Device capable of automatically adjusting balance in operation of asynchronous motor beam pumping unit

A beam pumping unit and asynchronous motor technology are applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc., which can solve the problem that the balance adjustment effect needs to be improved, and achieve the improvement of the balance adjustment effect, reduction of weight, The effect of reducing centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

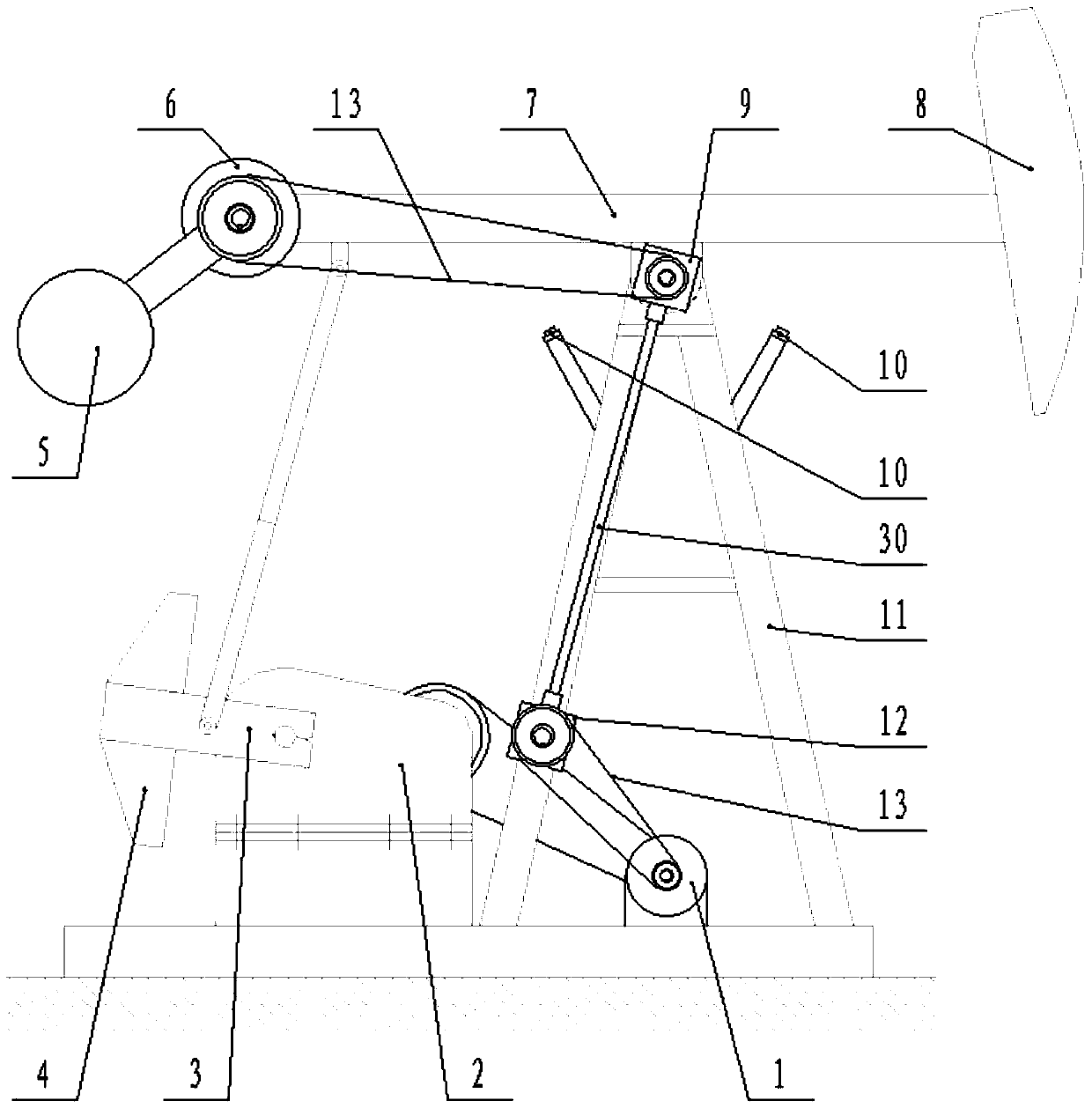

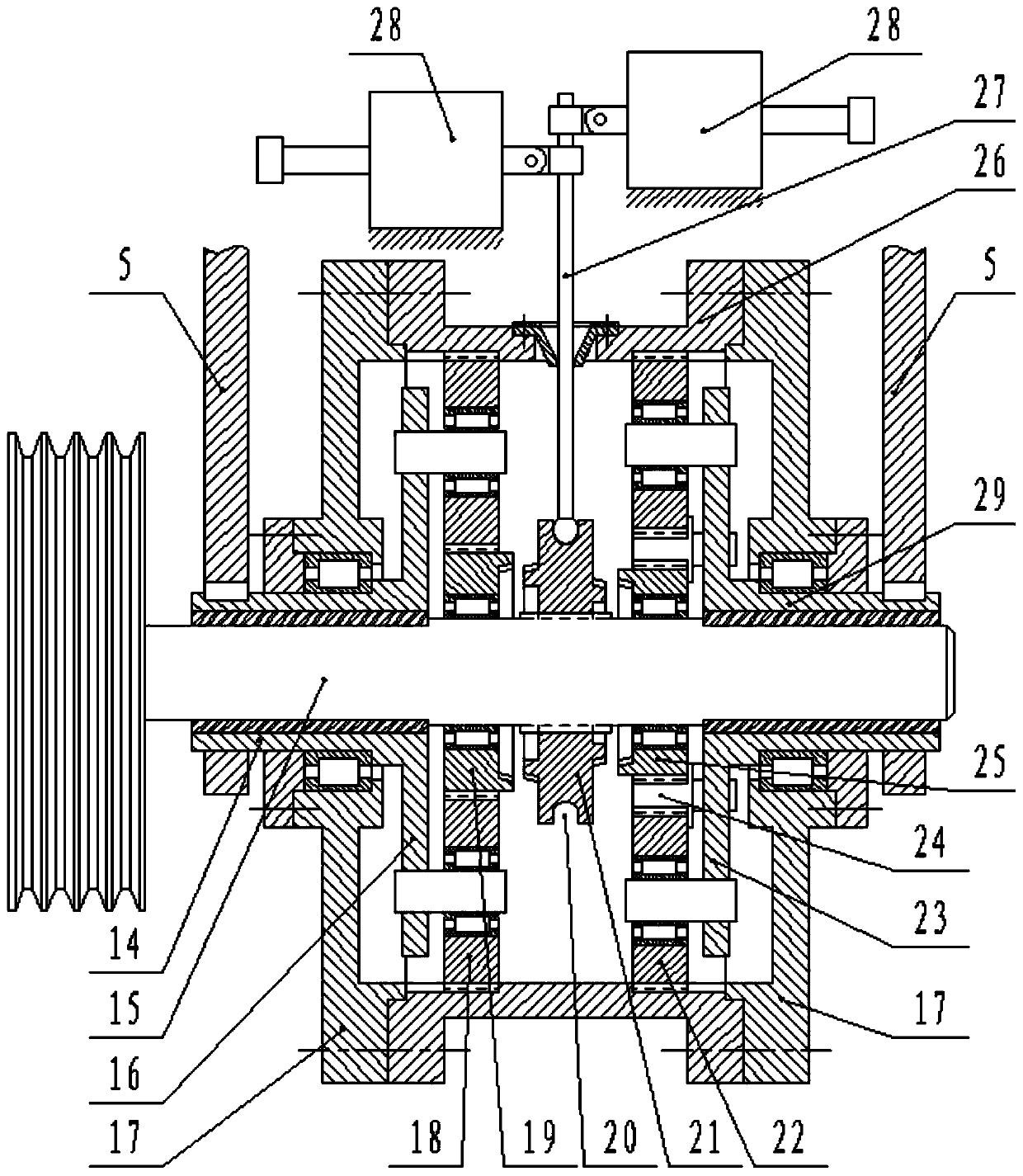

[0024] The present invention comprises a counterweight 5 and a counterweight 4, the counterweight 5 is installed on the tail of the beam 7 of the pumping unit, and the counterweight 4 is installed on the crank 3 of the pumping unit. The above is the basic structure of the existing composite balanced beam pumping unit, and will not be repeated here.

