Cutting device for foam sandwich plate

A cutting device and sandwich panel technology, applied in the field of foam plastic production, can solve the problems of small application range, inapplicability of panels, unfavorable promotion and use, etc., and achieve the effect of improving service life and reducing high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

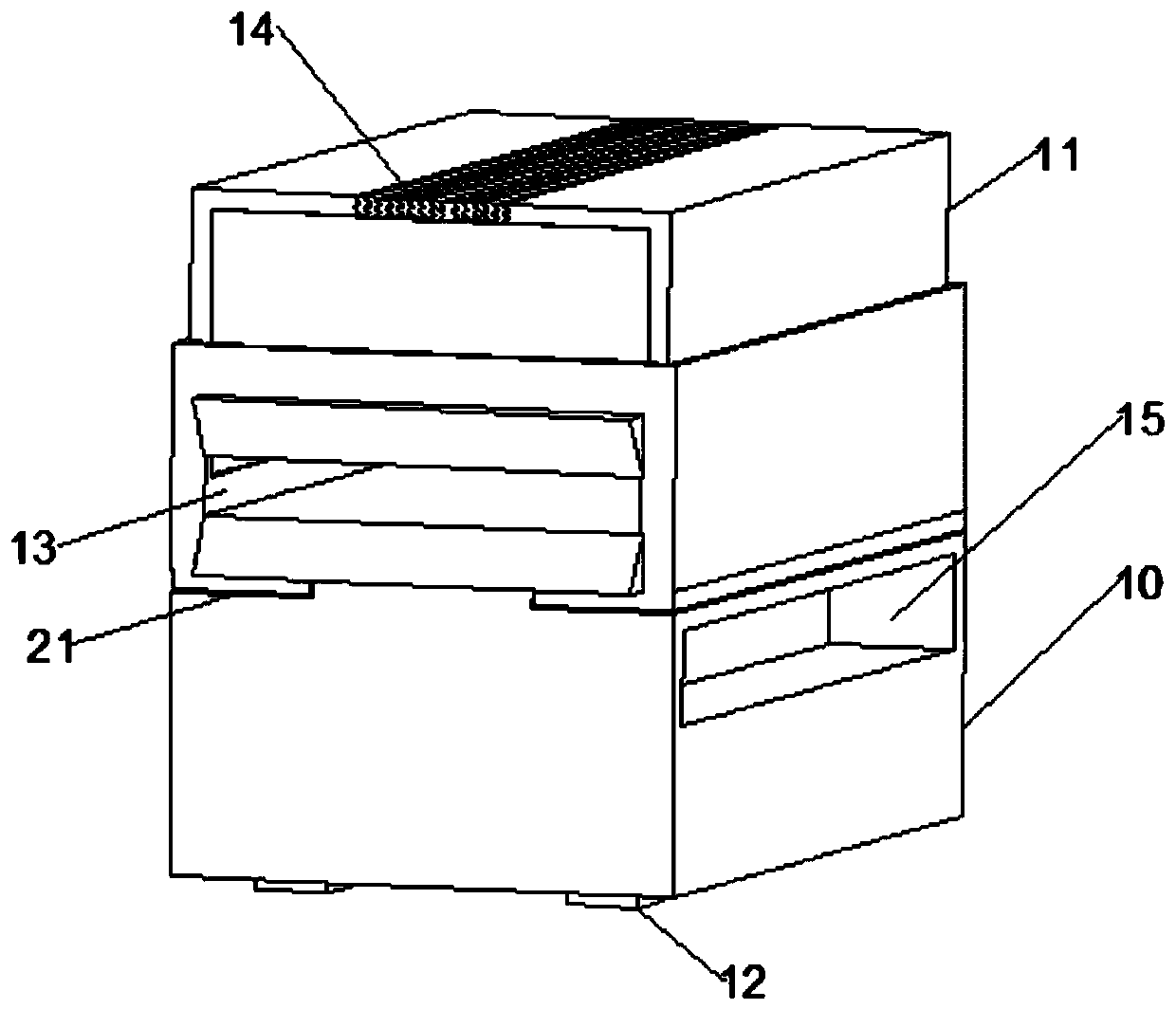

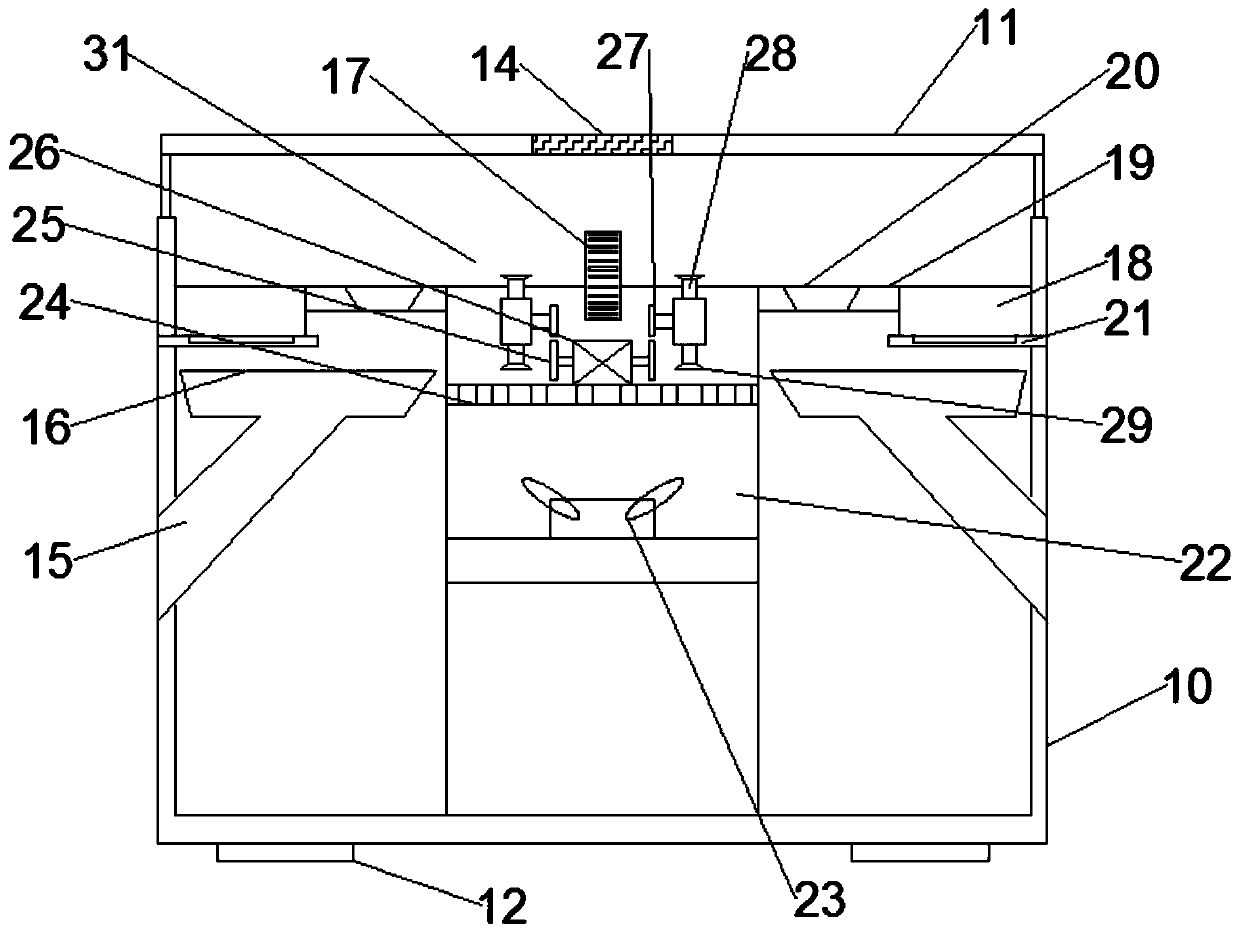

[0020] see Figure 1-2 , a cutting device for a foam sandwich panel, comprising a casing 10, a plate inlet 13, a waste outlet 15 and a cutting knife 17; the four corners of the lower surface of the bottom of the casing 10 are fixedly equipped with anti-slip pads 12, and the anti-slip pads 12 are arranged for improving The stability of the bottom of the casing 10. The front side of the box body 10 is provided with a sheet material inlet 13, and the inside of the sheet material inlet 13 is connected with a cutting channel 31, and the outer end of the sheet material inlet 13 is configured as a trumpet-shaped structure to facilitate the entry of the foam sandwich panel. The box body 10 is arranged as an upper opening shape, and a glass cover 11 is fixedly installed on the top of the box body 10, through which the staff can observe the cutting situation of the foam sandwich panel inside the box body 10. A set of cutting knives 17 is arranged in the middle part of the cutting chann...

