Partition wall ground levelling mounting structure for fabricated light steel keel

A light steel keel and installation structure technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of light steel keel partition wall construction restrictions and influence on construction progress, so as to overcome irreversibility, improve decoration efficiency, and facilitate construction. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

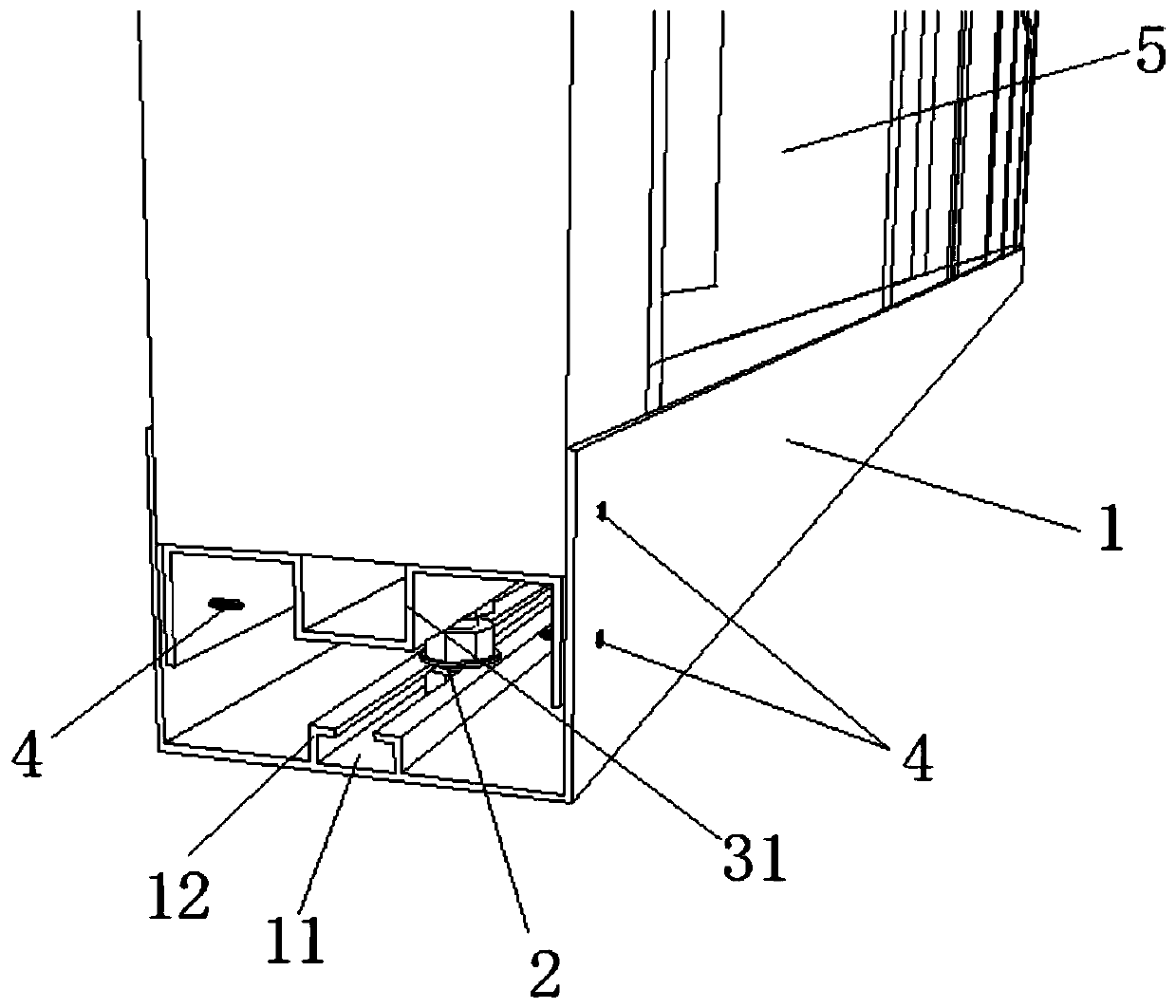

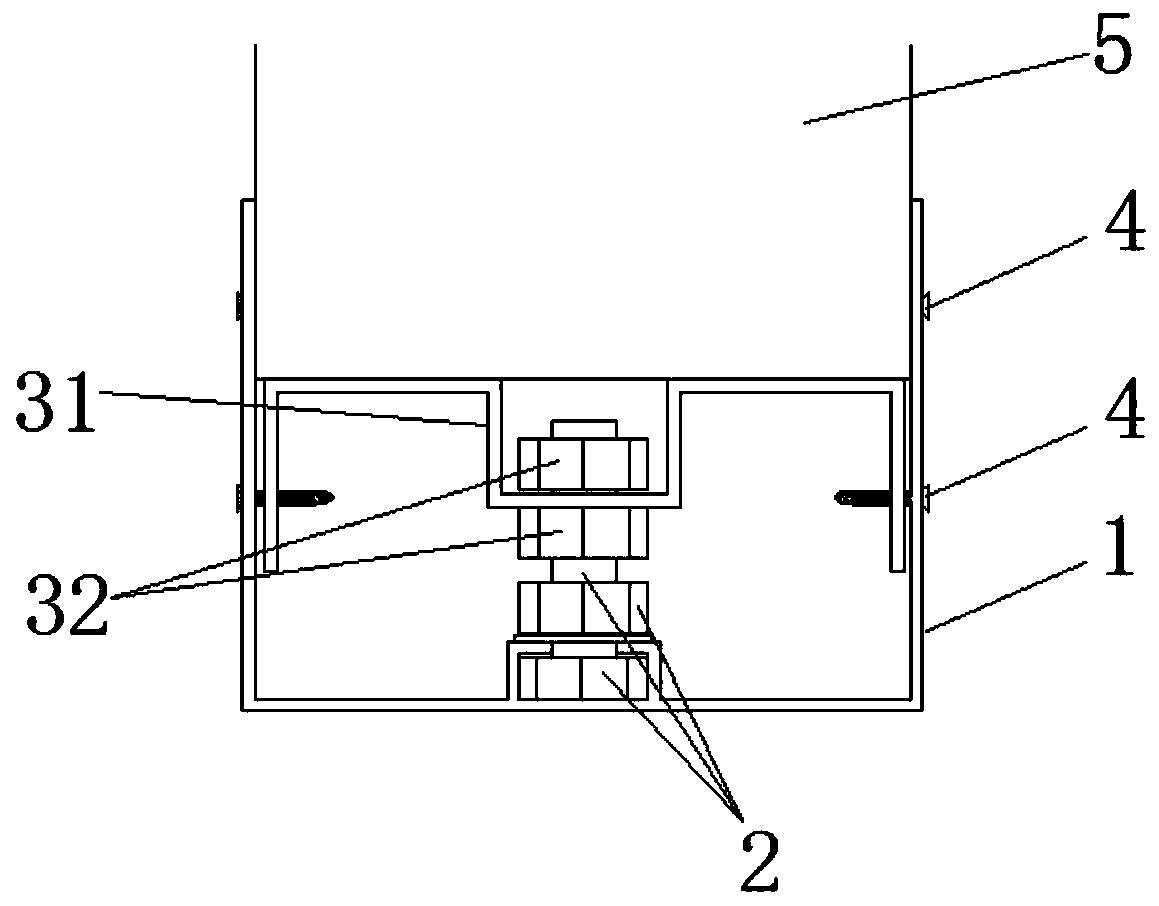

[0037] see Figure 1 to Figure 2 , the figure shows a prefabricated light steel keel partition wall ground leveling installation structure provided by Embodiment 1 of the present invention, which includes: a keel 1, a connecting groove 11 is provided on the inner bottom of the keel, and the connecting groove 11 is along the keel 1. It is arranged in the length direction and runs through the keel 1; the connecting piece 2 is arranged perpendicular to the connecting surface of the keel 1, and its bottom is snapped into the connecting groove 11; Above the keel 1 , the intermediate position of the bearing frame 31 passes through the connecting piece 2 , and the adjusting piece 32 is sheathed on the connecting piece 2 and located on the upper and lower sides of the bearing frame 31 . Wherein, the adjusting member 32 is an adjusting nut.

[0038] The partition wall ground leveling installation structure of an assembled light steel keel provided in this embodiment mainly includes a ...

