Optical imaging lens

An optical imaging lens and lens technology, applied in optics, optical components, lenses, etc., to achieve high imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

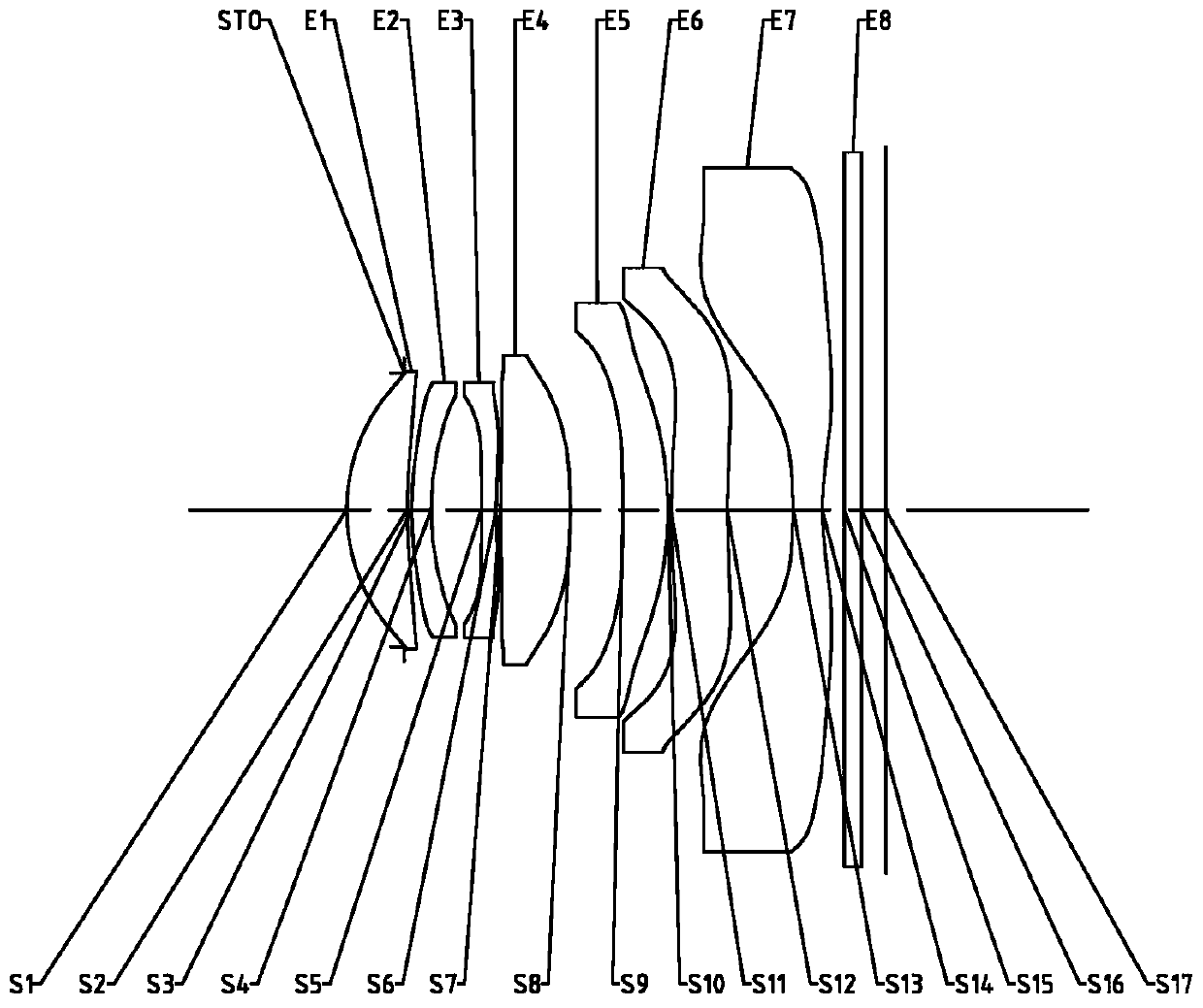

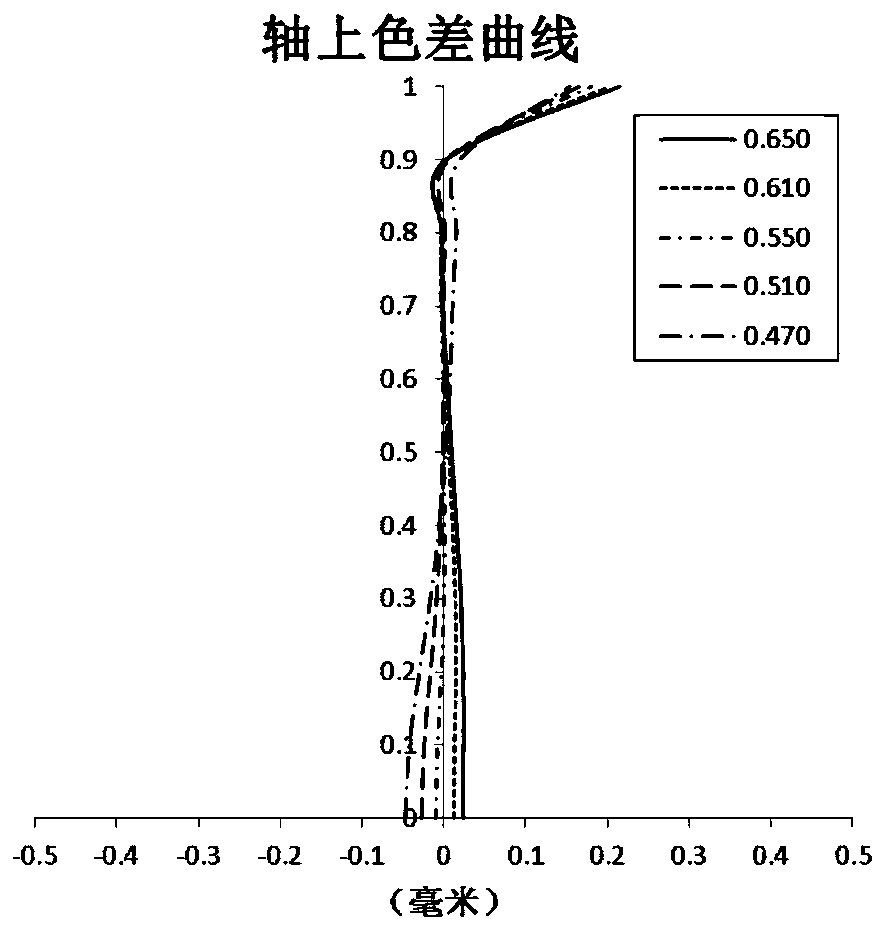

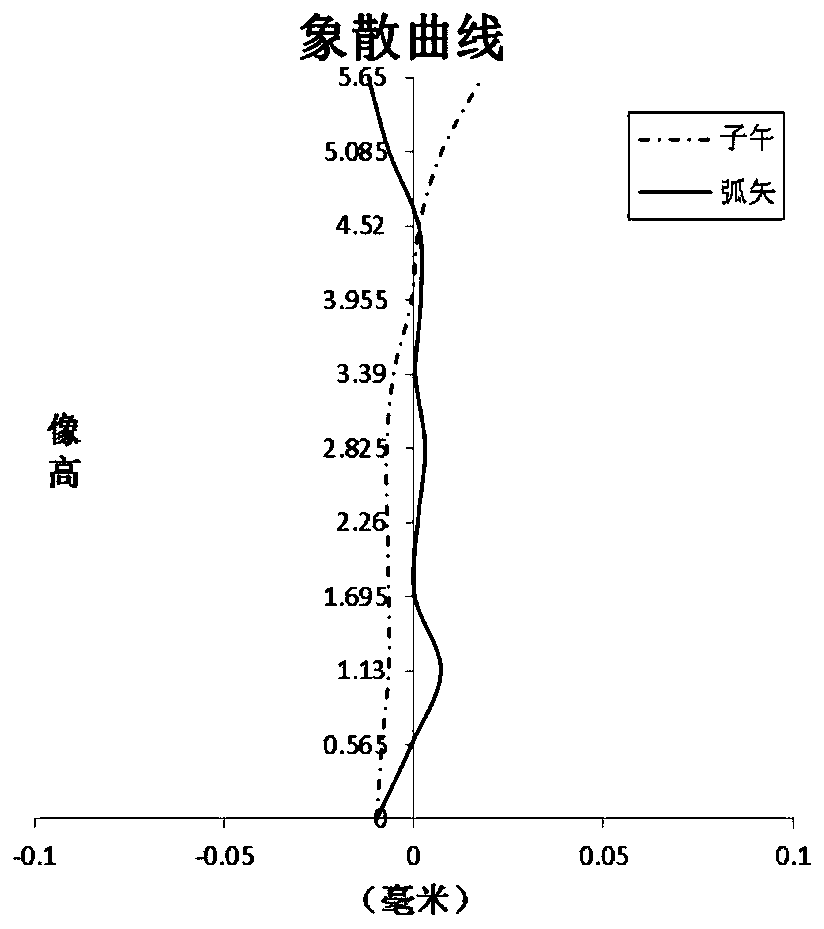

[0061] Refer to the following Figure 1 to Figure 2C An optical imaging lens according to Embodiment 1 of the present application is described. figure 1 A schematic structural diagram of an optical imaging lens according to Embodiment 1 of the present application is shown.

[0062] Such as figure 1 As shown, the optical imaging lens includes sequentially from the object side to the image side along the optical axis: a stop STO, a first lens E1, a second lens E2, a third lens E3, a fourth lens E4, a fifth lens E5, a sixth lens Lens E6, seventh lens E7, filter E8 and imaging surface S17.

[0063] The first lens E1 has positive refractive power, its object side S1 is convex, and the image side S2 is concave; the second lens E2 has positive refractive power, its object side S3 is convex, and the