Crushing device for natural gas hydrate exploitation

A crushing device and hydrate technology, which is applied to the driving device for drilling in the borehole, production fluid, earthwork drilling and production, etc., can solve the problems of low heat utilization efficiency, slow action of natural gas hydrate layer, and expensive chemical reagents, etc. Achieve high crushing efficiency, improve support reliability and stability, and expand the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

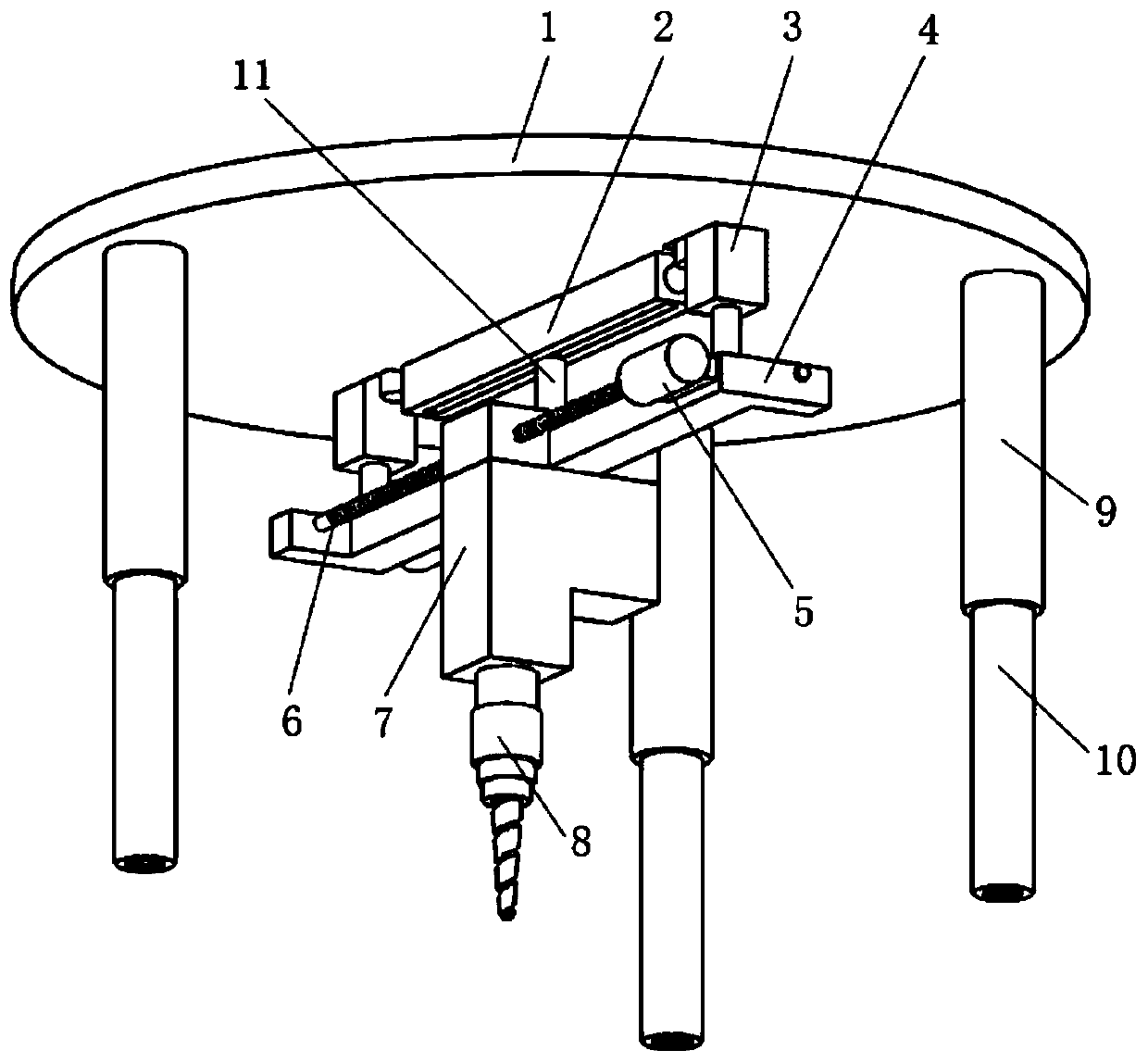

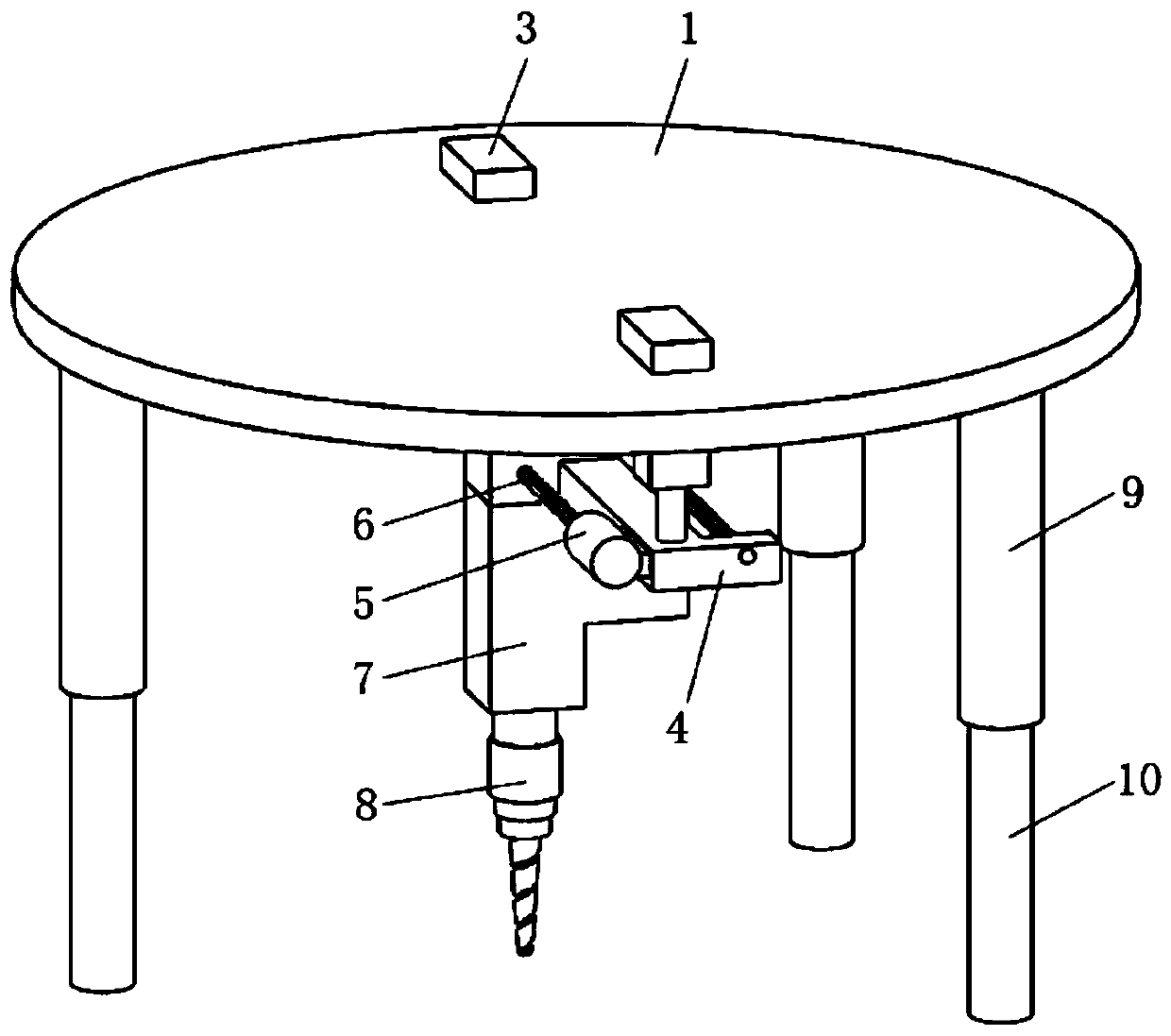

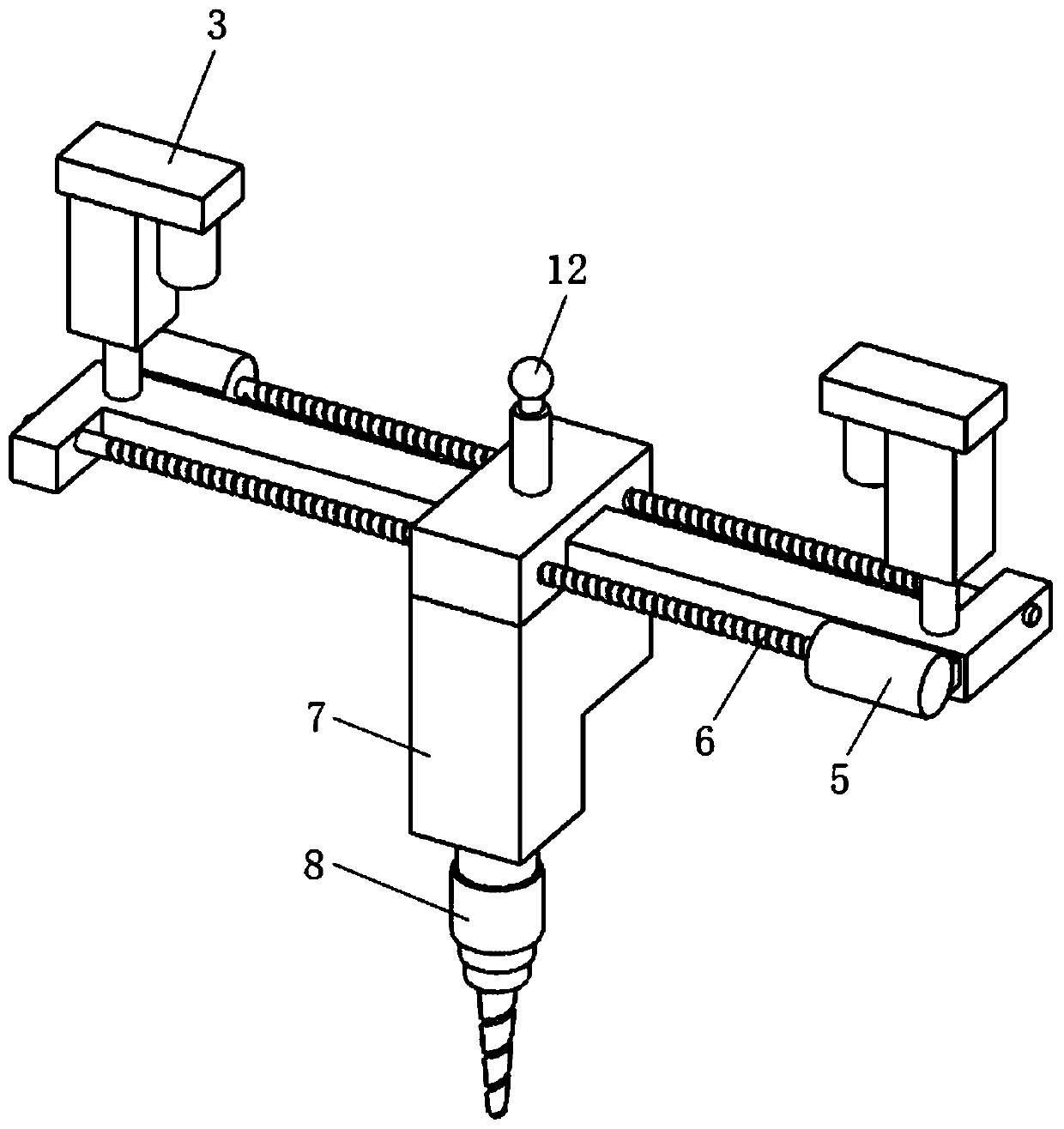

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

[0038] The present invention will be further explained below in conjunction with the drawings and examples:

[0039] In the embodiment of the present invention, a natural gas hydrate opening adopts a crushing device, and an electric push rod pushes the ice nail to rotate in the lower support leg while moving downward to drive the main body of the ice nail to rotate into the natural gas hydrate layer and into the natural gas hydrate layer T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap