Method for laying cable in pipeline

A cable laying and pipeline technology, which is applied in the direction of cable laying equipment, cable installation, cable installation device, etc., can solve the problems of cable weight offset, cable wear, cable contact with pipeline, etc., and achieve the effect of ensuring safe laying and convenient carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

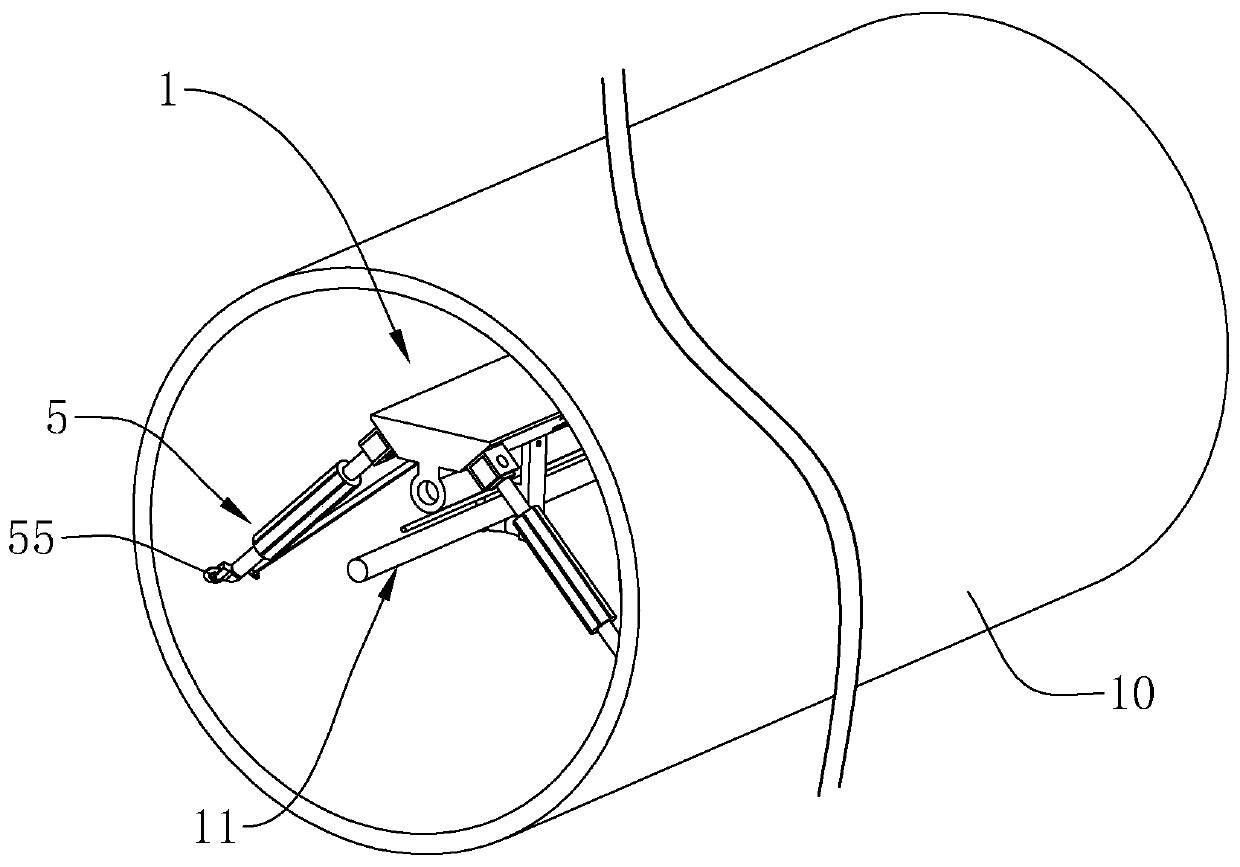

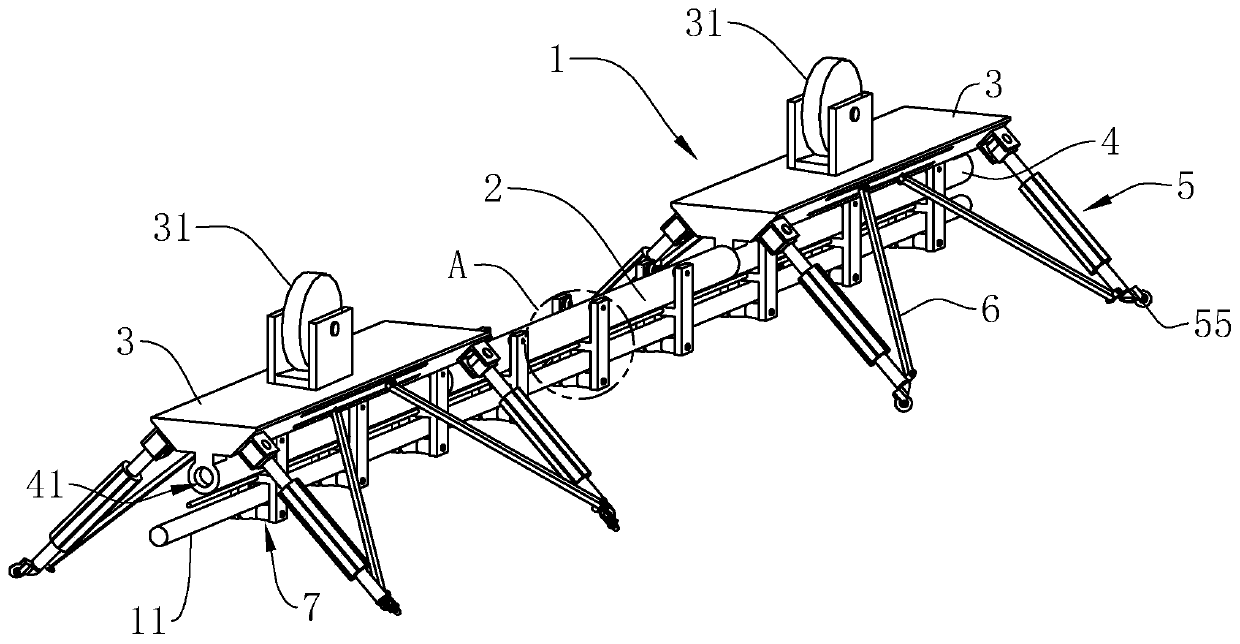

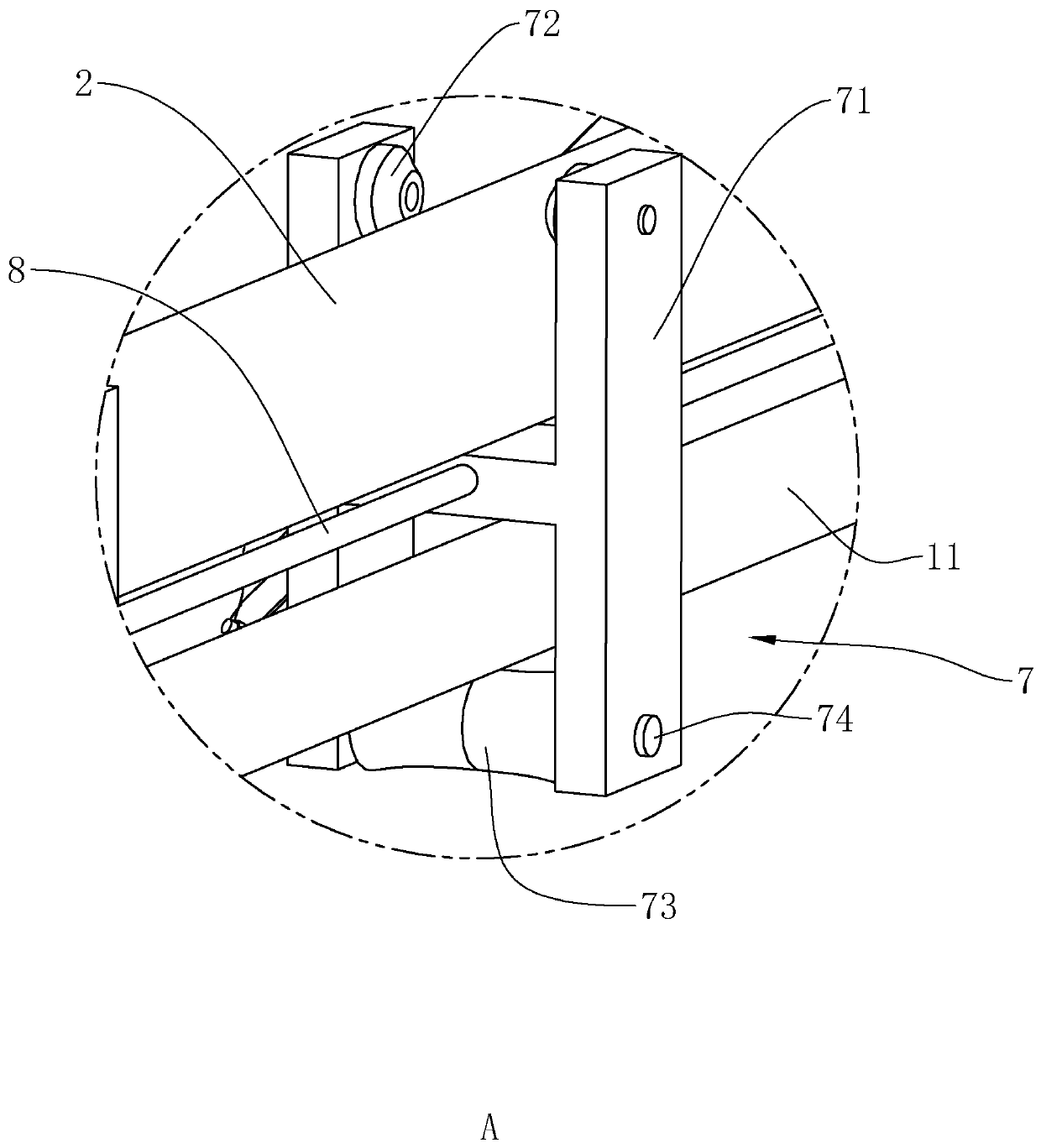

[0037] refer to figure 1 with figure 2 , is a method for laying cables in pipelines disclosed by the present invention, comprising a support frame 1, there are multiple support frames 1, connecting rods 2 are arranged between two adjacent support frames 1, and the support frame 1 includes a base 3, a circular The track 4 and the supporting legs 5, the base 3 are elongated, and the two sides of the base 3 are respectively provided with two supporting legs 5, and the included angle between the supporting legs 5 on both sides is an obtuse angle, which is selected as 120 degrees; The angle between the legs 5 is downward, when the support frame 1 is placed in the pipeline 10, the lower ends of the two legs 5 are provided with support wheels 55, the support wheels 55 are supported on the inner wall of the pipeline 10, and the support wheels 55 It is a universal wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com