Patents

Literature

44results about How to "Easy to cut and use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

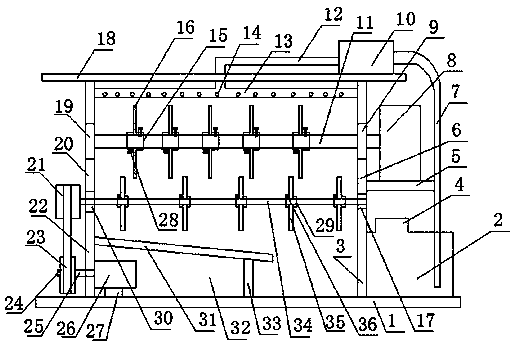

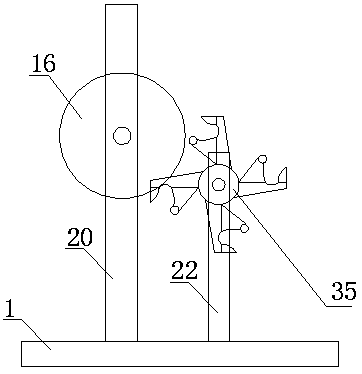

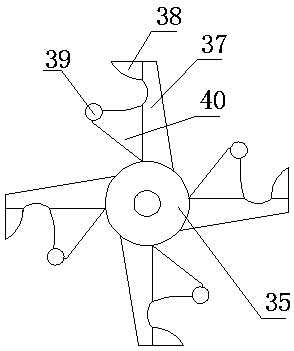

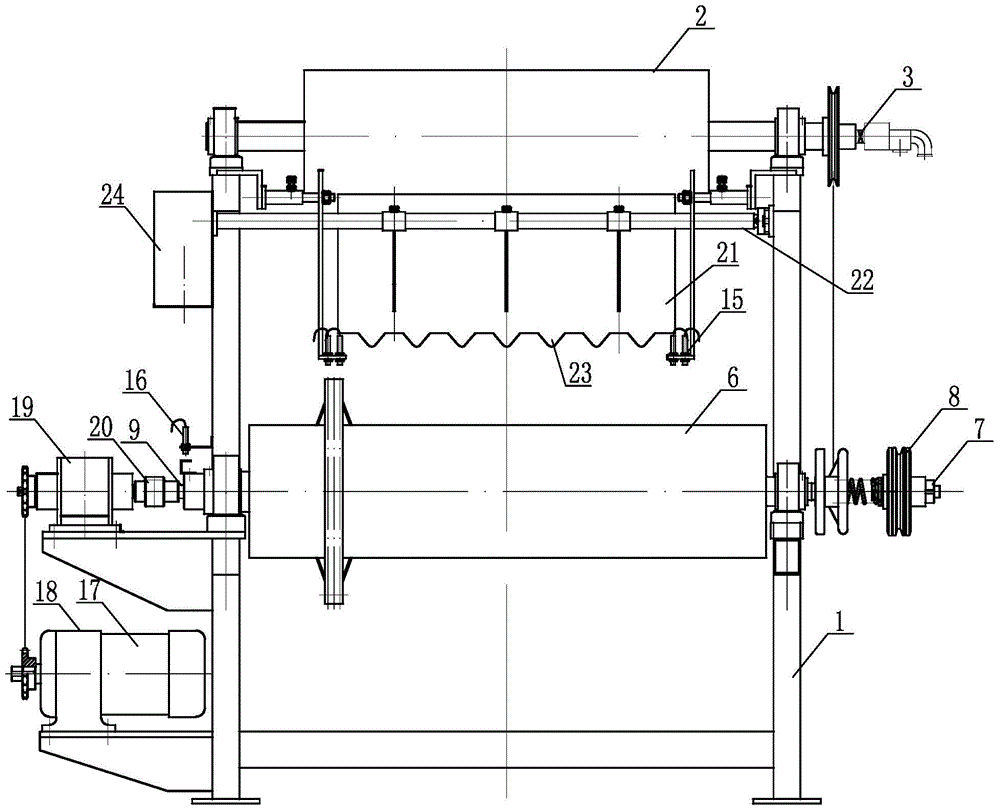

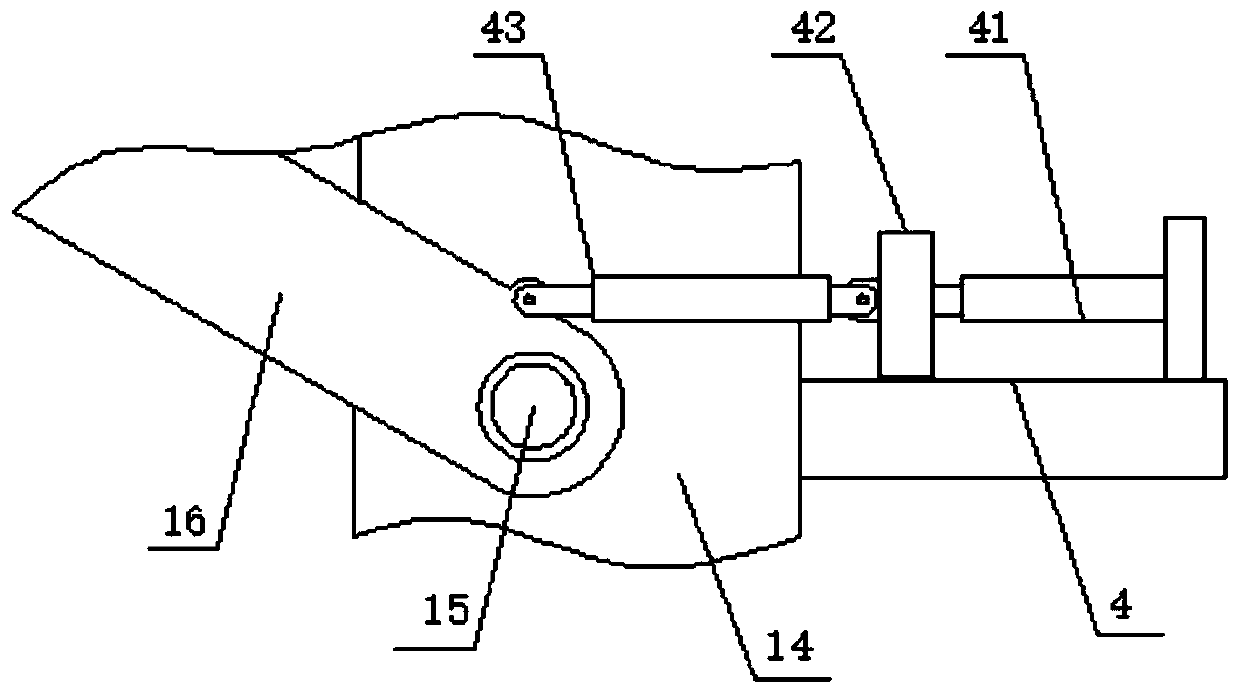

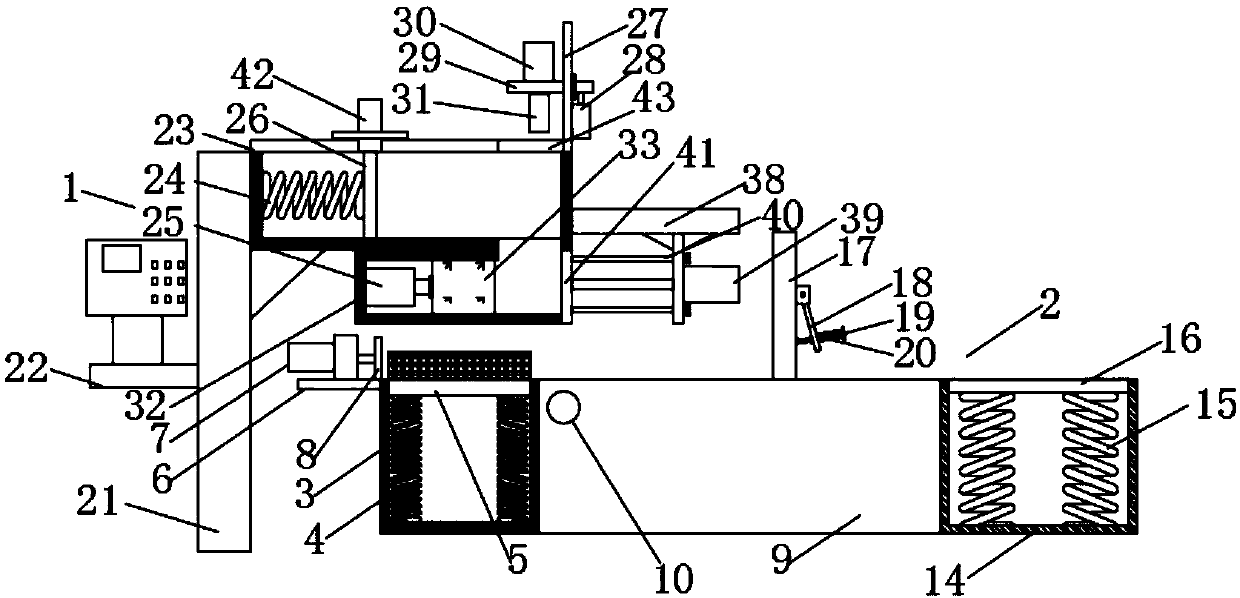

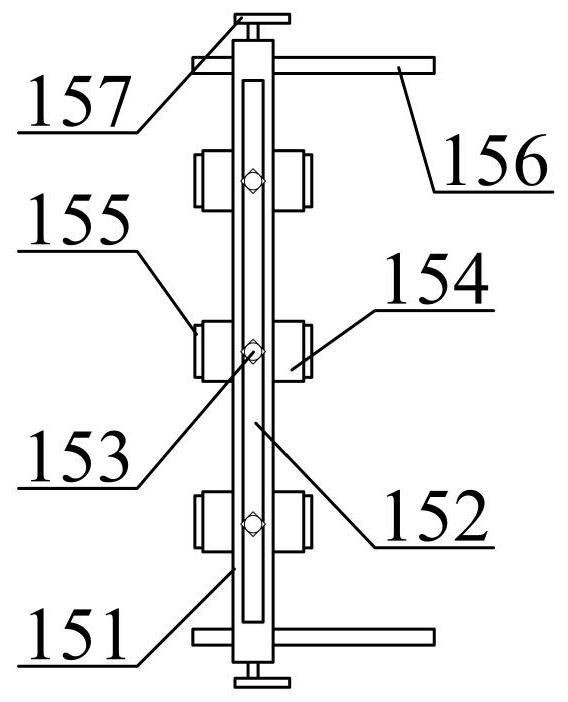

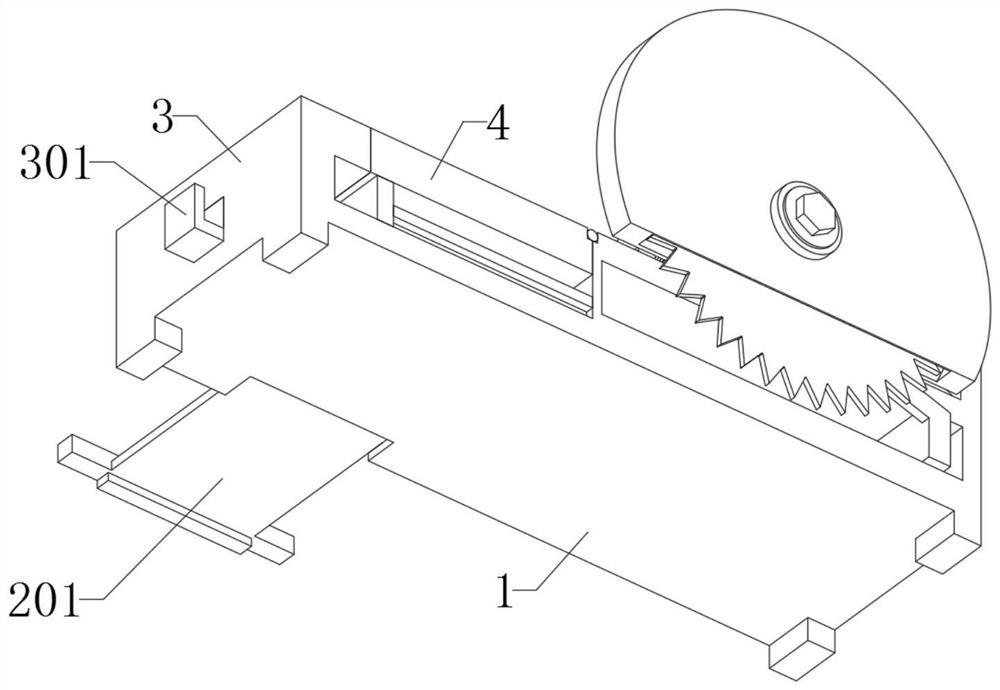

Adjustable-type supporting cutting system and method for furniture producing wood bars

PendingCN108162077AAvoid harmEffective feeding processCircular sawsBark-zones/chip/dust/waste removalBar productEngineering

