Explosion-proof control cabinet

A technology for controlling cabinets and cabinets, which is applied in the direction of cabinet/cabinet/drawer parts, electrical equipment casing/cabinet/drawer, cooling/ventilation/heating transformation, etc., which can solve external safety accidents and reduce explosion-proof control Problems such as the service life of electrical components in the cabinet, to achieve the effect of preventing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

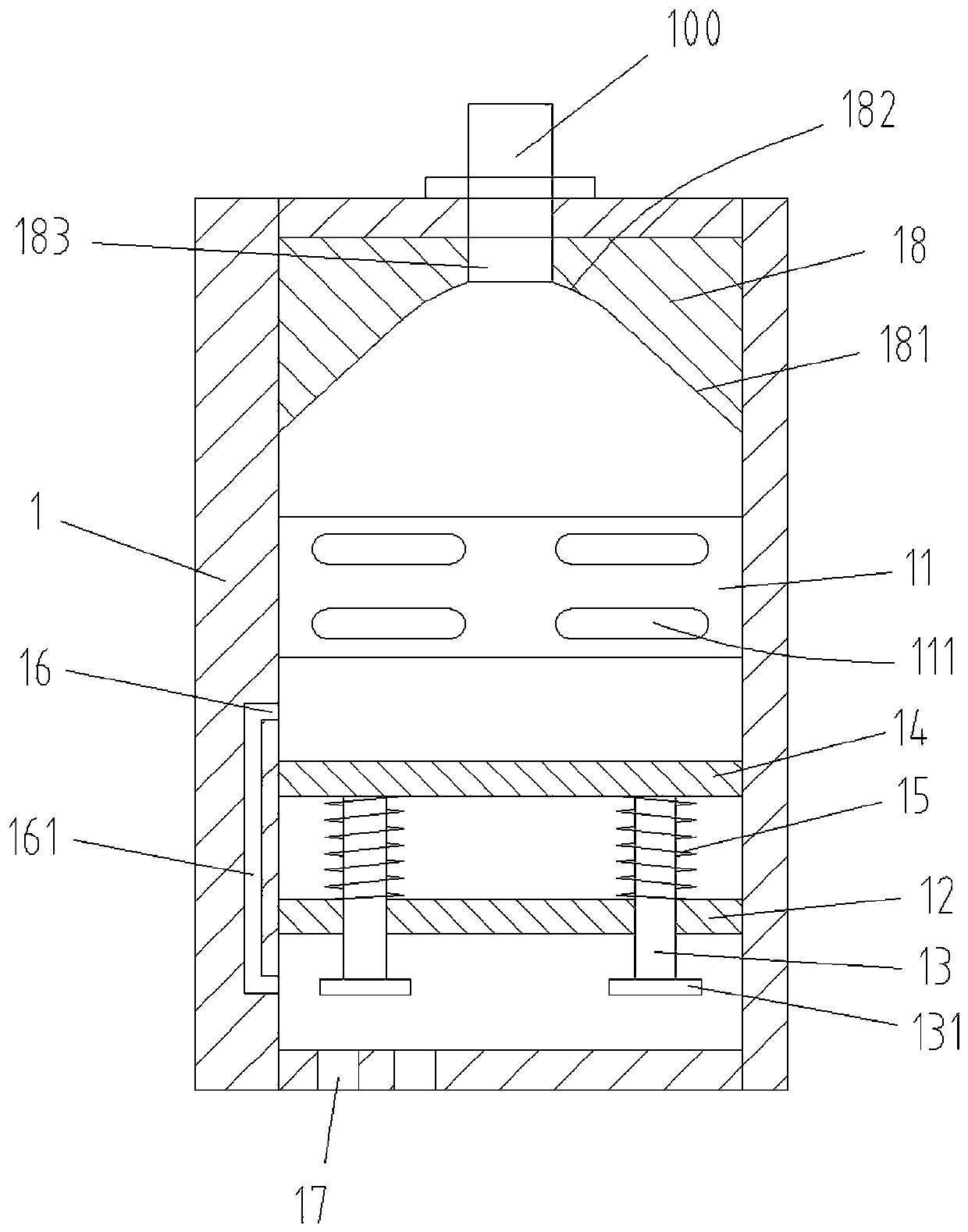

