Experimental device for service reliability of composite blades under shock, vibration and high temperature excitation

An experimental device and reliable technology, applied in the field of impact dynamics, can solve the problems of material performance influence, failure to consider machine mechanics, and failure to consider the thermal environment of the test piece, etc., to achieve the effect of real and reliable experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

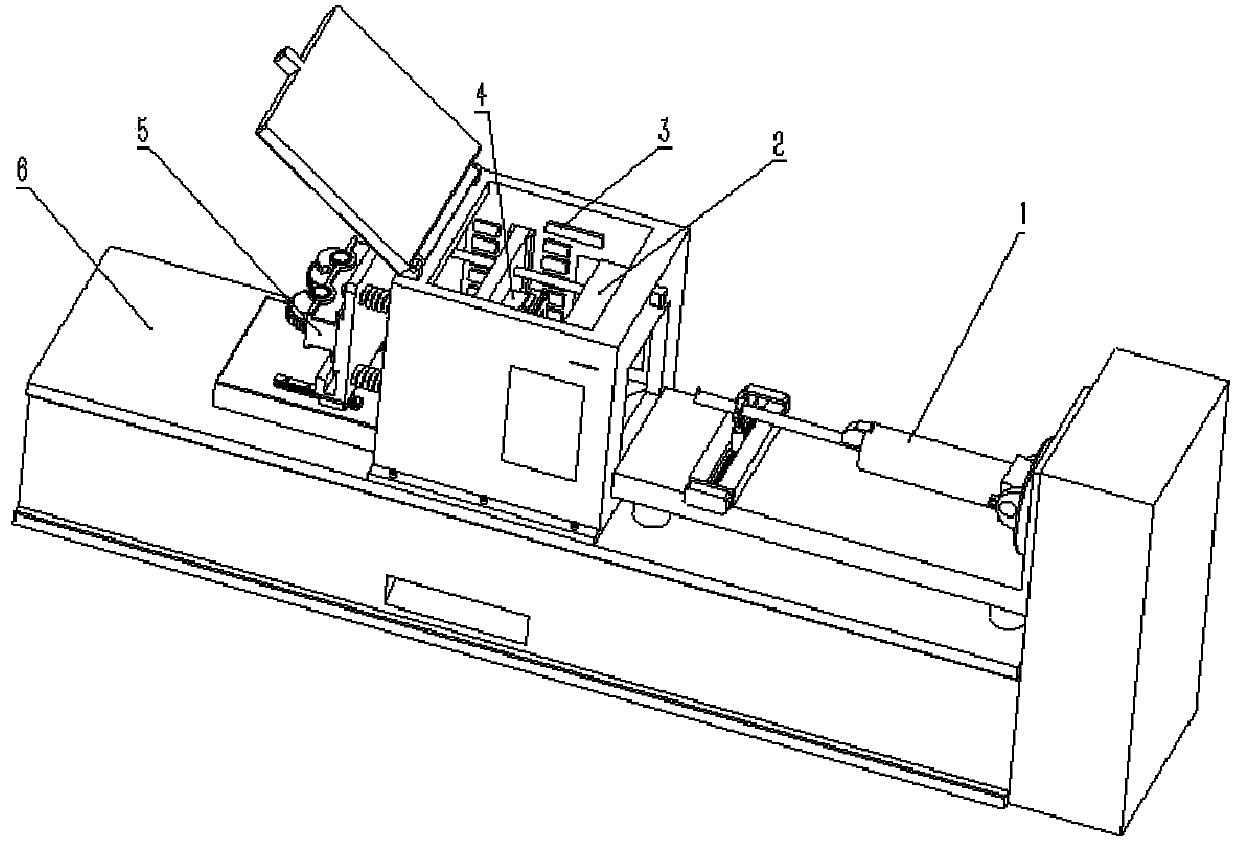

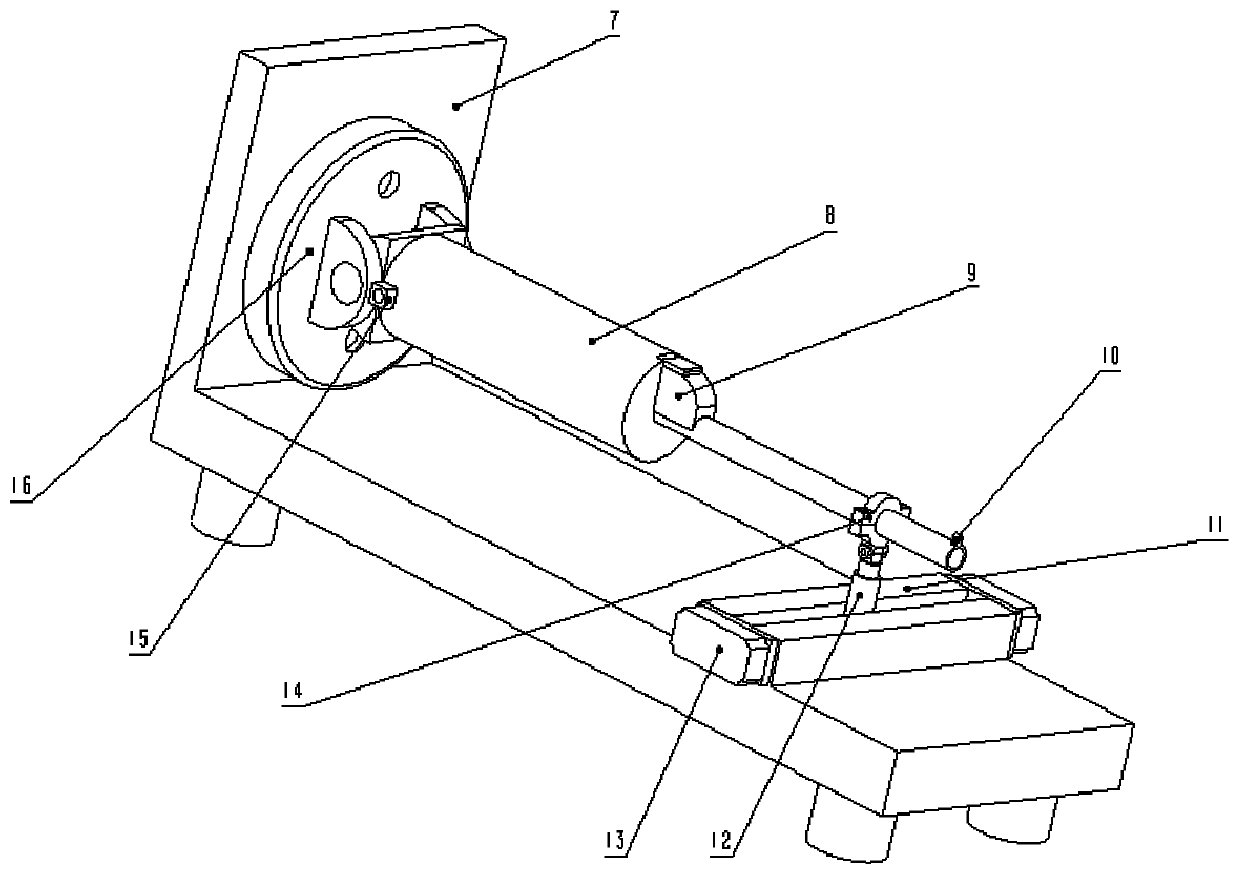

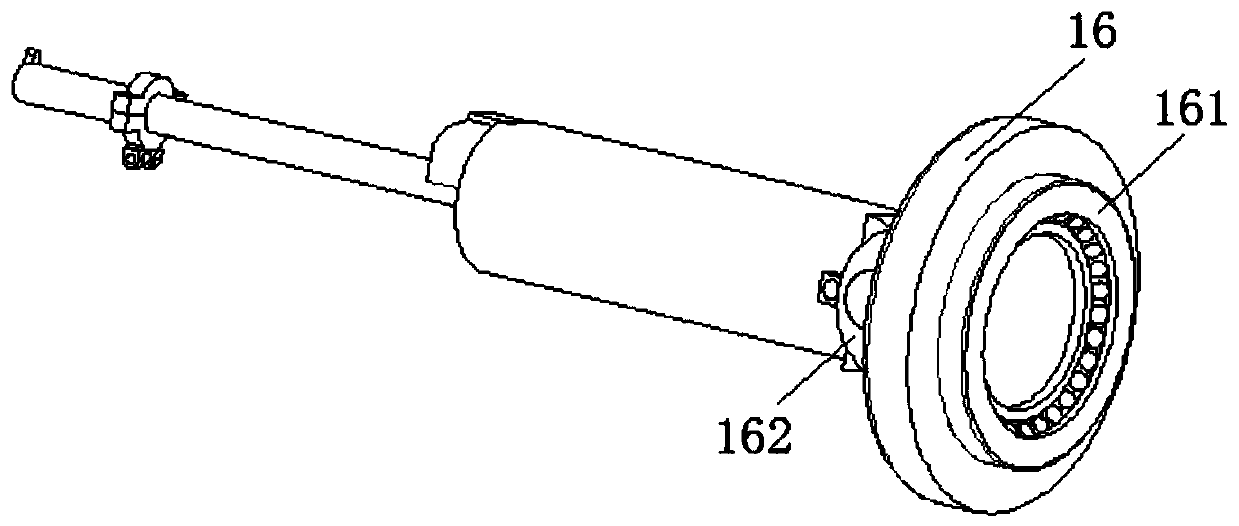

[0034] Such as figure 1 As shown, the composite blade service reliability test device of the present invention under shock, vibration, and high temperature excitation includes: a power supply module, a measurement module, an adjustable angle impact module 1, a clamping module 2, a thermal environment module 3, and a projectile recovery module 4. Basic excitation module 5 and platform module 6. The clamping module 2 is set in the thermal environment module 3, and is used to clamp and fix the blade test piece to be tested; the adjustable angle impact module 1 is set on the platform module 6, and is used to launch projectiles to impact the blade test piece; The power supply module is used to provide power to the adjustable angle impact module 1 to launch projectiles; the projectile recovery module 4 is placed in the thermal enviro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com