High-efficiency damping device for mechanical equipment

A technology of mechanical equipment and shock absorbers, which is applied in the direction of mechanical equipment, springs/shock absorbers, supporting machines, etc., and can solve problems that affect the service life of mechanical equipment, the inability to adjust the shock absorption force, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

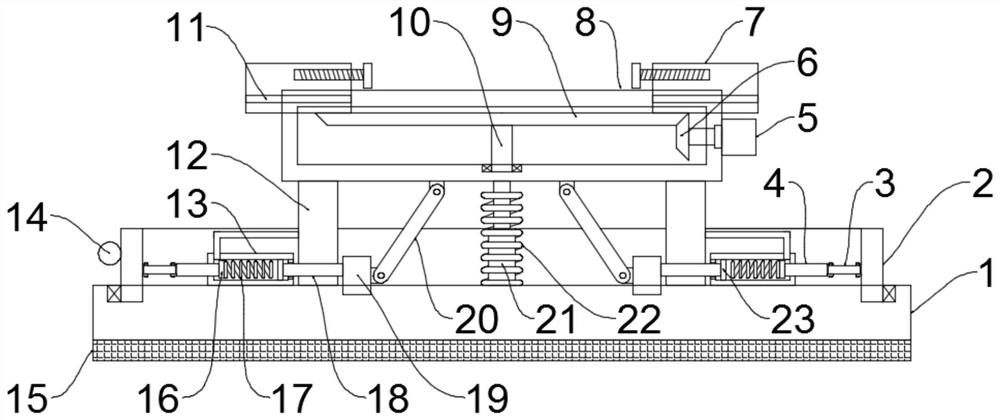

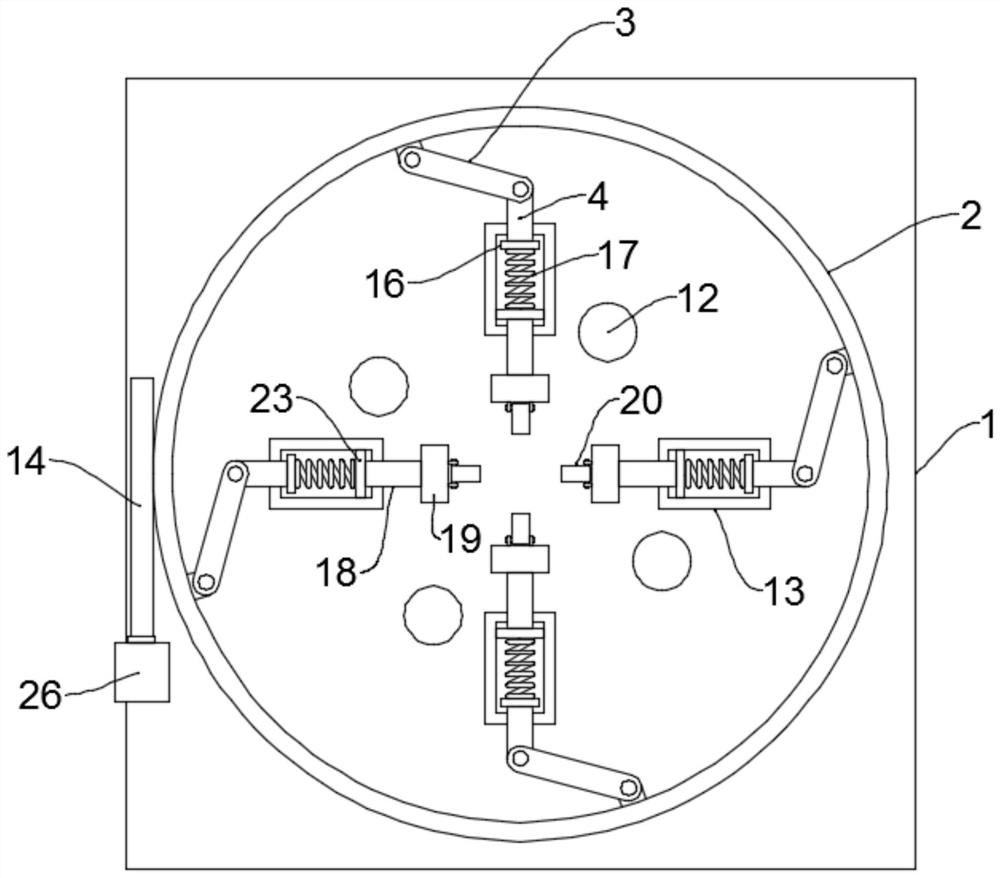

[0023] see Figure 1~3 , in an embodiment of the present invention, a high-efficiency shock absorbing device for mechanical equipment includes a base 1, a mounting seat 8 for installing mechanical equipment, and a shock absorbing mechanism. Mounting seat 8 is arranged on base 1 top, and is connected with shock-absorbing mechanism between mounting seat 8 and base 1, and described shock-absorbing mechanism comprises telescoping rod 21, first spring 22, worm screw 14, worm wheel ring 2, first connecting rod 3 , adjusting rod 4, cylinder block 13, adjusting plate 16, second spring 17, piston 23, piston rod 18, movable block 19 and second connecting rod 20, telescopic rod 21 is installed in the middle of the bottom of the mounting base 8, telescopic rod The bottom end of 21 is fixedly connected