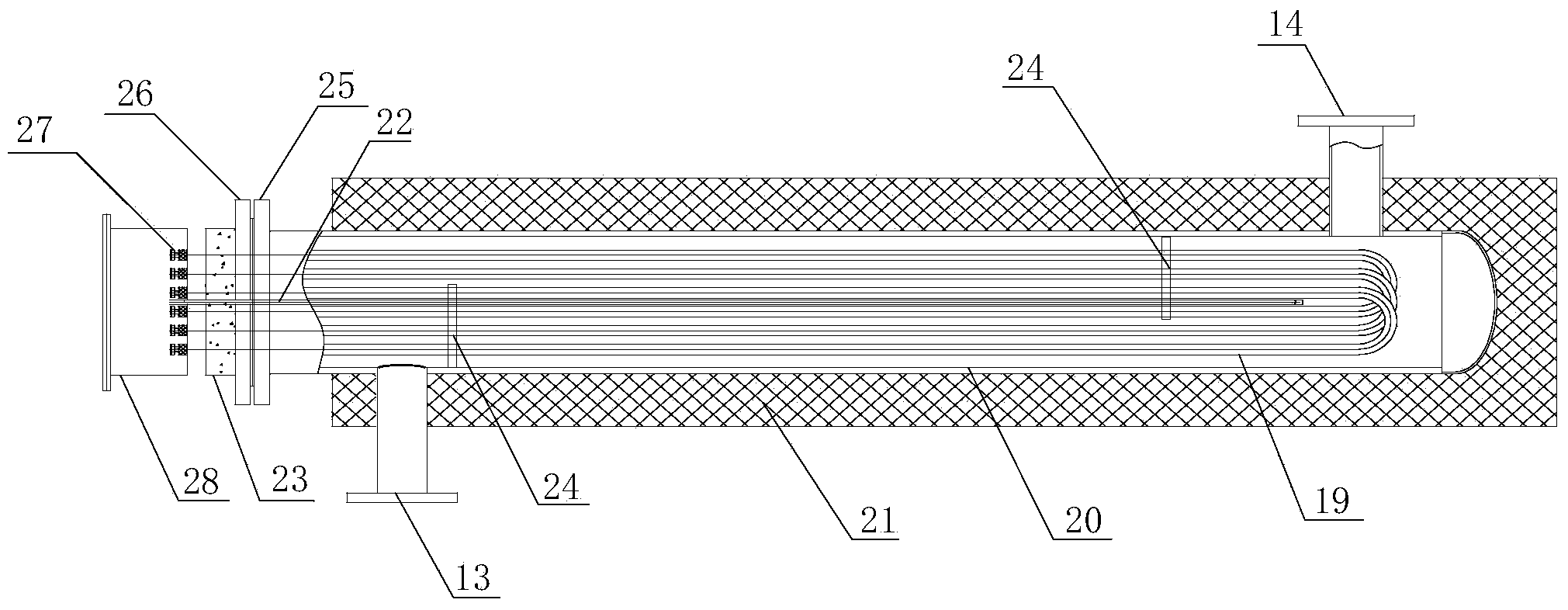

[0036] Wherein, the heat conduction oil heater 3 includes a heating chamber 20 and a heater. The heating chamber 20 is a cylindrical chamber placed horizontally. A heating oil inlet 13 is provided on the lower side of one end of the heating chamber 20, and a heating oil inlet 13 is provided on the upper side of the other end. There is a heating oil outlet 14, wherein the heating oil inlet 13 is optimally arranged near the opening of the heating chamber 20, and the heating oil outlet 14 is optimally arranged at the bottom of the heating chamber 20, and the outside of the heating chamber 20 is provided with a thermal insulation shell 21, which can be Insulation cotton is stuffed in the metal shell to form an insulation shell 21. The opening of the heating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com