A rack precision forming method by cold rotary rolling

A technology of precision forming and cold oscillating rolling, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., to achieve the effects of reducing production costs, large strain strengthening, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

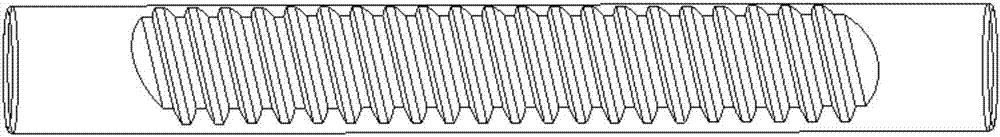

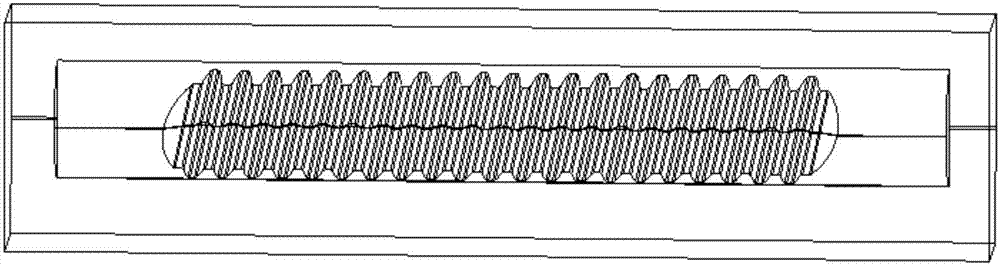

[0054] Such as figure 1 , the rack is left-handed, m=2mm, z=20, α=20°, β=12°, h a = 1.7 mm, h f = 2.1 mm, h 1 =8.59mm, δ=12°, H=15mm, d=25mm, L=192mm, upper die swing angle γ=1°, upper die rotation interval angle ε=0.01.

[0055] (1) The blank is designed as a long cylindrical rod whose diameter and length are equal to the diameter and length of the rack respectively.

[0056] (2) The tooth shape of the rack is formed by swinging the upper die (swing head) of the cold swing roller, and the back of the tooth shape is formed by the lower die. The entire rack only needs to be cold-rolled to form the tooth-shaped part, and the rest does not need to be formed.

[0057] (3) The upper mold of the cold swing rolling adopts a straight line trajectory, which is perpendicular to the axis of the cylindrical blank, that is, the upper mold of the cold swing rolling swings along the radial direction of the blank.

[0058] (4) The upper mold of the cold swing rolling is a pyramid, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com