with the upper surface of the base 1, the first spring 22 is sheathed on the outside of the telescopic rod 21, and there are multiple second connecting rods 20 hinged at the bottom of the mo...

Embodiment 2

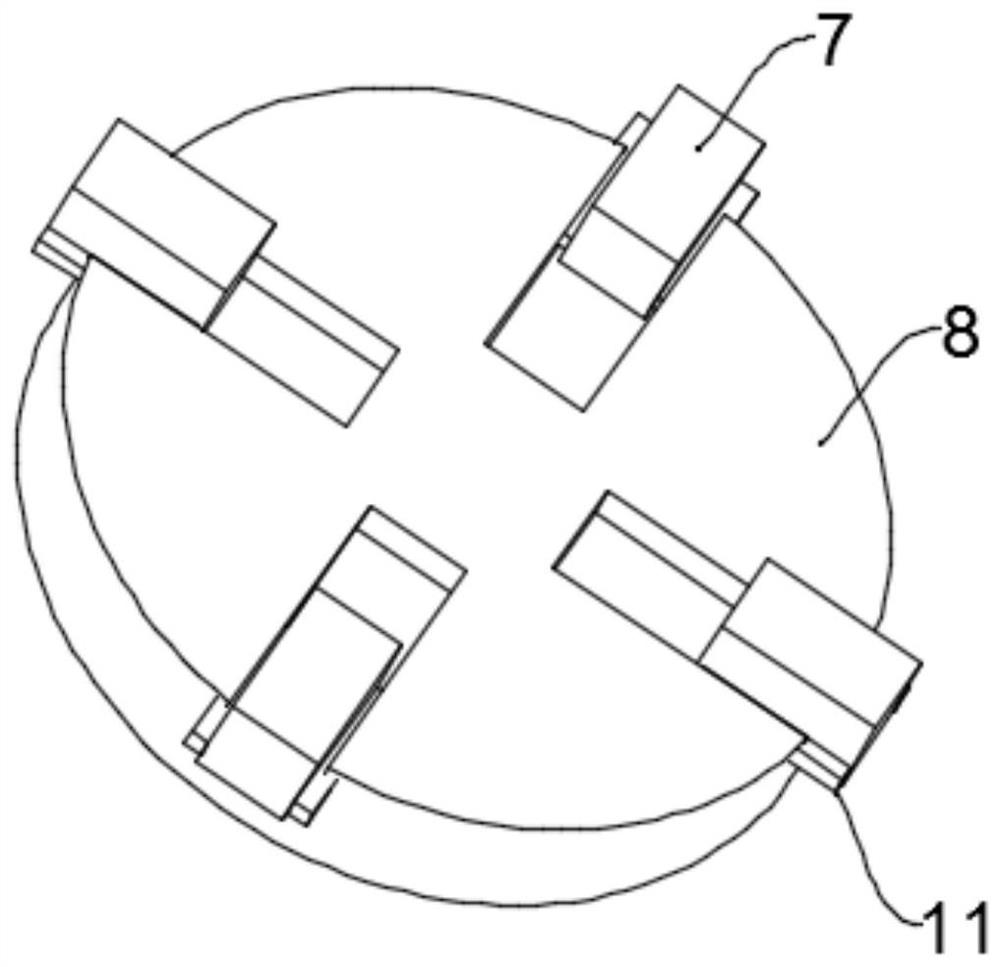

[0027] see Figure 4The difference between this embodiment of the present invention and Embodiment 1 is that further, in order to prevent the rapid rebound of the mounting seat 8 when the equipment is removed, causing accidents or affecting the stability of the device, the lower part of the side wall of the mounting seat 8 A plurality of gears 24 are installed in rotation, and the gears 24 and the clamping positioning block 7 are misplaced. The rack 25 meshing with the gears 24 is fixed on the base 1. Through the meshing of the gears 24 and the rack 25, the gears 24 and the teeth The meshing of the bar 25 plays a certain role of speed limit and prevents the fast rebound of the mounting seat 8 .

[0028] The working principle of the present invention is: when the present invention is in use, put the mechanical equipment on the mounting base 8, then start the first stepping motor 5, and the first stepping motor 5 drives the second bevel gear 9 to rotate through the first bevel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com