Multi-pass and multi-directional rotary rolling forming method for large horizontal and high-rib thin-walled rings

A thin-walled ring and multi-pass technology, applied in the field of precision rolling forming, can solve the problems of limited external dimensions and difficulty in forming large horizontal and high-rib thin-walled rings, so as to reduce the forming force, improve the internal structure and mechanical properties, and size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

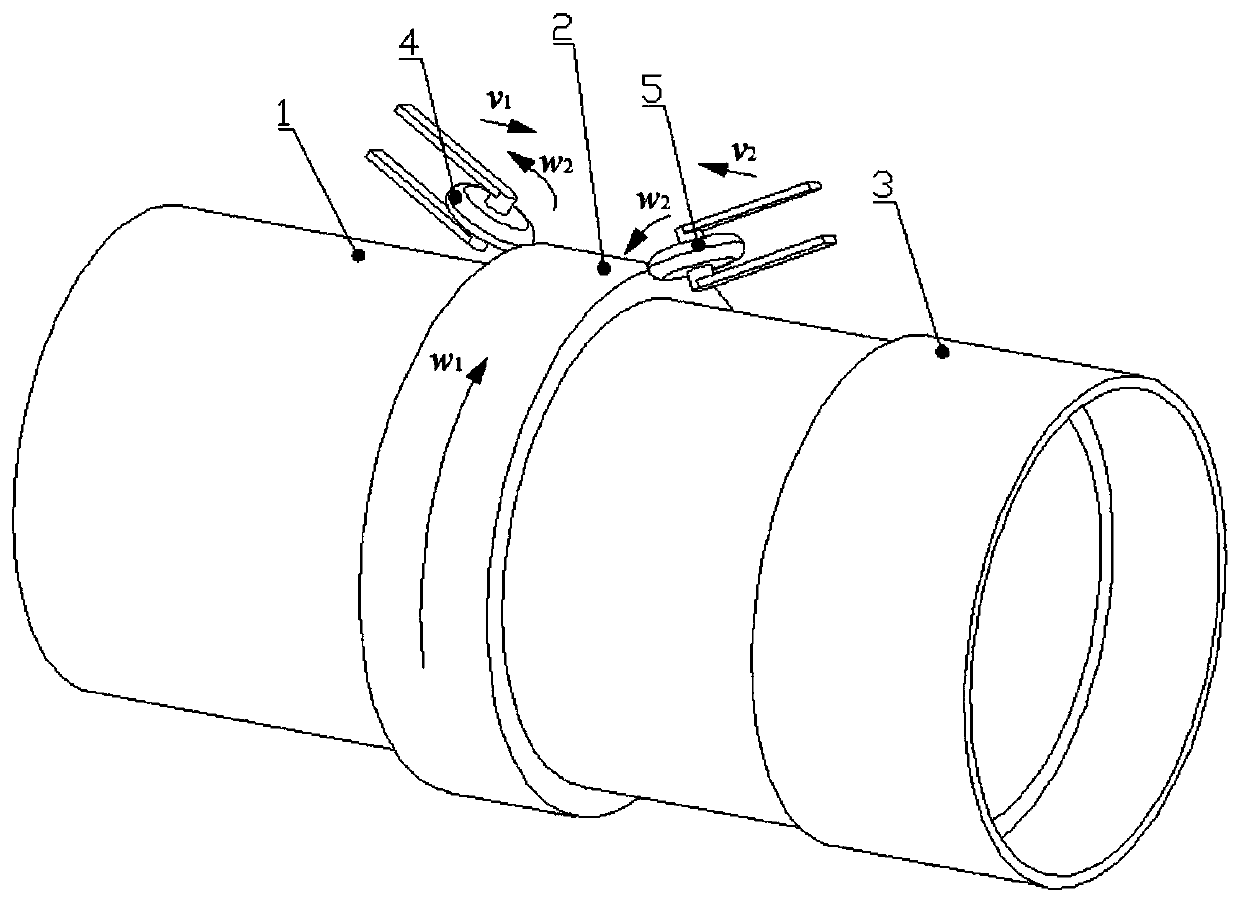

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0033] Such as Figure 1-Figure 7 As shown, the precision roll-forming method of the large horizontal high rib thin-walled ring of the present invention comprises the following steps:

