Filtering connector with electromagnetic compatibility effect

A filter connector, electromagnetic compatibility technology, applied in the direction of connection, high-frequency structural connection, connection device components, etc., can solve the problem that the CE102 and RE102 indicators cannot meet the system-level requirements, and the shielding treatment method cannot meet the system-level electromagnetic Compatible with index requirements and other issues to achieve the effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

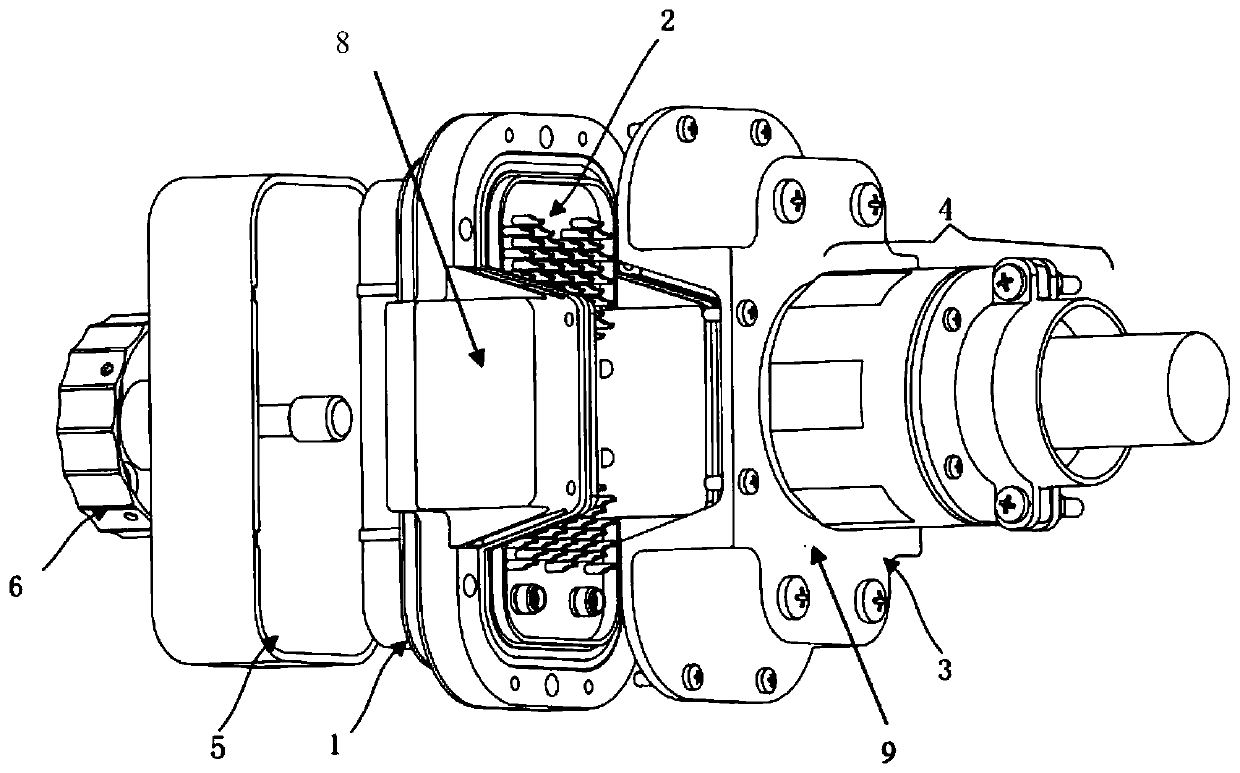

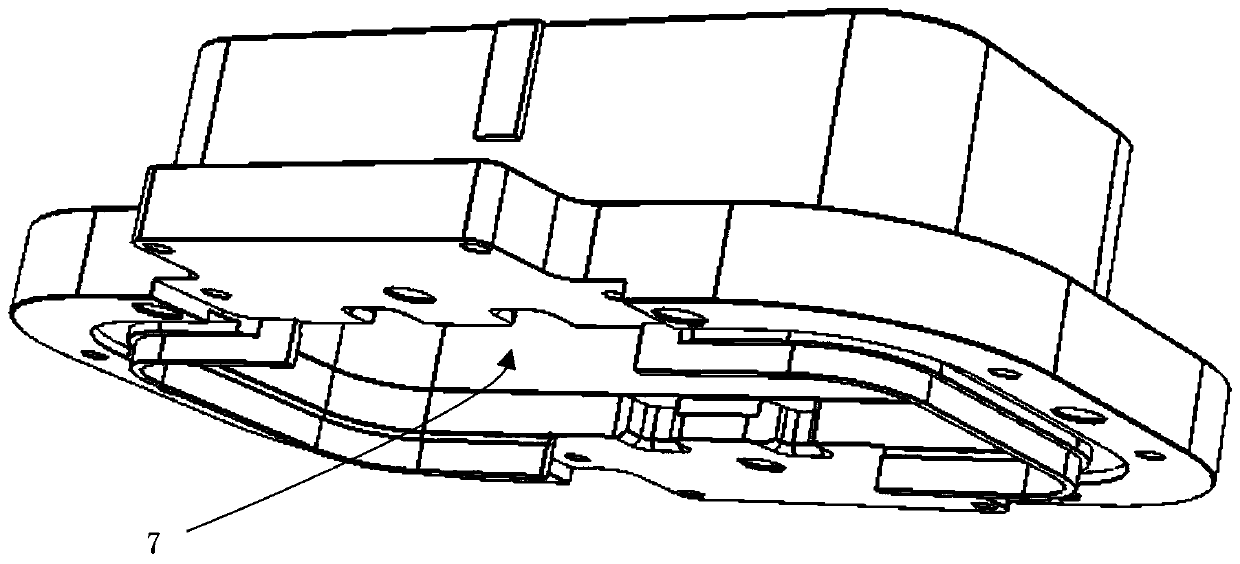

[0031] This embodiment provides a filter connector with electromagnetic compatibility, such as figure 1 with figure 2 As shown, it includes a filter connector body and a filter assembly 8 integrated on the filter connector body. The filter connector body includes a housing 1, a mounting plate, a contact assembly 2 and a printed circuit board; the mounting plate is arranged in the housing 1, and The board is set on the top of one side of the shell 1; the outer shell 1 is provided with a flange, and the two sides of the flange are provided with detachable filter components 8; the contact assembly 2 is provided on the mounting plate, and the mounting plate is also provided The first point contact, the second point contact, the