image side S4 is concave; the third lens E3 has a negative Refractive power, the object side S5 is convex, and the image side S6 is concave; the fourth lens E4 has positive refraction, ...

Embodiment 2

[0076] Refer to the following Figure 3 to Figure 4C An imaging lens according to Embodiment 2 of the present application is described. In this embodiment and the following embodiments, for the sake of brevity, descriptions similar to those in Embodiment 1 will be omitted. image 3 A schematic structural diagram of an optical imaging lens according to Embodiment 2 of the present application is shown.

[0077] Such as image 3 As shown, the optical imaging lens includes sequentially from the object side to the image side along the optical axis: a stop STO, a first lens E1, a second lens E2, a third lens E3, a fourth lens E4, a fifth lens E5, a sixth lens Lens E6, seventh lens E7, filter E8 and imaging surface S17.

[0078] The first lens E1 has positive refractive power, its object side S1 is convex, and the image side S2 is concave; the second lens E2 has positive refractive power, its object side S3 is convex, and the image side S4 is concave; the third lens E3 has a negat...

Embodiment 3

[0088] Refer to the following Figure 5 to Figure 6C An optical imaging lens according to Embodiment 3 of the present application is described. Figure 5 A schematic structural diagram of an optical imaging lens according to Embodiment 3 of the present application is shown.

[0089] Such as Figure 5 As shown, the optical imaging lens includes sequentially from the object side to the image side along the optical axis: a stop STO, a first lens E1, a second lens E2, a third lens E3, a fourth lens E4, a fifth lens E5, a sixth lens Lens E6, seventh lens E7, filter E8 and imaging surface S17.

[0090] The first lens E1 has positive refractive power, its object side S1 is convex, and its image side S2 is concave; the second lens E2 has negative refractive power, its object side S3 is convex, and its image side S4 is concave; the third lens E3 has Negative refractive power, the object side S5 is convex, and the image side S6 is concave; the fourth lens E4 has positive refractive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com