Anti-explosion container with shielding and anti-theft function

A technology of containers and functions, applied in the field of anti-explosion containers with shielding and anti-theft functions, can solve problems such as explosions, potential safety hazards, and the inability of containers to form airtight conductors, and achieve the effects of improving safety performance, good protection, and good anti-theft functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

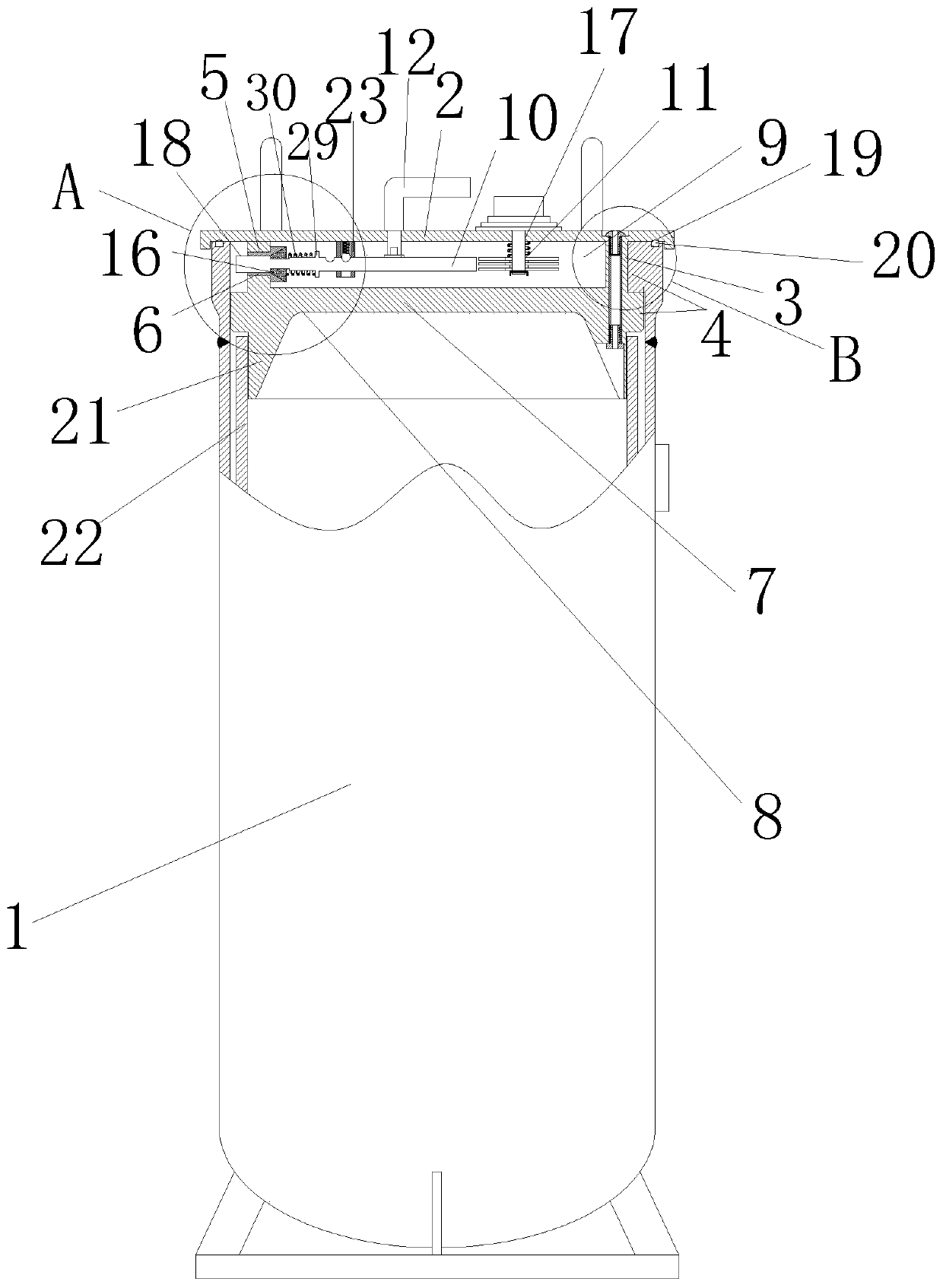

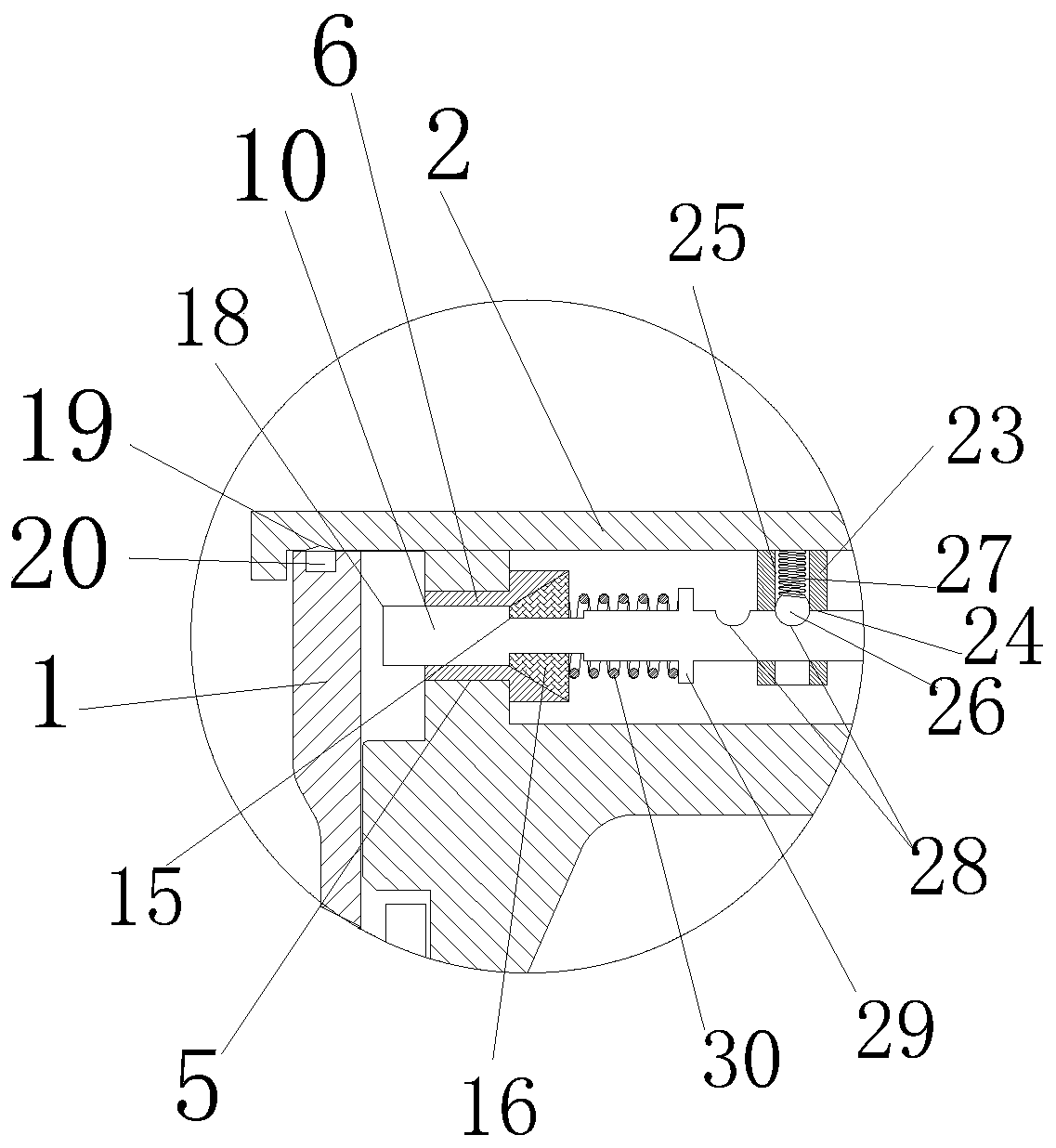

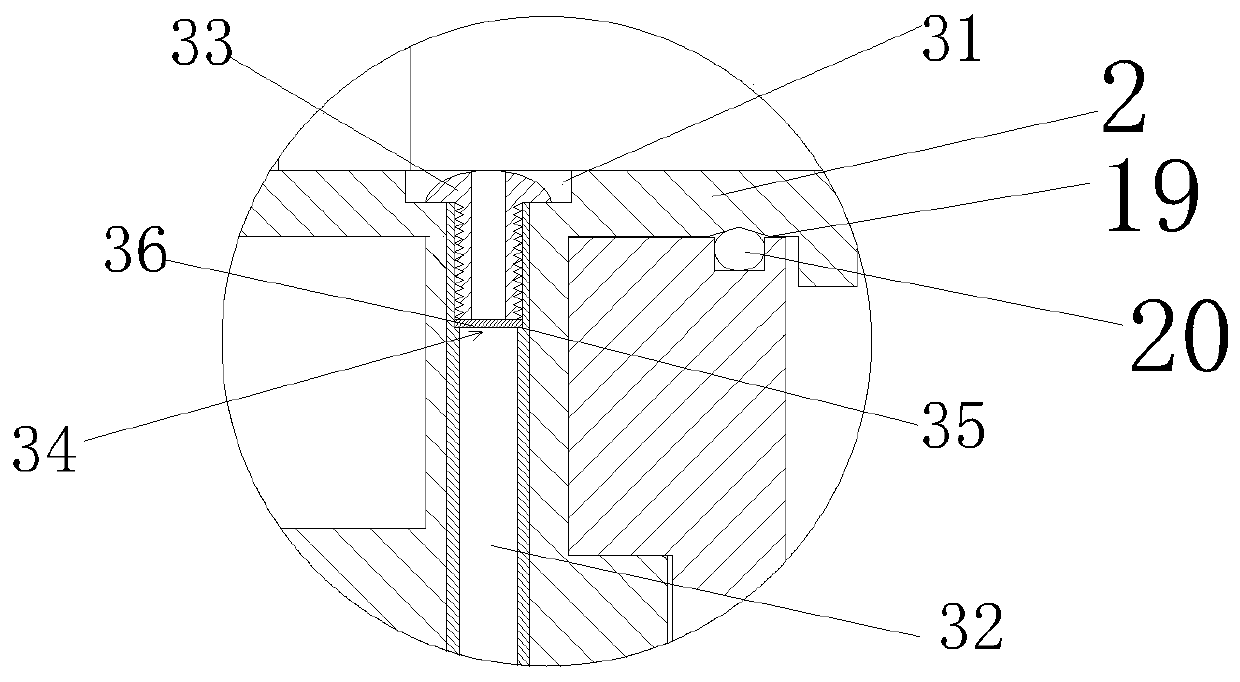

[0026] Such as Figure 1-5As shown, an anti-explosion container with a shielding and anti-theft function includes a cylinder body 1, a cover plate 2, and an explosion-proof cover. The connecting ring 3 is sleeved in the cylinder body 1 and is detachably and fixedly connected with the cylinder body 1 , and the detachable and fixed connection is realized between the outer surface of the connecting ring 3 and the inner surface of the cylinder body 1 by fixedly setting latches 4 . The connecting ring 3 is provided with a pin hole 5 that runs through the inner and outer sides of the connecting ring 3, and a conductive sleeve 6 with a circular structure is fixed in the plug hole 5, and the conductive sleeve 6 is made of copper material. The outer wall of the conductive sleeve 6 is attached to the inner wall of the pin hole 5, and the inner end of the conductive sleeve 6 is a trumpet-shaped structure that gradually expands outward. plate 7, the connection between the inner surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com