third contact, and the fourth point contact. The filter assembly 8 adopts a π-type circuit and is in contact with the printed board, wires, and the first point to the fourth point. The whole circuit is connected with the filter connector.

[0032] Specificall...

Embodiment 2

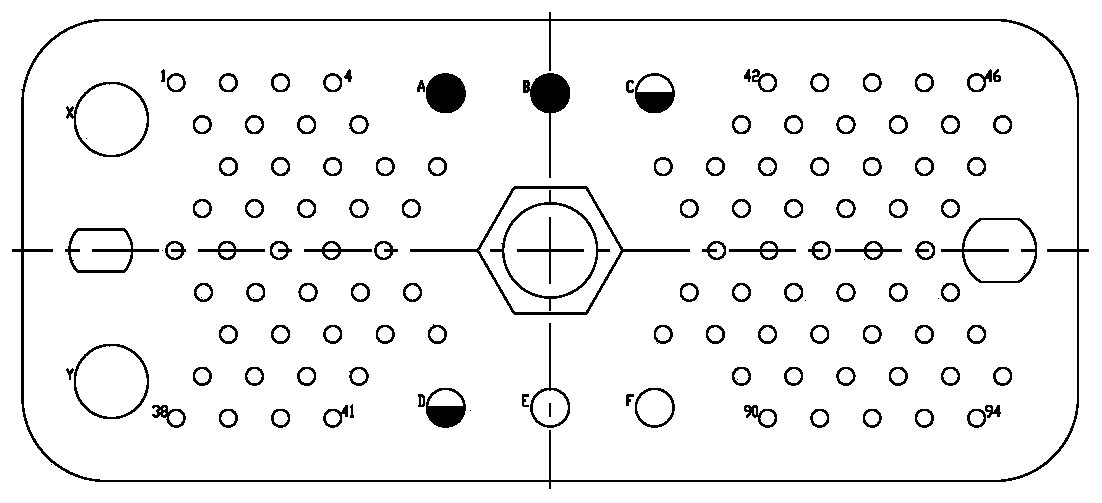

[0045] The design principle of the filter circuit in the filter component 8 of the present invention is as attached Figure 5 As shown, in order to meet the product's insertion loss index, that is, the CE102 test required by GJB151B-2013, the insertion loss in the 200kHz~30MHz frequency band, the common mode and differential mode are not less than 25dB; according to the RE102 test requirements of GJB151B-2013 Test, such as Figure 5 As shown, it meets GJB151B-2013.

[0046] The above-mentioned filter component 8 uses a π-type circuit, where L1, L2, L3, L4>10mH; C1=C2=C3=1μF; C4=C5=47nF; Figure 5 As shown in the schematic circuit diagram, the calculation indicators of the insertion loss of CE102 and RE102 of the filter component 8 designed in the present invention are shown in Table 1 and Table 2, respectively:

[0047] Table 1 CE102 test filter component 8 insertion loss calculation index

[0048]

[0049] Table 2 Measured value of insertion loss of filter component 8

[0050]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com