Steel ladle structure for small-pit-distance covered hot repair

A technology of ladle and pit distance, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problem that is not conducive to ensuring the personal safety of hot repair personnel, steel ladle with cover cannot be repaired normally, and the pit mouth space is not enough. Cover opening and other problems, to achieve the effect of observing refractory materials and slag dumping at the bottom of the ladle, avoiding temperature loss in the ladle, and realizing the cleaning of steel slag in the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

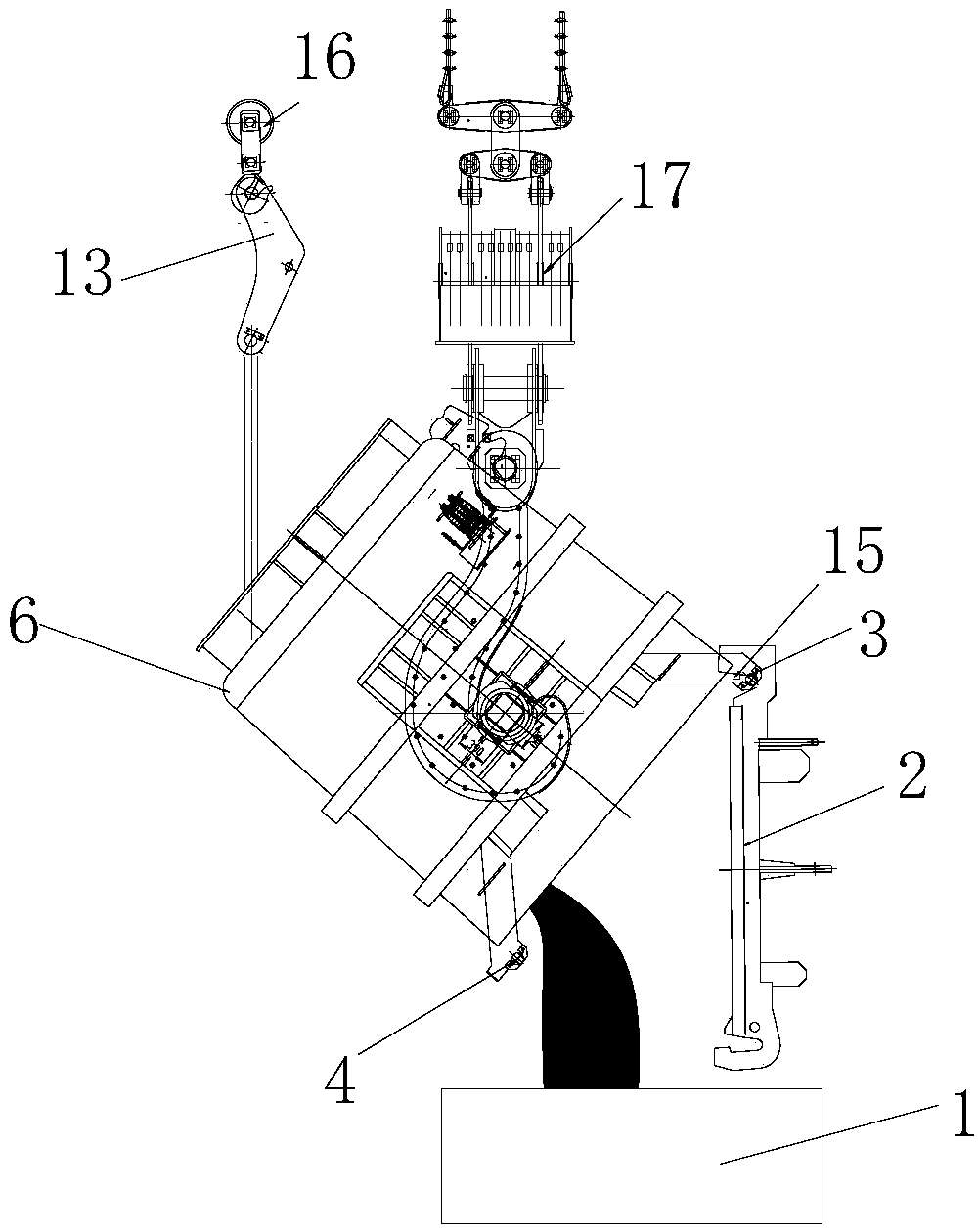

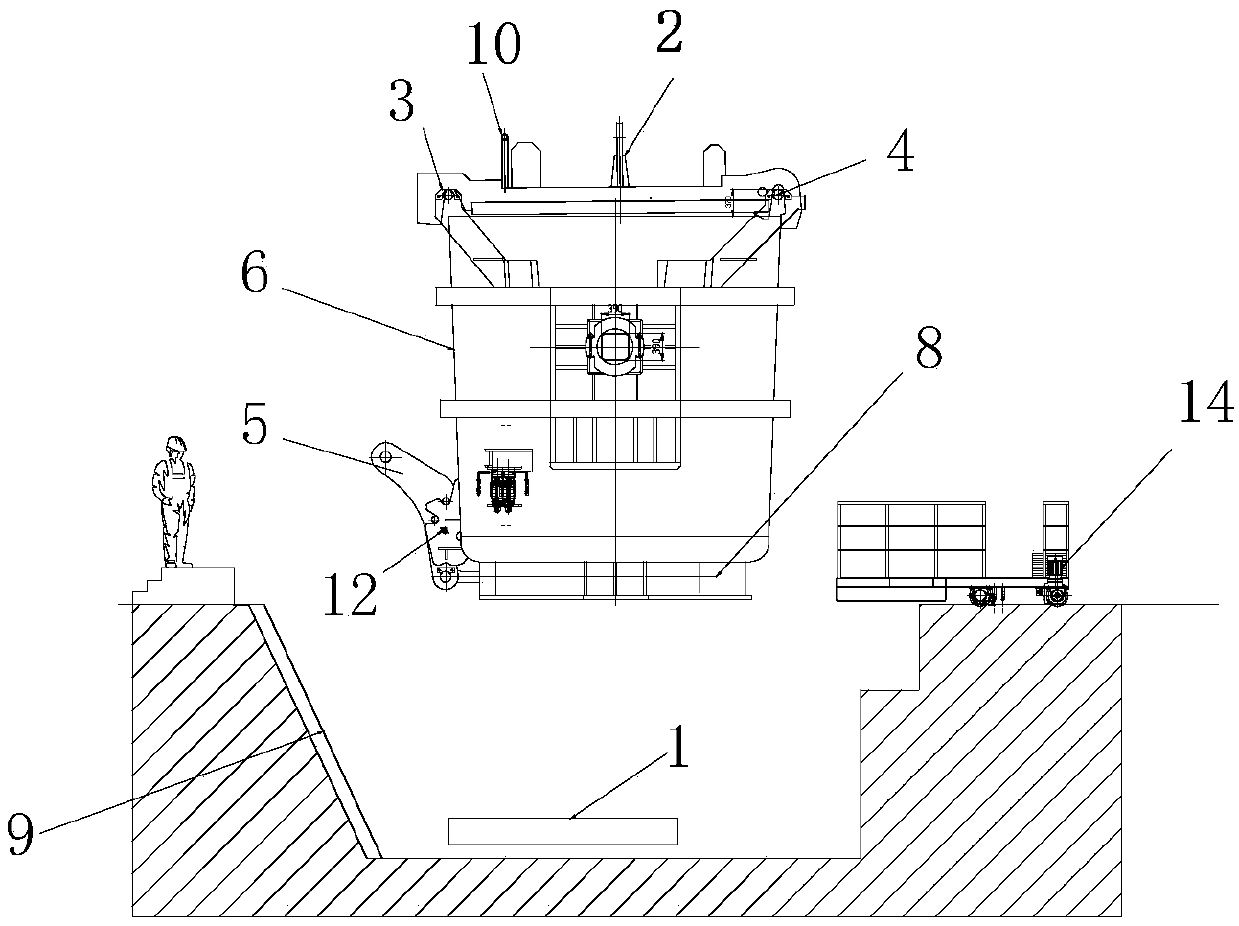

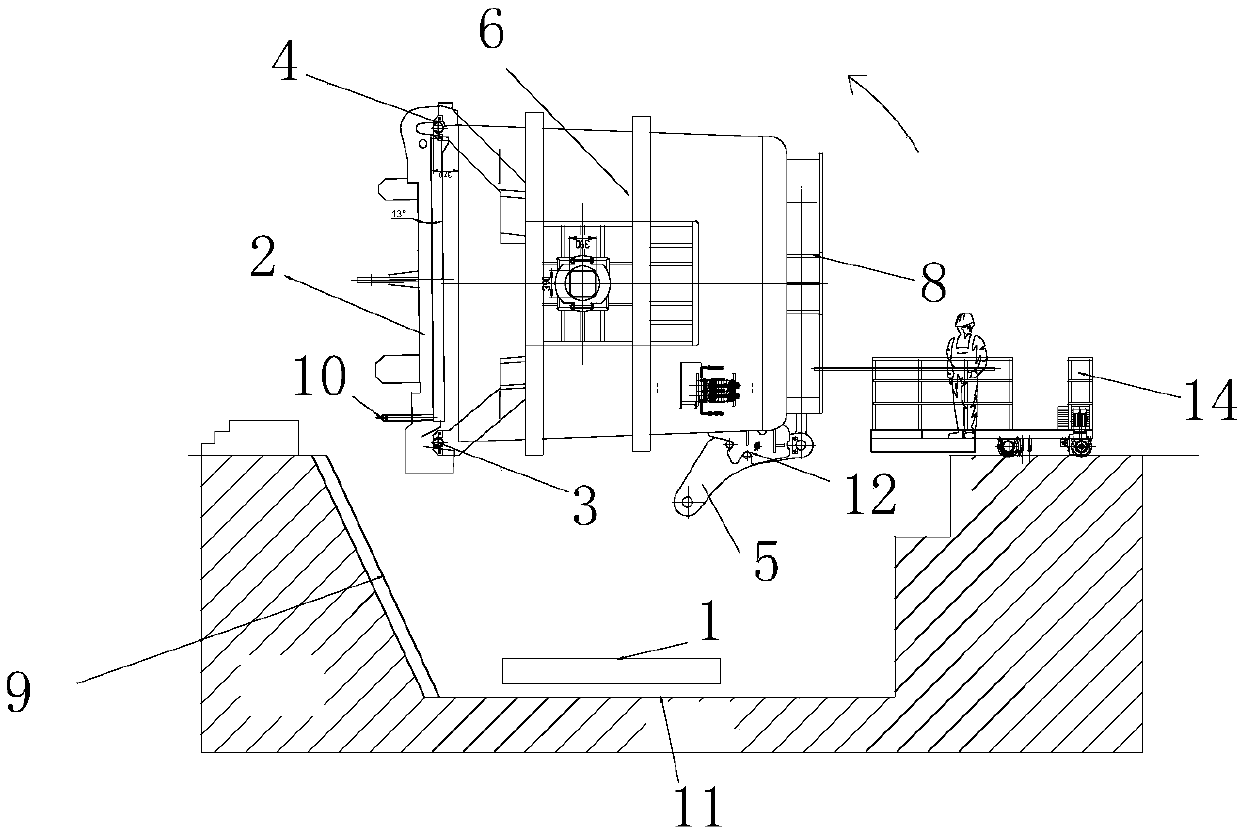

[0022] Such as Figure 1-4 As shown, the ladle structure used for the hot repair of small pits with covers in this embodiment includes a ladle body 6 and a ladle cover 2, the ladle body 6 is provided with a tipping hook 13, and the ladle body 6 is arranged on the ladle Tipping inside the hot repair pit 11 and driven to rotate by the ladle tipping table 8, the ladle body 6 rotates to the right to remove slag, and the ladle body 6 rotates to the left for hot repair, that is, the hot repair rotation direction of the ladle body 6 The direction of rotation is opposite to that of slag dumping; the opening of the ladle body 6 is provided with a left hinge shaft 3 and a right hinge shaft 4, and the ladle cover 2 is provided with a left hook that cooperates with the left hinge shaft 3 and the right hinge shaft 4 respectively 5. Right hook 7.

[0023] Preferably, in this embodiment, the left hinge shaft 3 and the right hinge shaft 4 are in two groups, and correspondingly, there are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com