Repetitive on-orbit locking mechanism

A rail locking and unlocking technology, which is used in motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of complicated loading procedures and difficult to meet repeated loading on orbit, and achieves large unlocking force margin and high locking rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

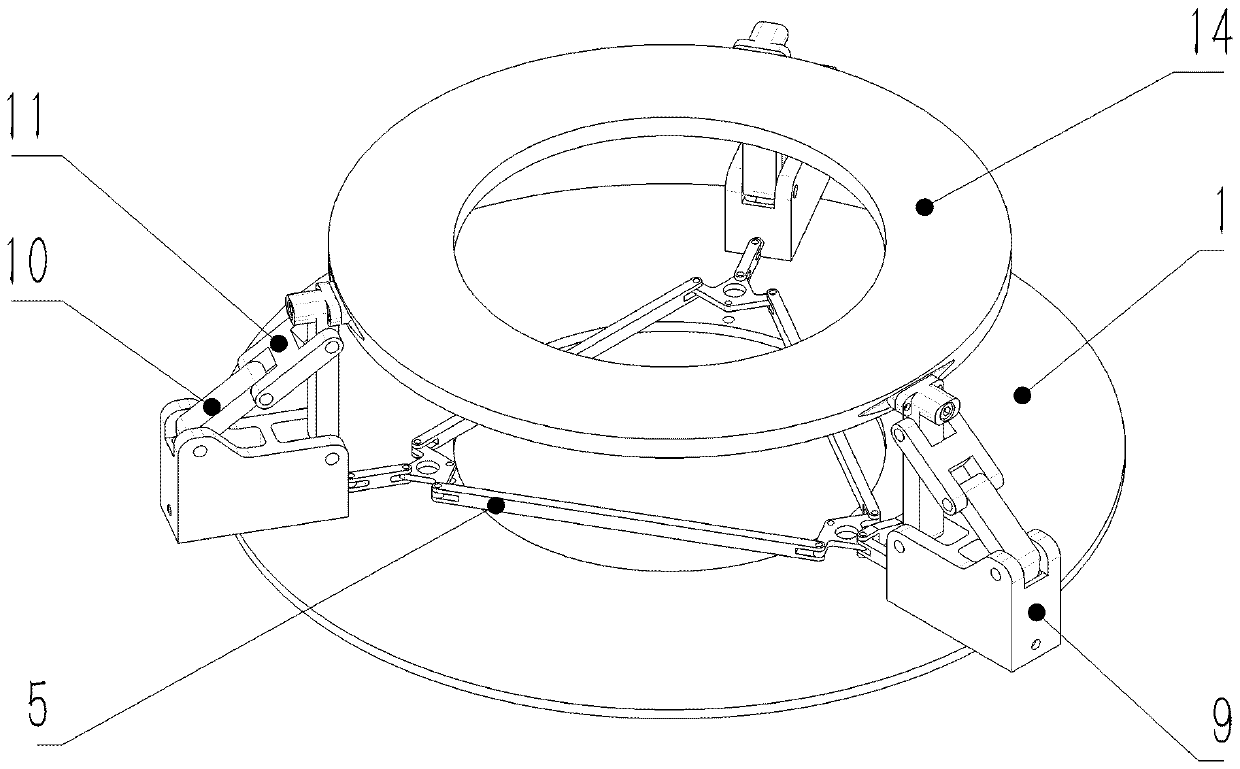

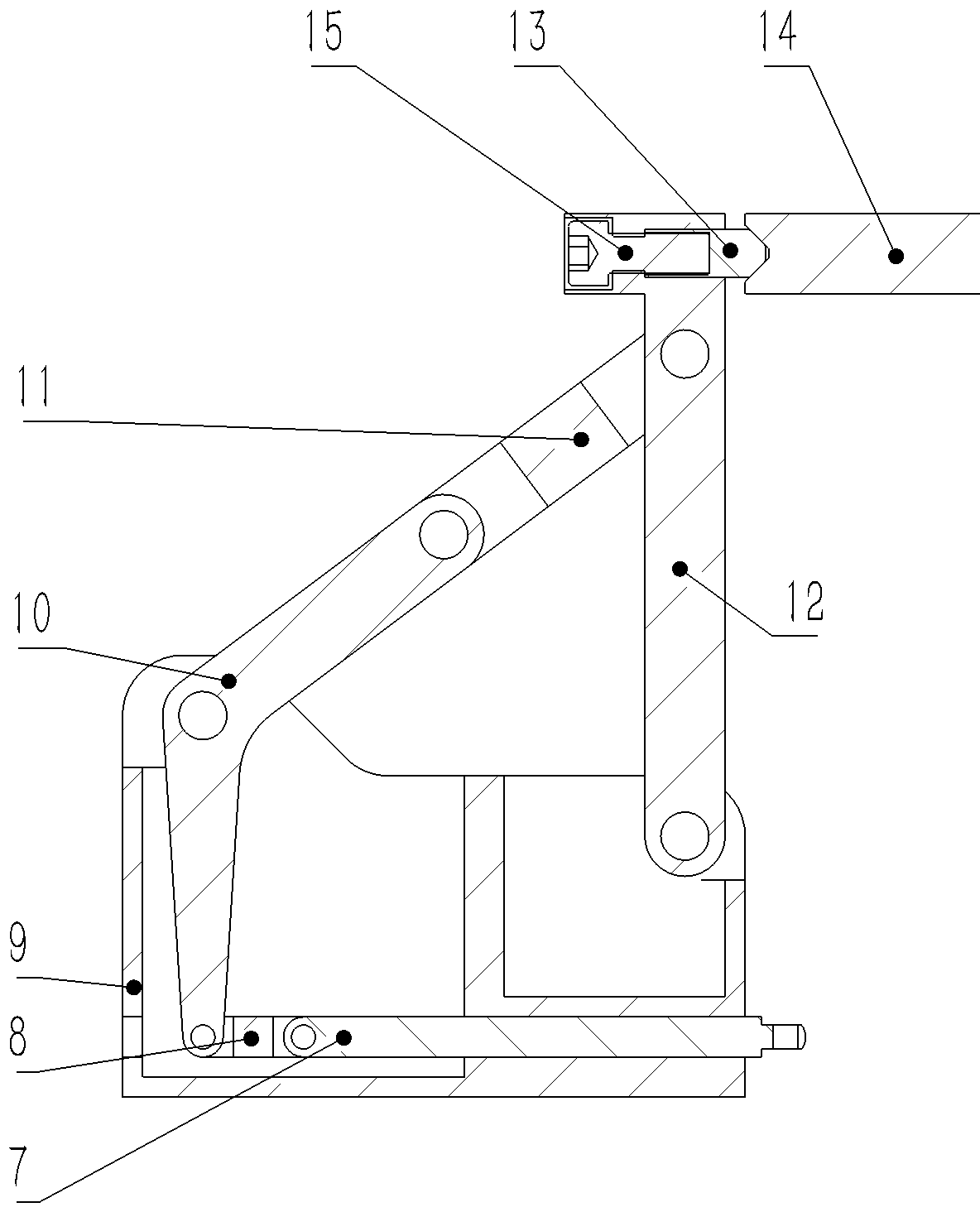

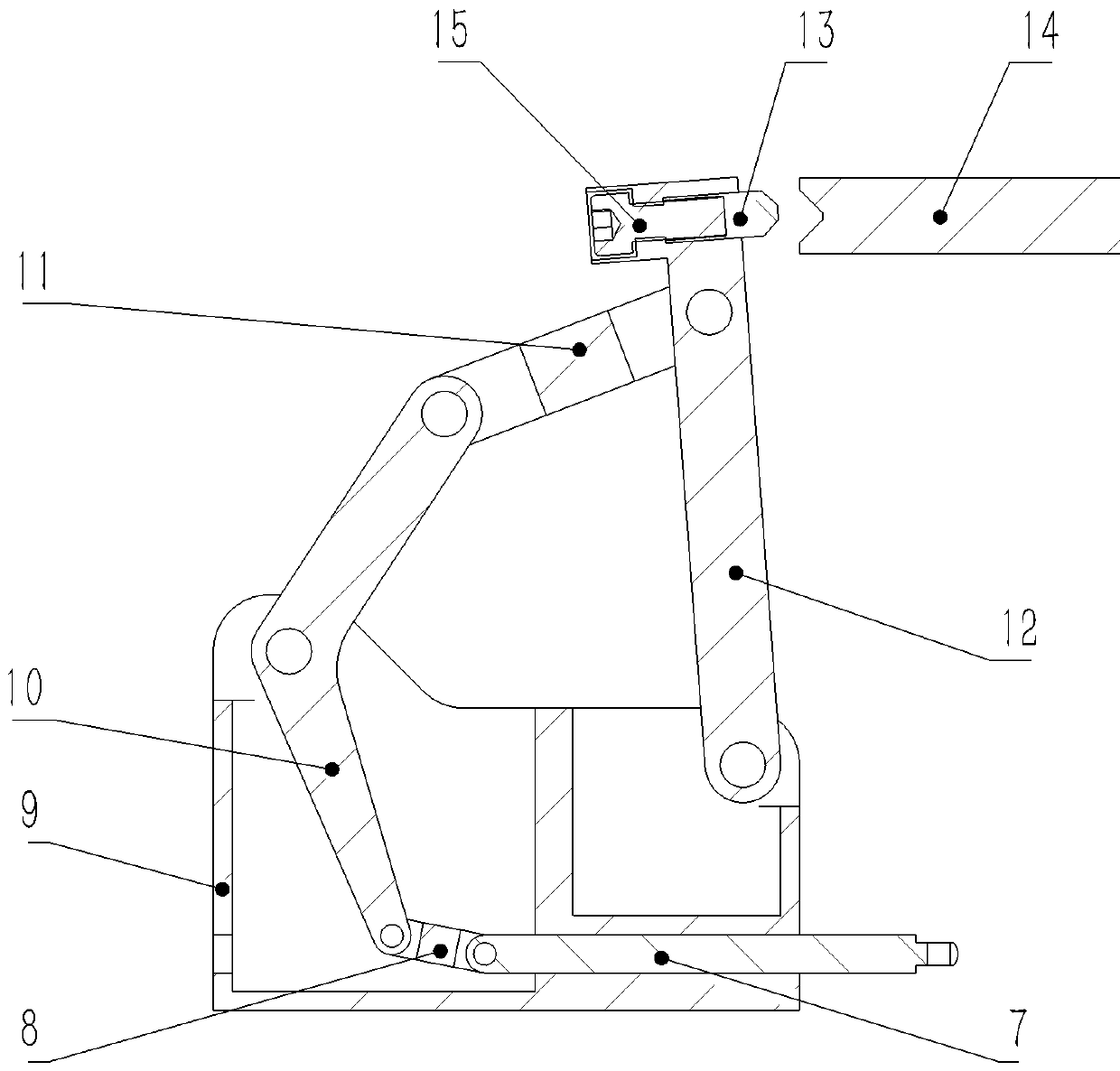

[0030] Such as figure 1 , 2 , 3, 4, and 5, a repetitive on-track locking mechanism is characterized in that a base 1, a turntable 2, a drive link 3, an L-shaped link 4, a synchronous link 5, an unlock link A6, an unlock Connecting rod B7, unlocking connecting rod C8, support seat 9, supporting connecting rod A10, supporting connecting rod B11, pressing connecting rod 12, pressing block 13, pressing flange 14, pressing screw 15;

[0031] The base 1 is a plate-shaped metal part, provided with a mounting flange, screw holes and hinge holes;

[0032] The turntable 2 is a plate-shaped metal piece, and a through hole is respectively provided at the center and the eccentric position;

[0033] The driving connecting rod 3 is a rod-shaped metal piece with hinged holes at both ends;

[0034] The L-shaped connecting rod 4 is an "L"-shaped plate-shaped metal piece, and hinged holes are provided at both ends and inflection points of the "L", and hinged holes are provided on the opposite...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap