Buckling type positioning component for circular seam welding machine and circular seam welding machine

A technology for positioning parts and girth welding machines, which is applied to welding equipment, workpiece edge parts, auxiliary welding equipment, etc., and can solve problems such as difficult positioning of parts to be pressed reliably, poor welding operation of girth welding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

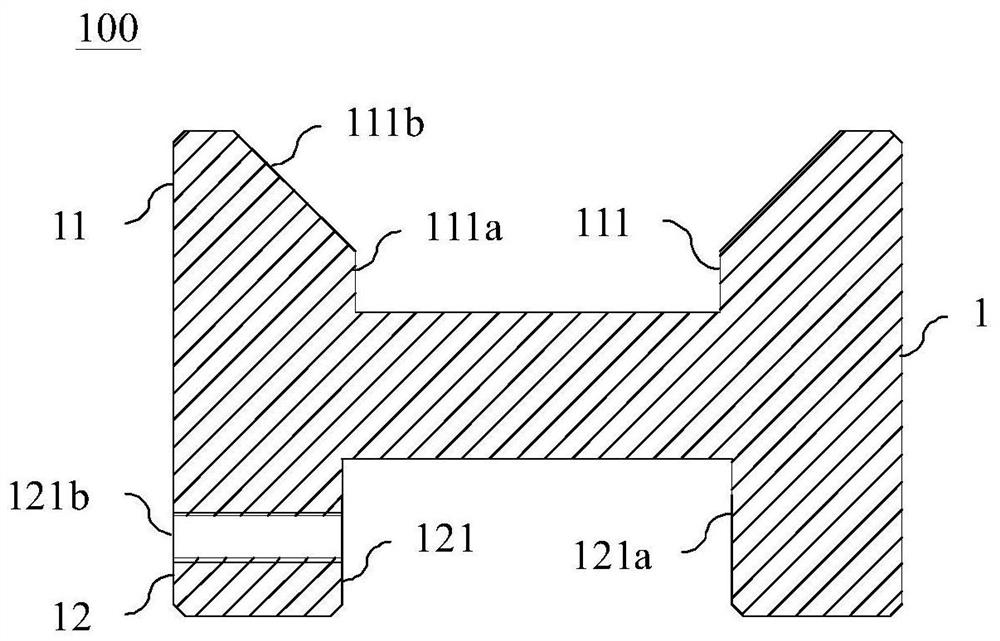

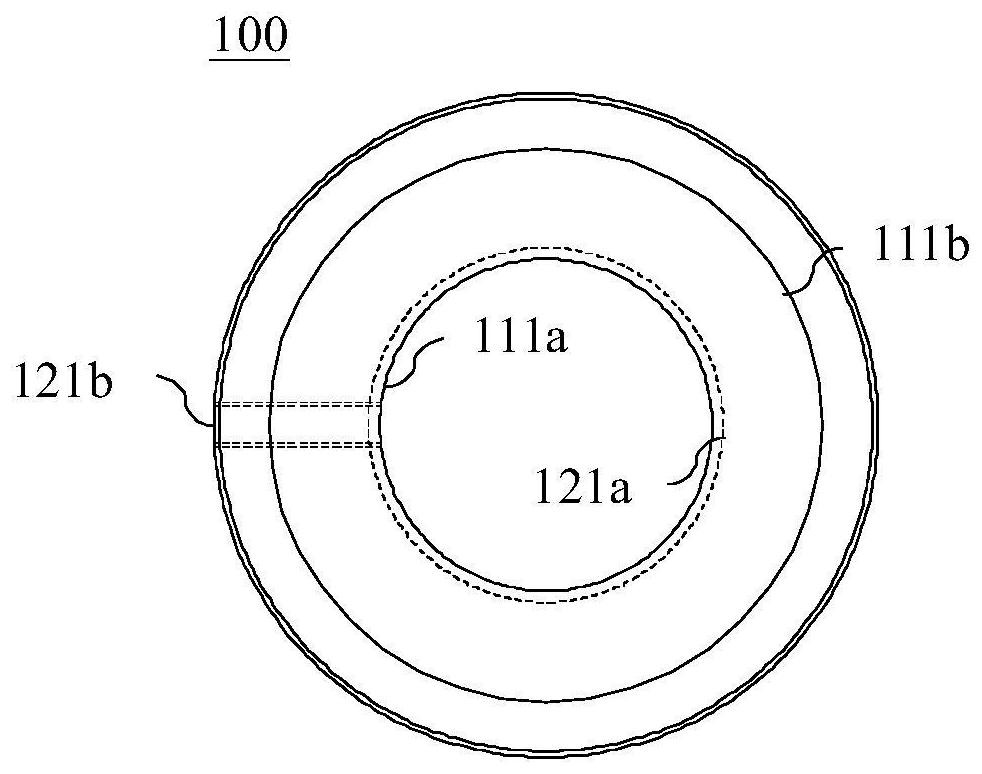

[0021] figure 1 It is a cross-sectional view of the buckle type positioning part used in the girth welding machine according to the embodiment of the present invention, figure 2 It is a top view of the buckle type positioning part used in the girth welding machine according to the embodiment of the present invention. Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a buckle-type positioning component 100 used in a girth welder, which includes a component body 1, the component body 1 includes a positioning end 11 and an The fixed end 12 connected to the welding machine and the positioning groove 111 provided on the positioning end 11, wherein the positioning groove 111 can partially accommodate the parts to be pressed in the assembly to be welded and prevent them from moving along the radial direction of the positioning groove 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com