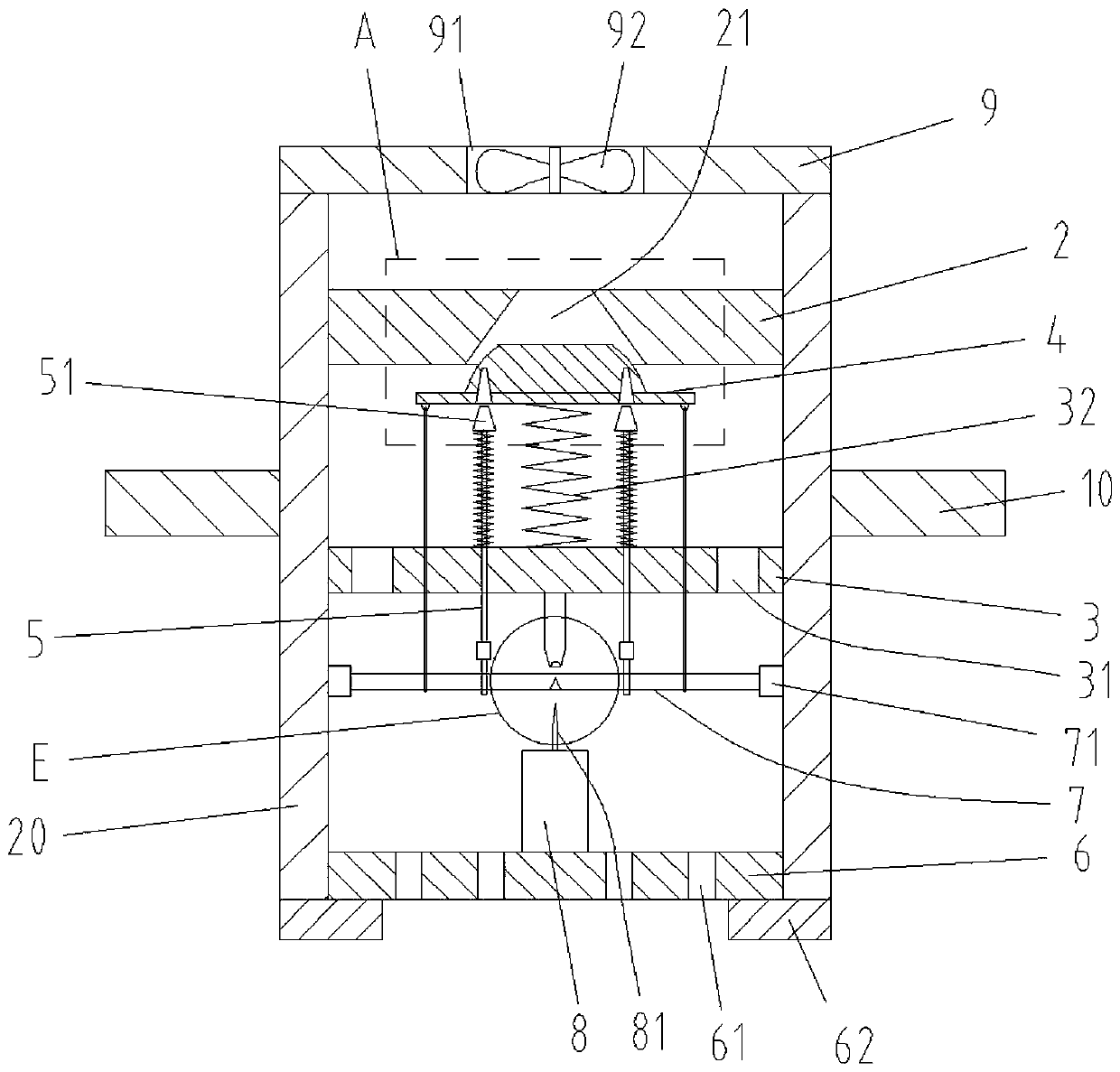

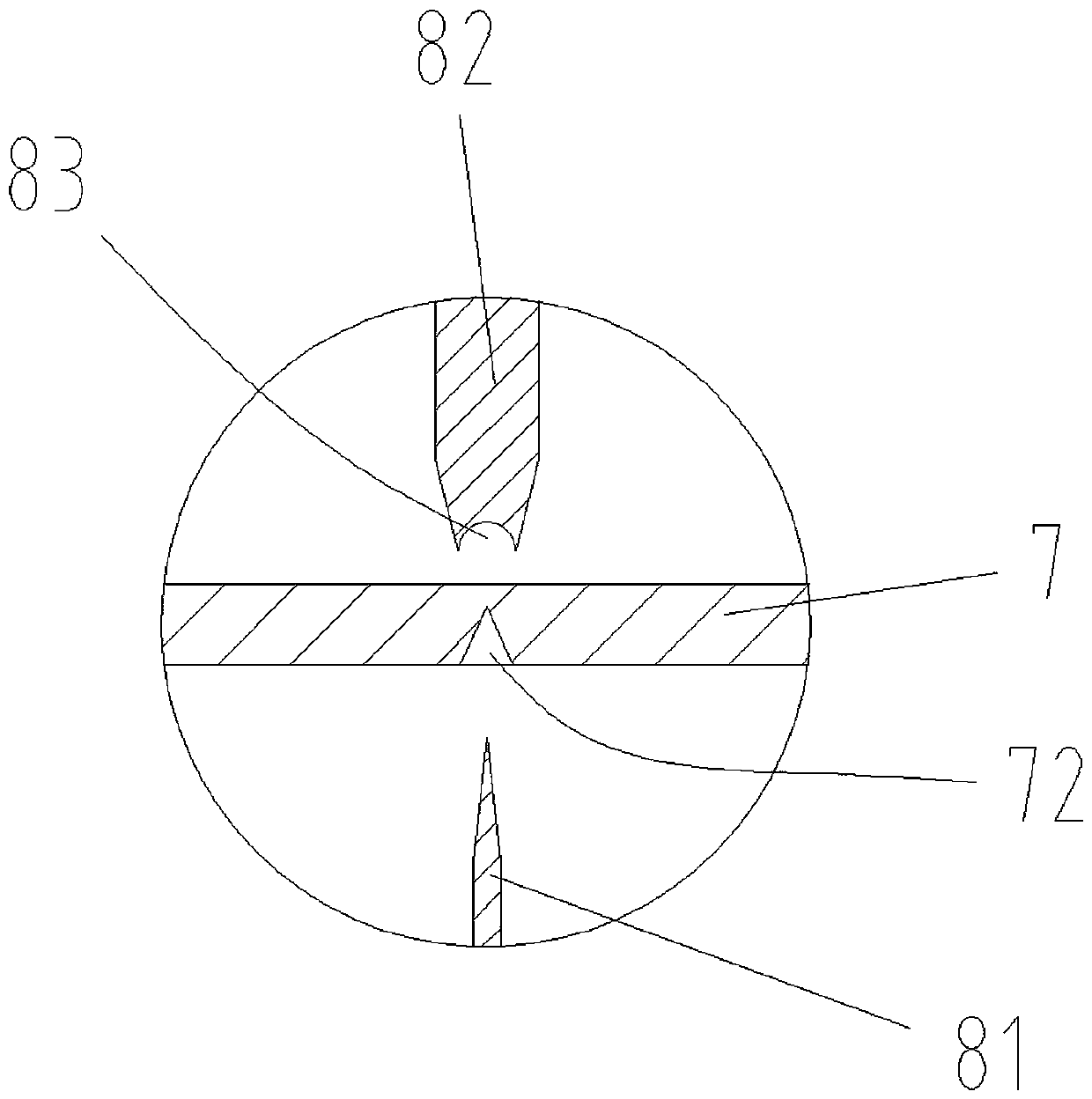

[0022] Such as Figure 1-Figure 4 As shown, an explosion-proof control cabinet provided by the present invention, an explosion-proof control cabinet, includes a cabinet body 1, and the middle part of the inner side of the cabinet body 1 is fixedly connected to the mounting seat 11, and a group of straight circular slot holes 111 are provided on the mounting seat 11. The top of the cabinet body 1 is provided with a central hole, and an exhaust valve 100 is installed at the central hole. The exhaust valve 100 includes a circular tube-shaped valve body 20 , and the bottom of the valve body 20 is fixedly connected with a retaining ring 62 . The top of the valve body 20 is fixedly connected to the top plate 9, the top plate 9 is provided with a fan hole 91, the fan hole 91 is equipped with a fan 92, the fan 92 adopts an axial flow fan, the air outlet of the axial flow fan is set upward, and the outer side of the valve body 20 is sleeved and fixed Mounting plate 10.

[0023] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com