L-shaped frame assembling jig

A technology for assembling fixtures and center positioning, which is applied in the field of fixtures, can solve problems such as welding failure, no positioning, motor scrapping, etc., and achieve the effect of good welding, good positioning, and not easy to be relatively dislocated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

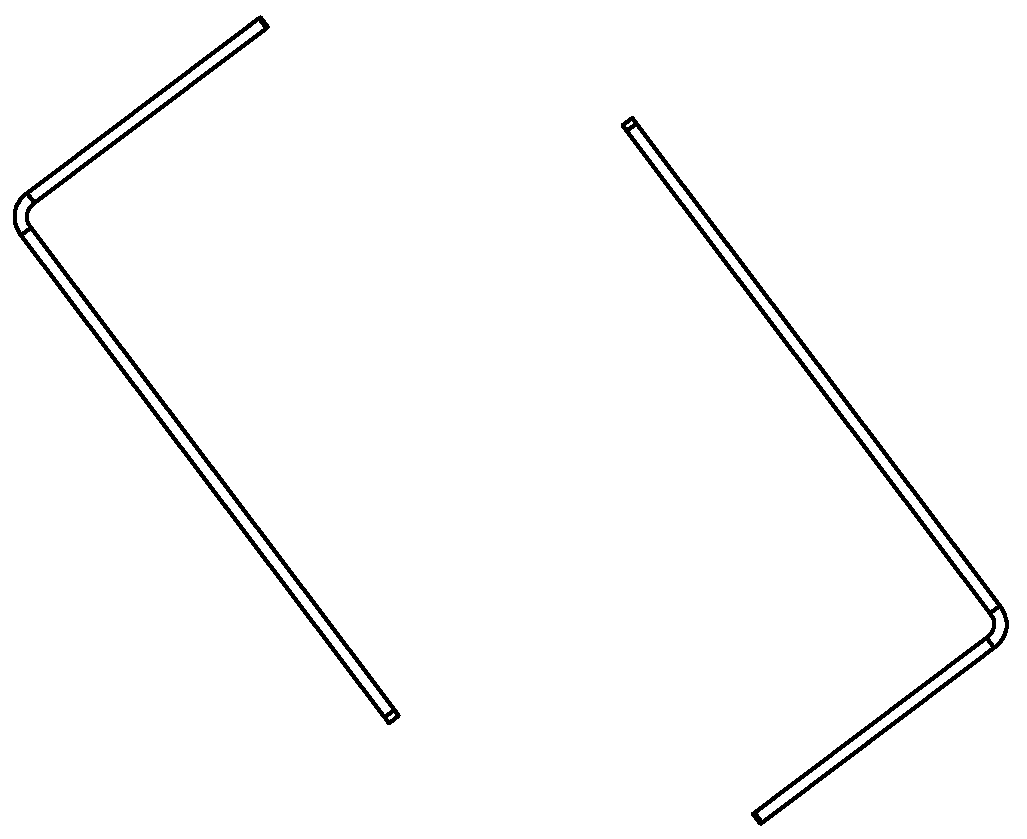

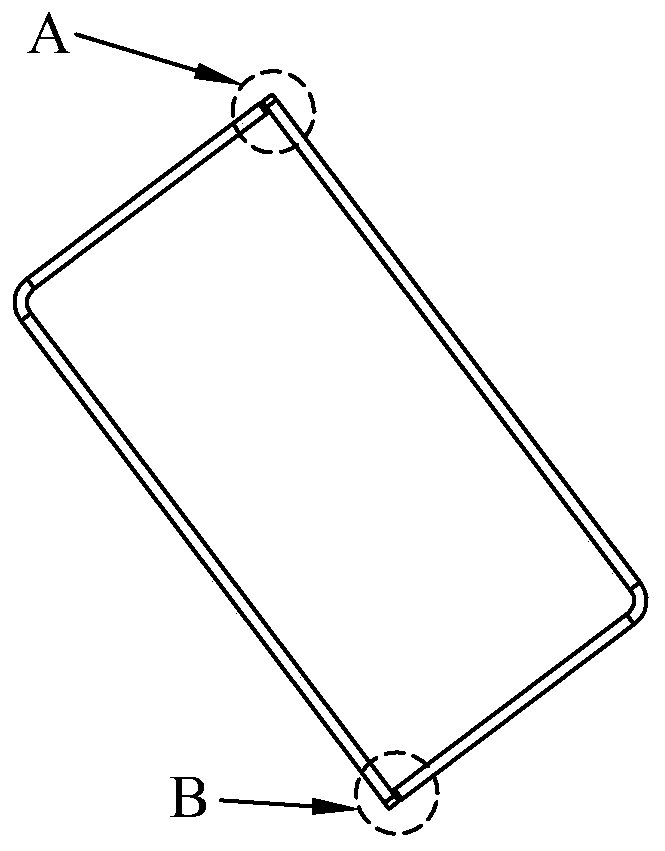

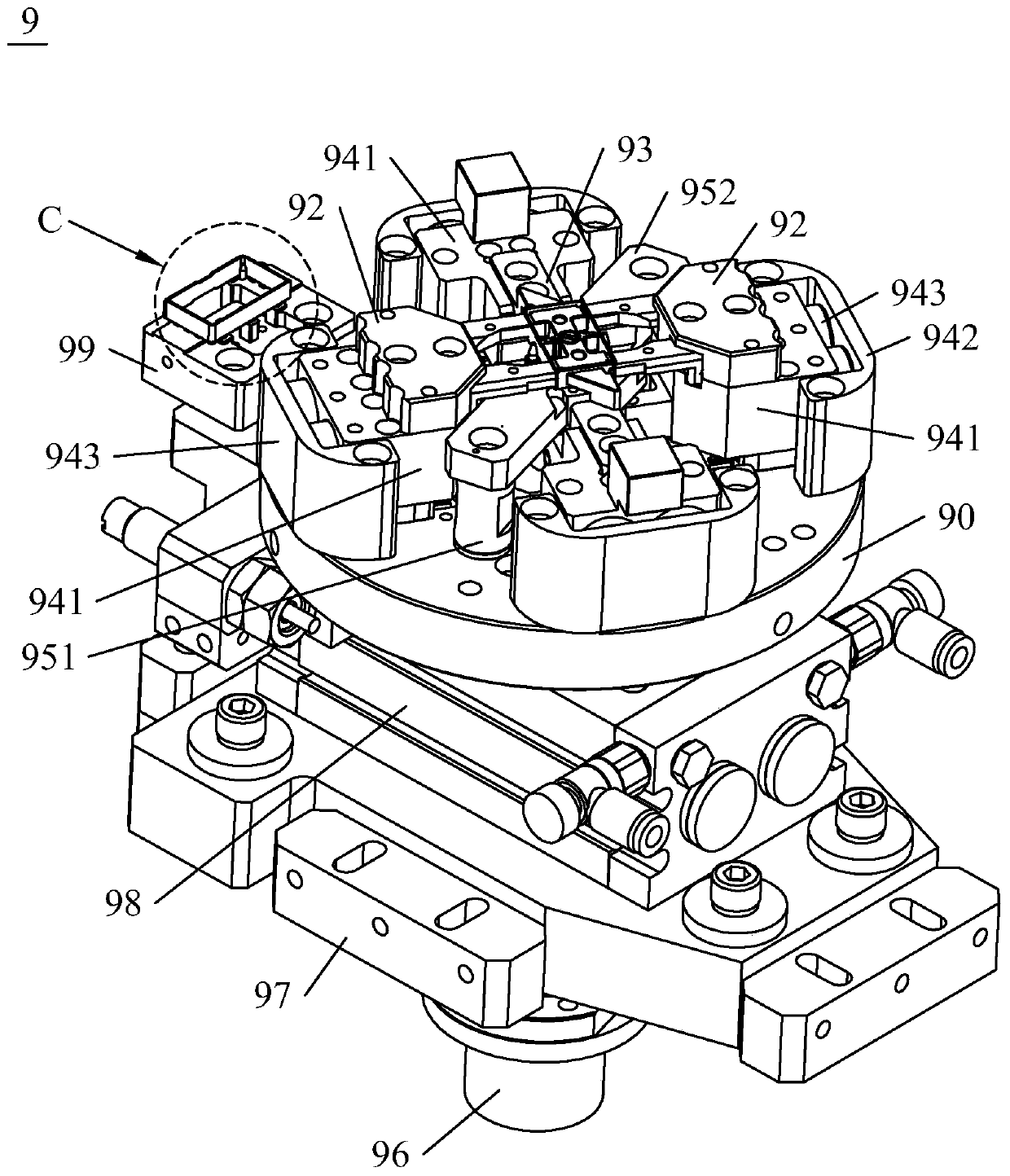

[0026] combine Figure 3 to Figure 5 As shown, the present invention provides a kind of L frame assembly fixture 9, is used for figure 1 The two L boxes shown in the figure 2 The docking status shown in . The L-frame assembly jig 9 includes a bottom plate 90 , a central positioning block 91 and abutting jaws 92 . The center positioning block 91 is fixed in the middle of the base plate 90, and its length and width correspond to the long side and short side size of the L frame respectively, so the two L frames can surround and fit on the outside of the center positioning block 91. Two resisting jaws 92 are slidably arranged on the bottom plate 90 and located on both sides of the central positioning block 91. The resisting jaws 92 can slide close to the central positioning block 91 to press the corresponding L frame against the central positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com