Gas turbine engine

一种气体涡轮、引擎的技术,应用在燃气轮机装置、涡轮/推进装置的进气口、喷气推进装置等方向,能够解决噪音、短舱热损害、增加气体涡轮引擎核心重量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

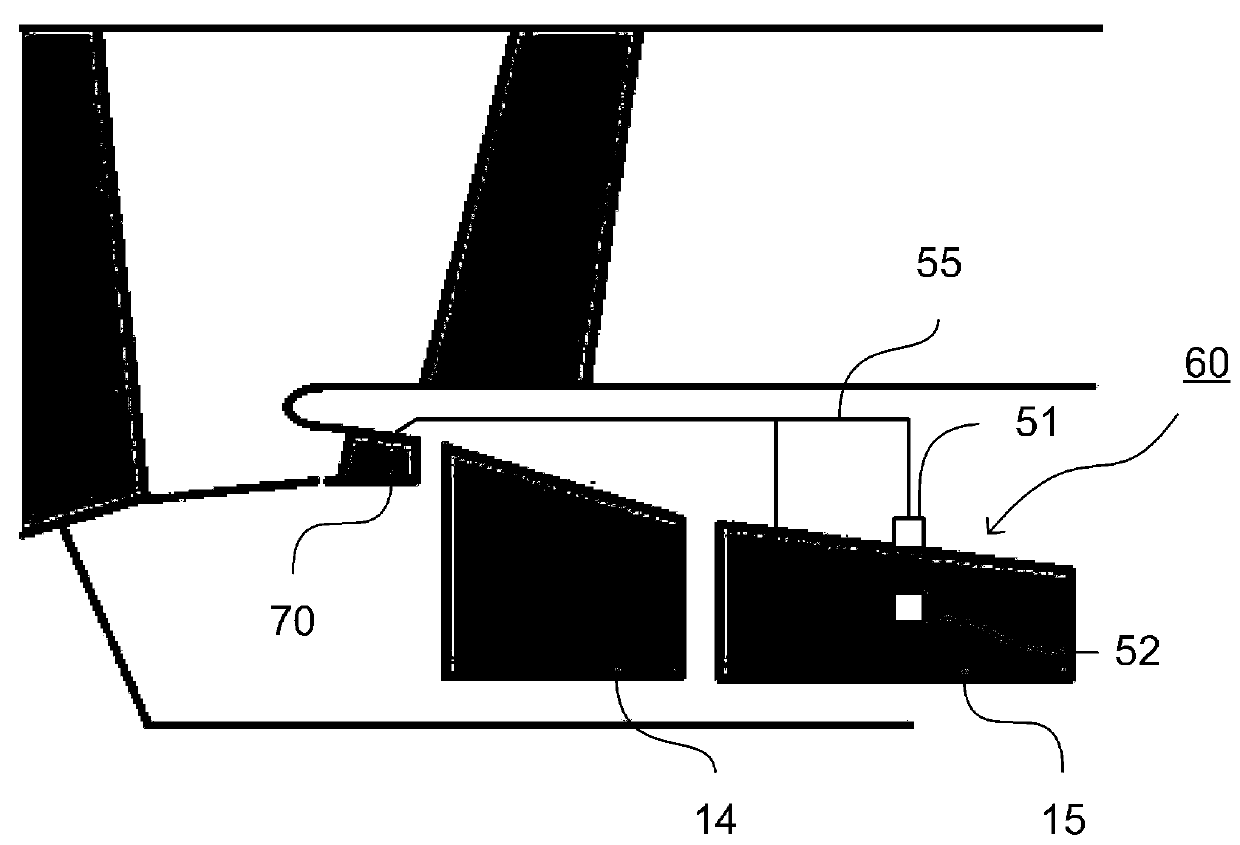

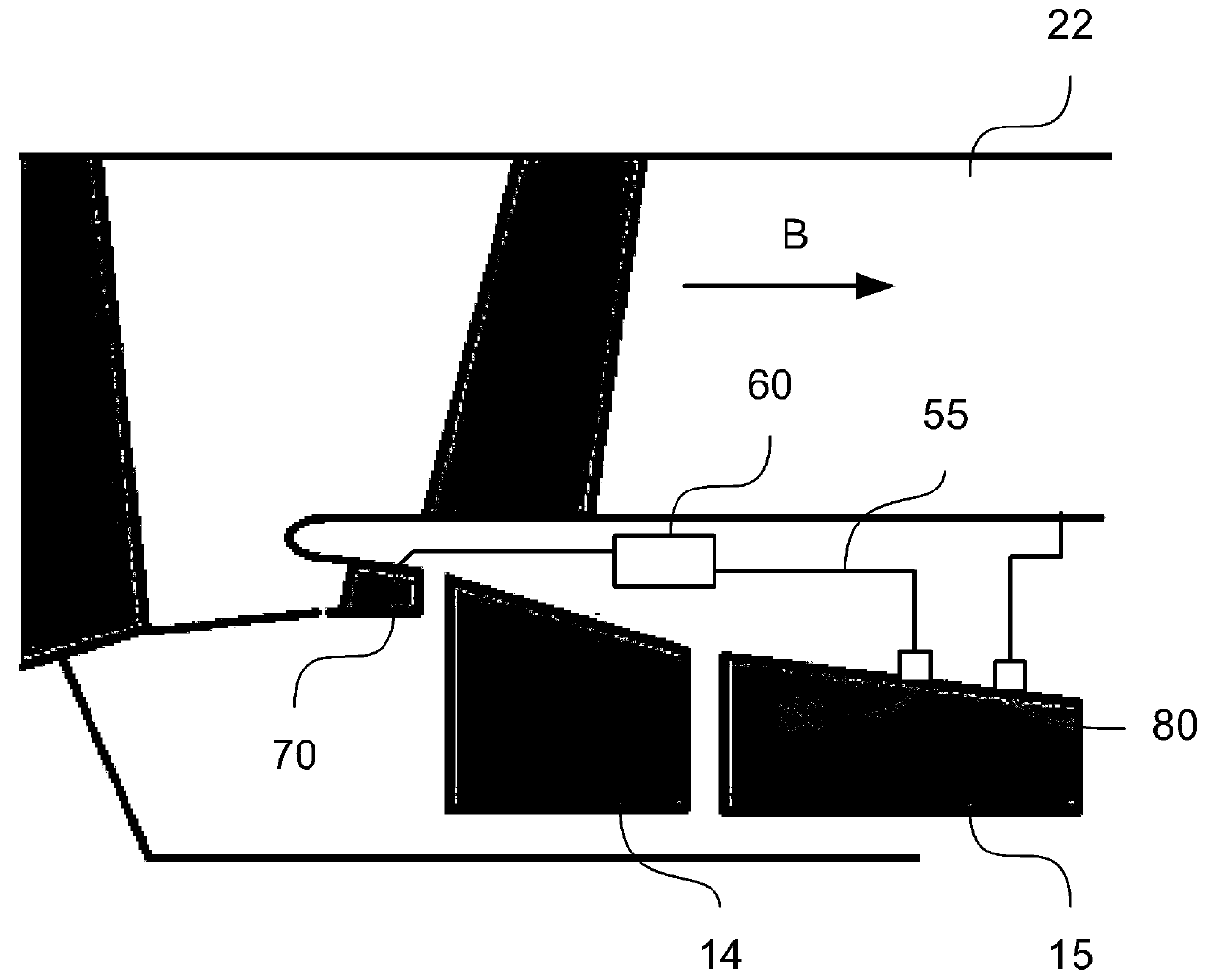

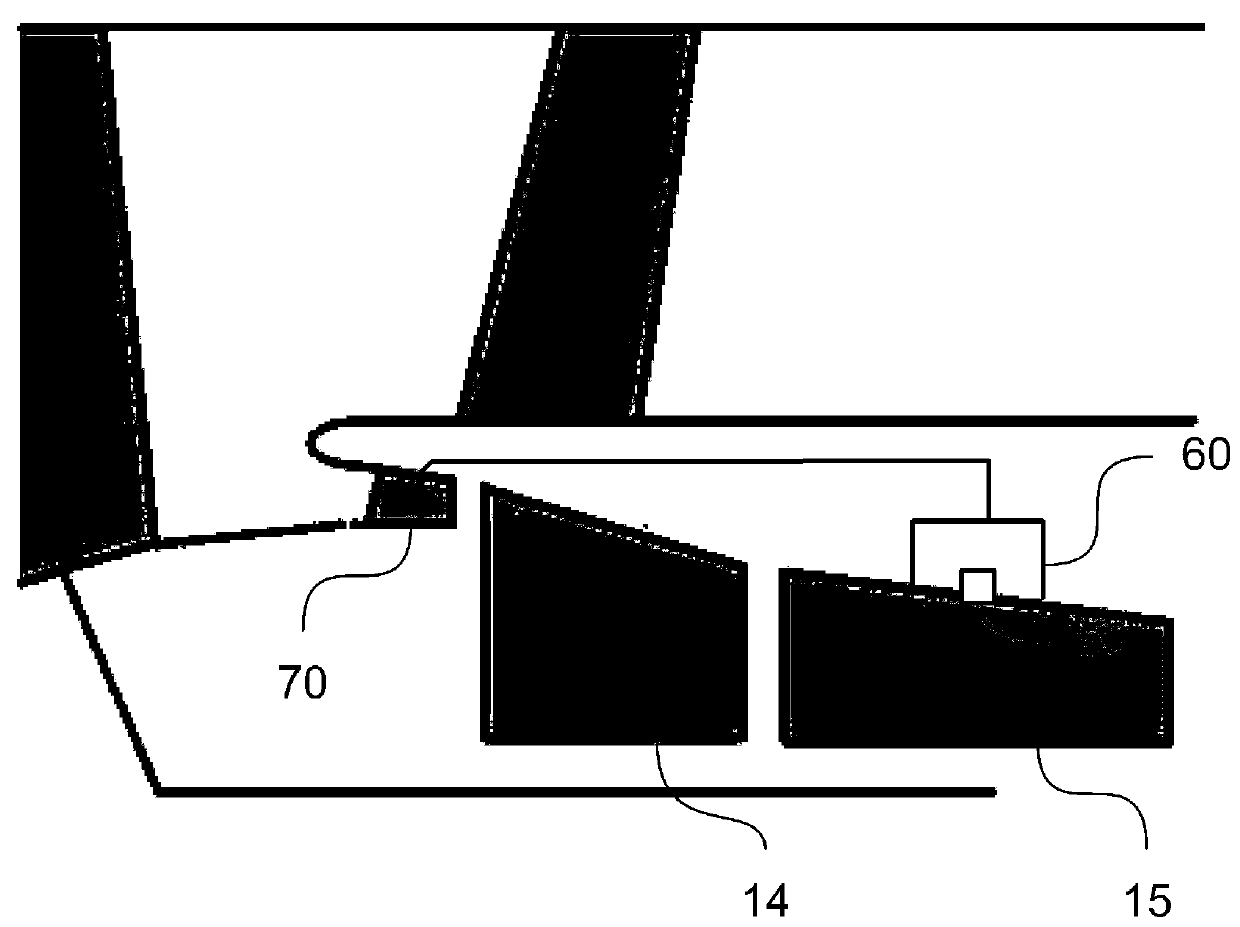

[0040] As noted elsewhere herein, the present disclosure relates to gas turbine engines. Such gas turbine engines may include an engine core including a turbine, a combustor, a compressor, and a mandrel connecting the turbine to the compressor. Such gas turbine engines may include a fan (with fan blades) located upstream of the engine core.

[0041] The arrangement of the present disclosure may be particularly, but not exclusively, beneficial for fans driven via a gearbox. Accordingly, the gas turbine engine may include a gearbox receiving input from the spindle and driving output to the fan to drive the fan at a lower rotational speed than the spindle. The input to the gearbox may come directly from the spindle or indirectly from the spindle, for example via spur shafts and / or gears. The mandrel may rigidly connect the turbine and compressor so that the turbine and compressor rotate at the same speed (where the fan rotates at a slower speed).

[0042] A gas turbine engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com