Embodiment 2

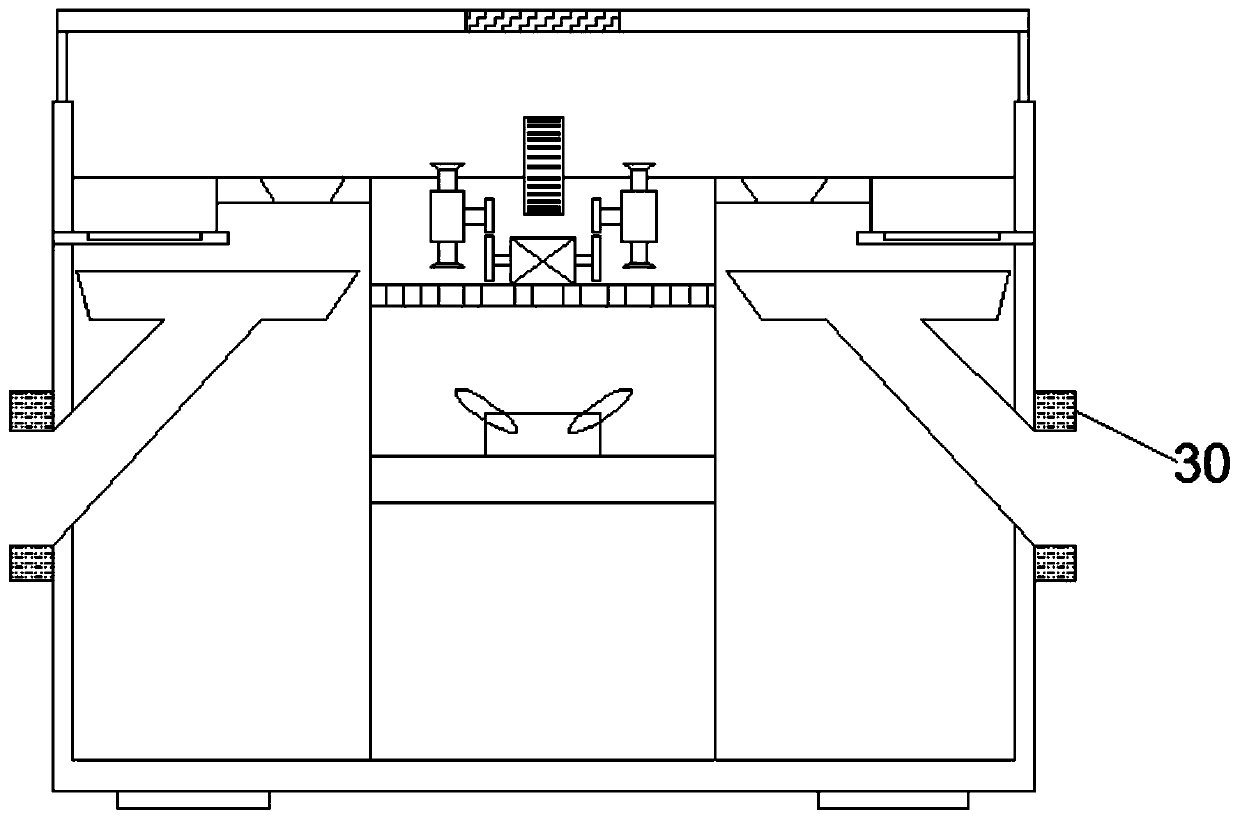

[0024] refer to image 3 , on the basis of Embodiment 1, two sets of exhaust fans 30 are symmetrically installed on the upper and lower sides of the bottom of the waste outlet 15, and by setting the exhaust fans 30 at the bottom of the waste outlet 15, it is convenient to speed up the cutting process of the foam sandwich panel. The output of waste material and dust generated during the process prevents the inside of the waste material outlet 15 from being blocked, which affects the normal use of the cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com