[0025] The innovation of the present invention lies in the installation method of the counterweight 5 on the beam 7 of the pumping unit, specifically:

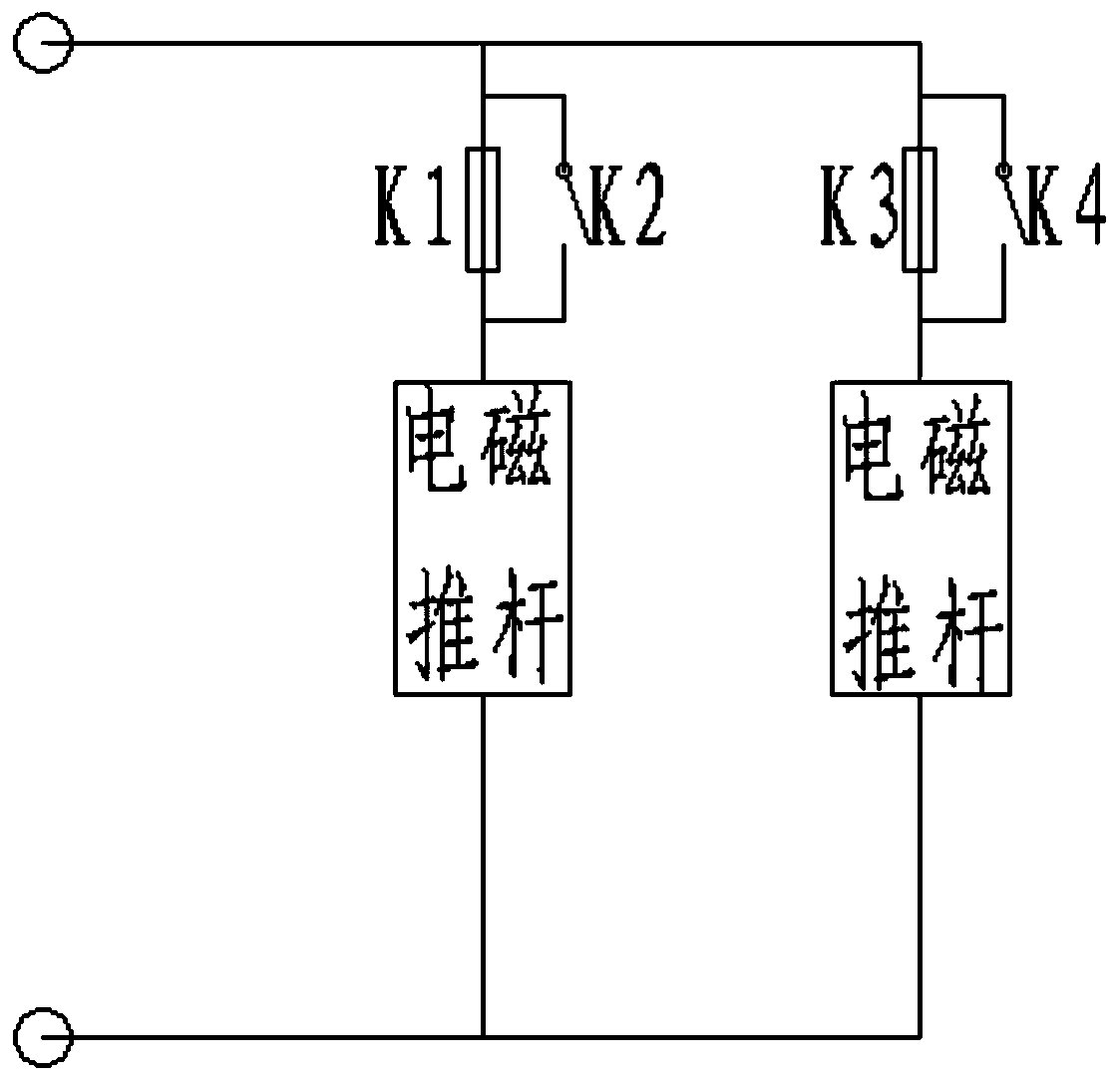

[0026] In the present invention, the tail of the beam 7 of the pumping unit is fixedly provided with a counterweight driver 6, and the counterweight 5 is installed on the output shaft of the counterweight driver 6, and the power of the counterweight driver 6 is provided by the motor 1 of the pumping unit, and the balance The hammer 5 swings back and forth in the vertical plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com