Embodiment 2

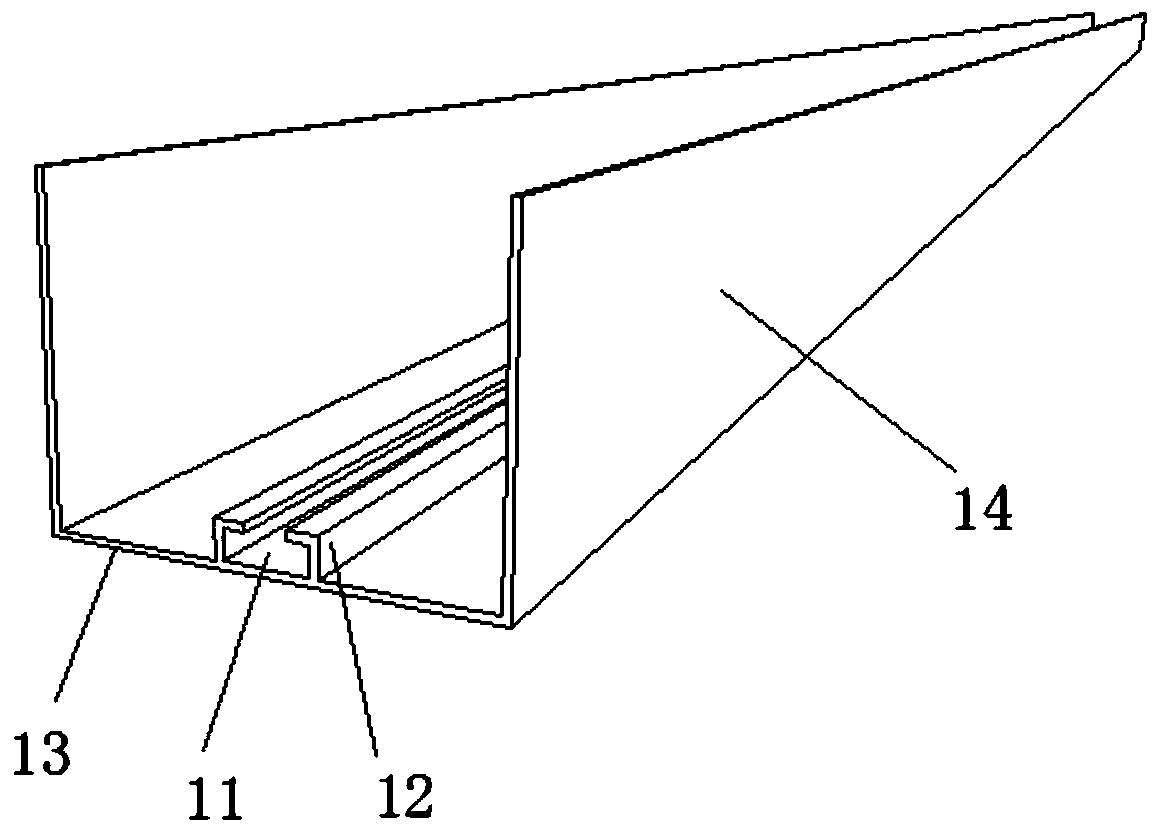

[0046] see Figure 3 to Figure 4 , the figure shows a prefabricated light steel keel partition wall ground leveling installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improved technologies Solution: the connection groove 11 includes symmetrically arranged "┏"-shaped clamping plates 12. Through the setting of the above structure, the position of the connecting piece 2 in the connecting groove 11 can be changed arbitrarily, and the distance between the two connecting pieces 2 can be adjusted according to actual needs, and the adjustment is more flexible.

Embodiment 3

[0048] see Figure 5 to Figure 6, the figure shows a prefabricated light steel keel partition wall ground leveling installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following improved technologies Solution: the connecting piece 2 includes a connecting head 21 and a connecting rod 22, the connecting head 21 is engaged with the connecting groove 11, and the connecting rod 22 is adjusted to connect the carrier frame 31; the connecting piece 2 also includes a fastening screw 23, which is sleeved At the bottom of the connecting rod 22 and above the connecting groove 11 . Wherein, the connecting rod 22 is an adjusting screw. Through the setting of the above structure, the connecting head 21 of the connector 2 is clamped with the connecting groove 11, the connecting rod 22 protrudes from the connecting groove 11, and the bottom is tightened and fixed by the fastening screw 23; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com