Inertial piezoelectric exciting device and implementation method

A piezoelectric excitation and inertia technology, applied in the direction of the fluid using vibration, can solve the problems of low upper limit frequency, heavy weight, magnetic flux leakage, etc., achieve the effect of reducing volume and weight, and eliminating installation and fixing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

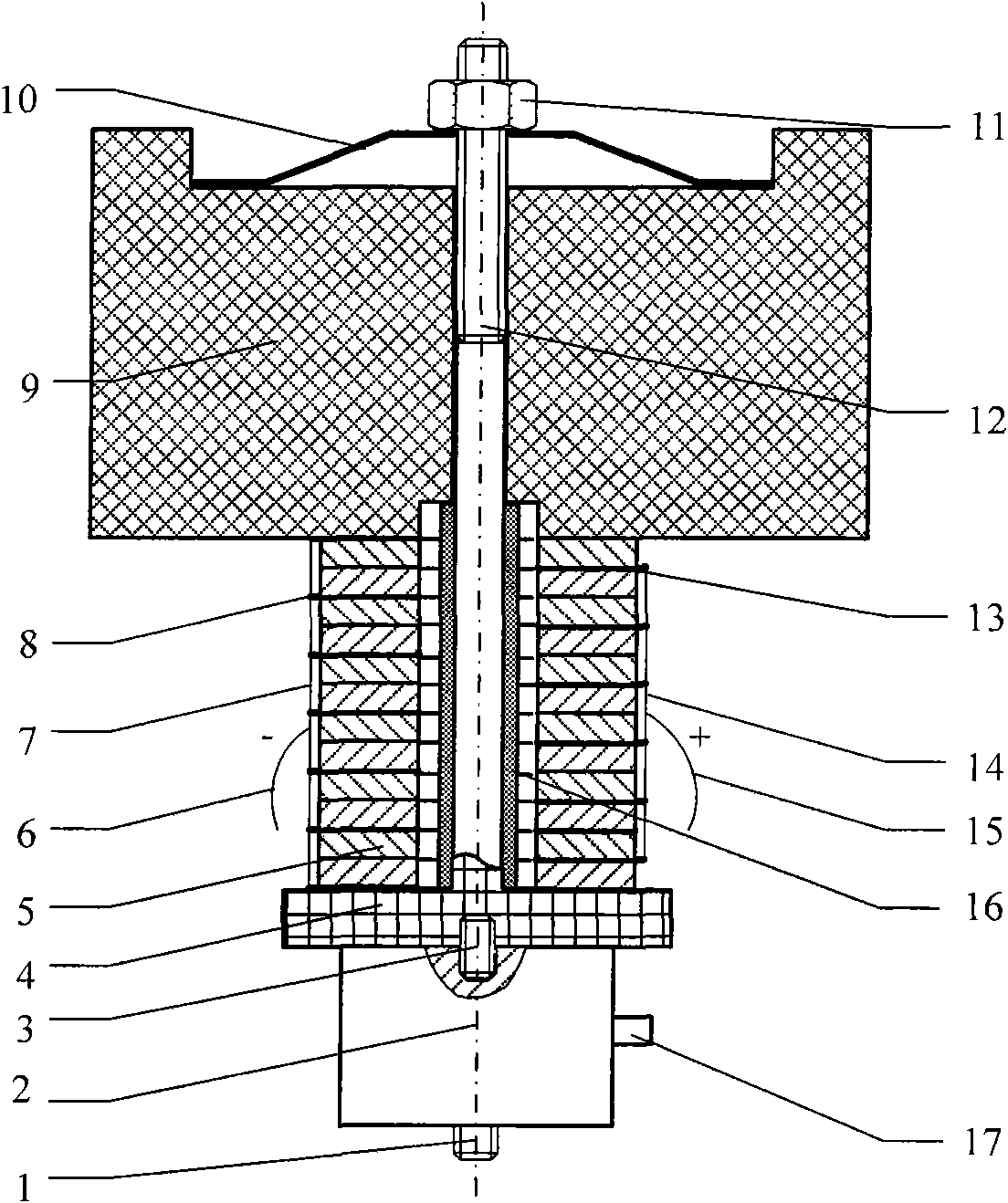

[0014] The present invention is described in detail below in conjunction with accompanying drawing description:

[0015] Such as figure 1 As shown, one end of the piezoelectric ceramic stack 5 is connected to the inertial mass 9, and the other end is connected to the base 4, and each joint surface is pressed by the pre-tightening bolt 12 and the pre-tightening spring 10 in the center, and the joint surface can be bonded , it is also possible to realize the tight connection of the joint surface only through the pre-tension mechanism without bonding. The adjustment of the pre-tension force can be carried out by adjusting the pre-tension nut 11. The pre-tension spring 10 adopts a disc spring with high stiffness. The inner diameters of the bosses on the top surface of the inertial mass 9 are equal, and the large diameter side of the pretension spring 10 is connected to the top surface of the inertial mass 9, and the other side with a smaller diameter is connected to the pretension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com