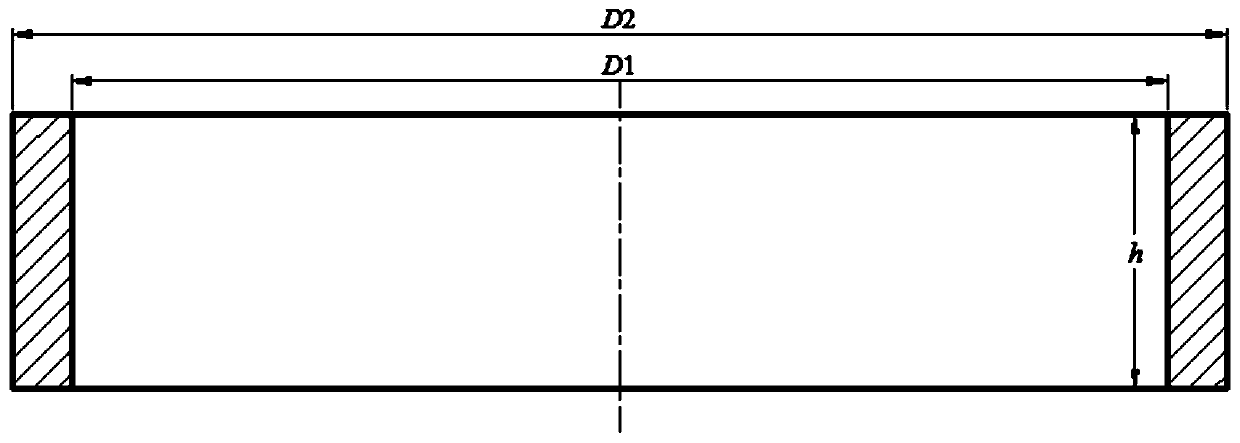

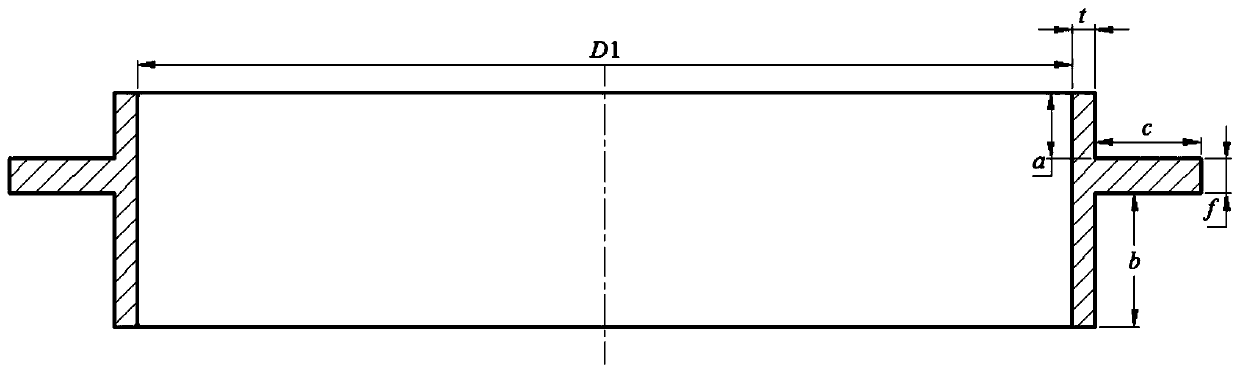

[0034] S1, obtain the ring blank 2, the blank 2 is a ring with a rectangular cross-section, which can be produced by upsetting, casting, punching, punching, extrusion, flat end face and turning. The parts made by the method of the present invention are large thin-walled rings 8 with horizontal and high ribs. Such as figure 1 , 2 As shown, the height of blank 2 is h, and the inner diameter of blank 2 is D 1 , the outer diameter of blank 2 Among them, the inner diameter of the large horizontal high rib thin-walled ring is D 1 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com