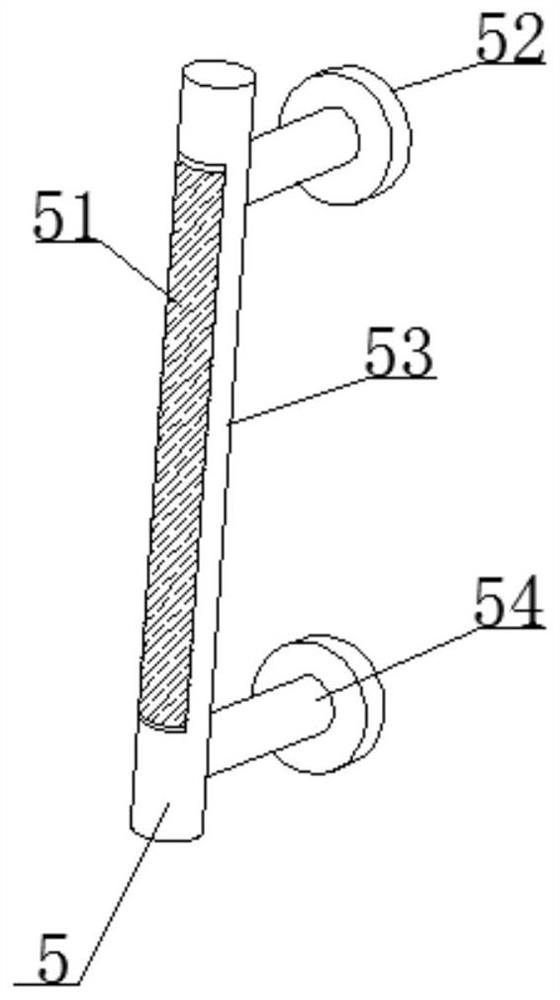

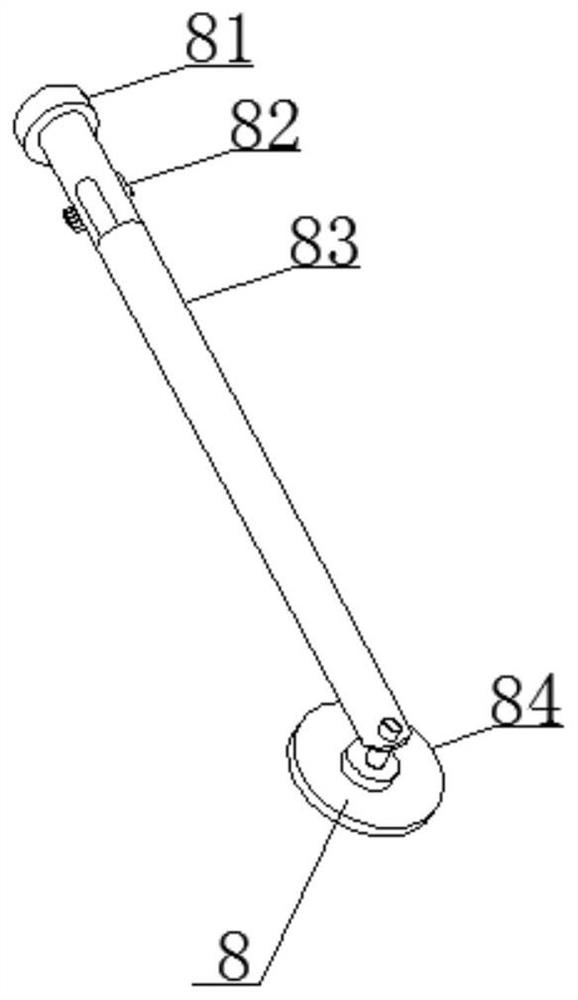

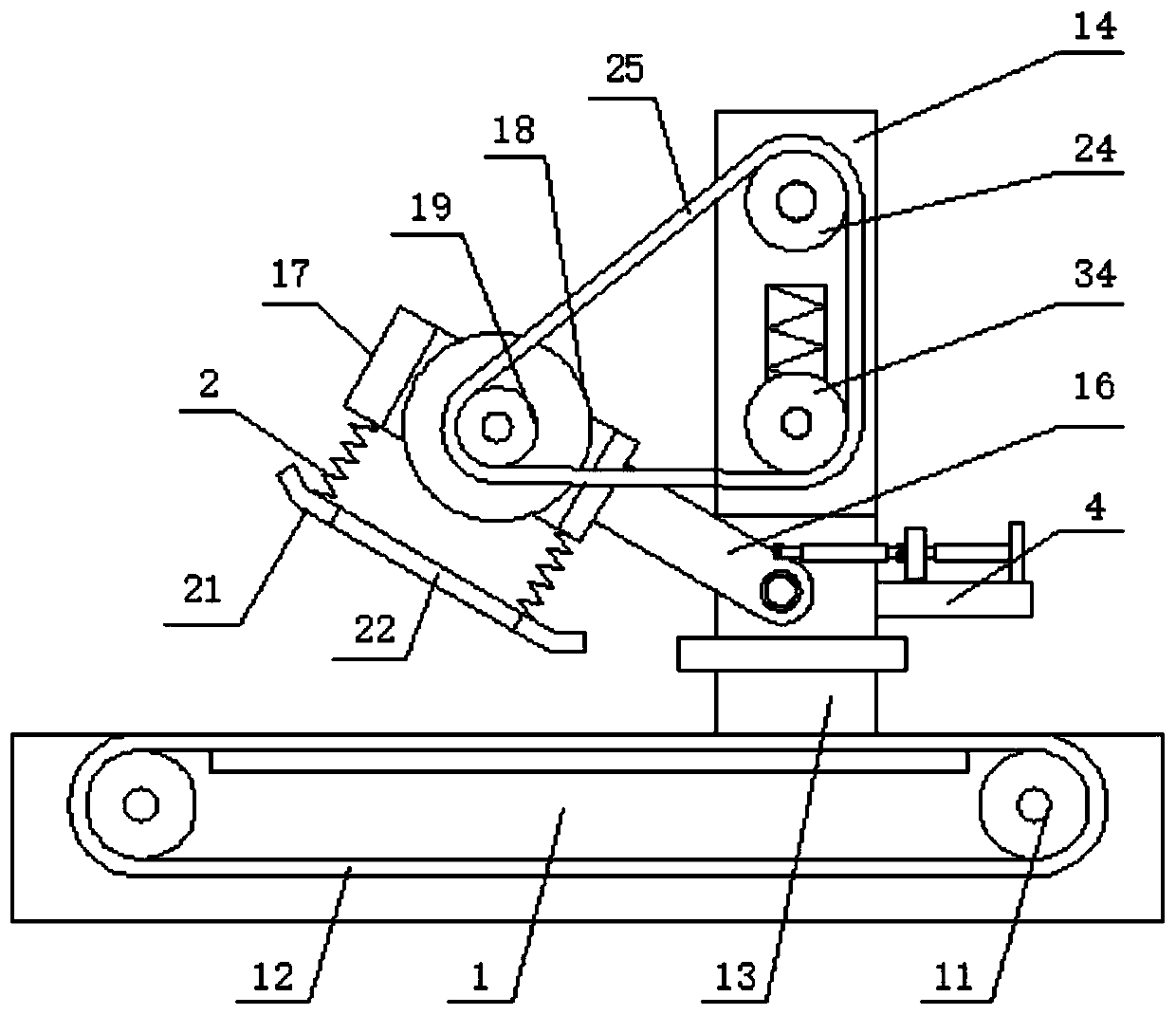

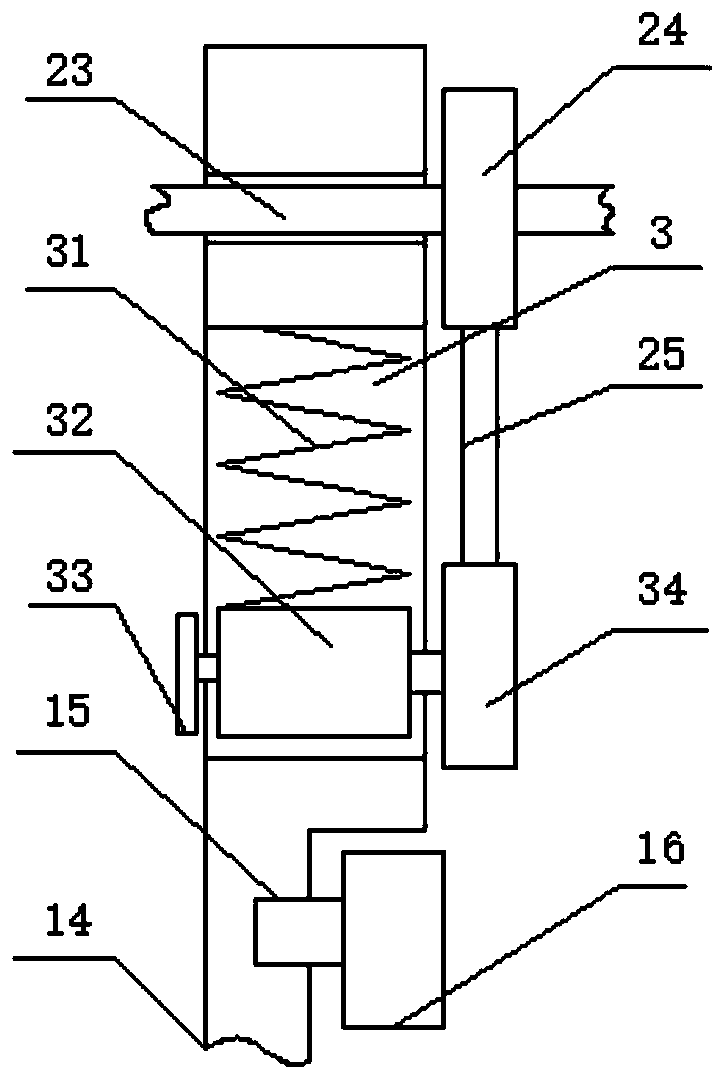

The invention relates to an adjustable-type supporting cutting system for furniture producing wood bars. The adjustable-type supporting cutting system comprises a mounting base. A left feeding supporting column, a left cutting supporting column, a right feeding supporting column and a right cutting supporting column are arranged on the left side face and the right side face of the upper portion ofthe mounting base correspondingly; the left cutting supporting column and the right cutting supporting column are arranged on the rear portions of the left feeding supporting column and the right feeding supporting column correspondingly; a feeding shaft is arranged between the left feeding supporting column and the right feeding supporting column; a plurality of feeding shaft sleeves are arranged in the middle of the feeding shaft, and feeding supporting plates are fixedly connected to the outer circumferences of the feeding shaft sleeves correspondingly; and feeding shaft sleeve fixing studs are arranged on the side faces of the feeding shaft sleeves correspondingly for fixing. The wood bars can be effectively fed and conveniently cut into bar products in different lengths by adjustingthe intervals of cutting sawtooth pieces, and feeding is convenient and safe; and in the cutting treatment process, dust removal is facilitated, the influence of dust is reduced.

Owner:龚完兵

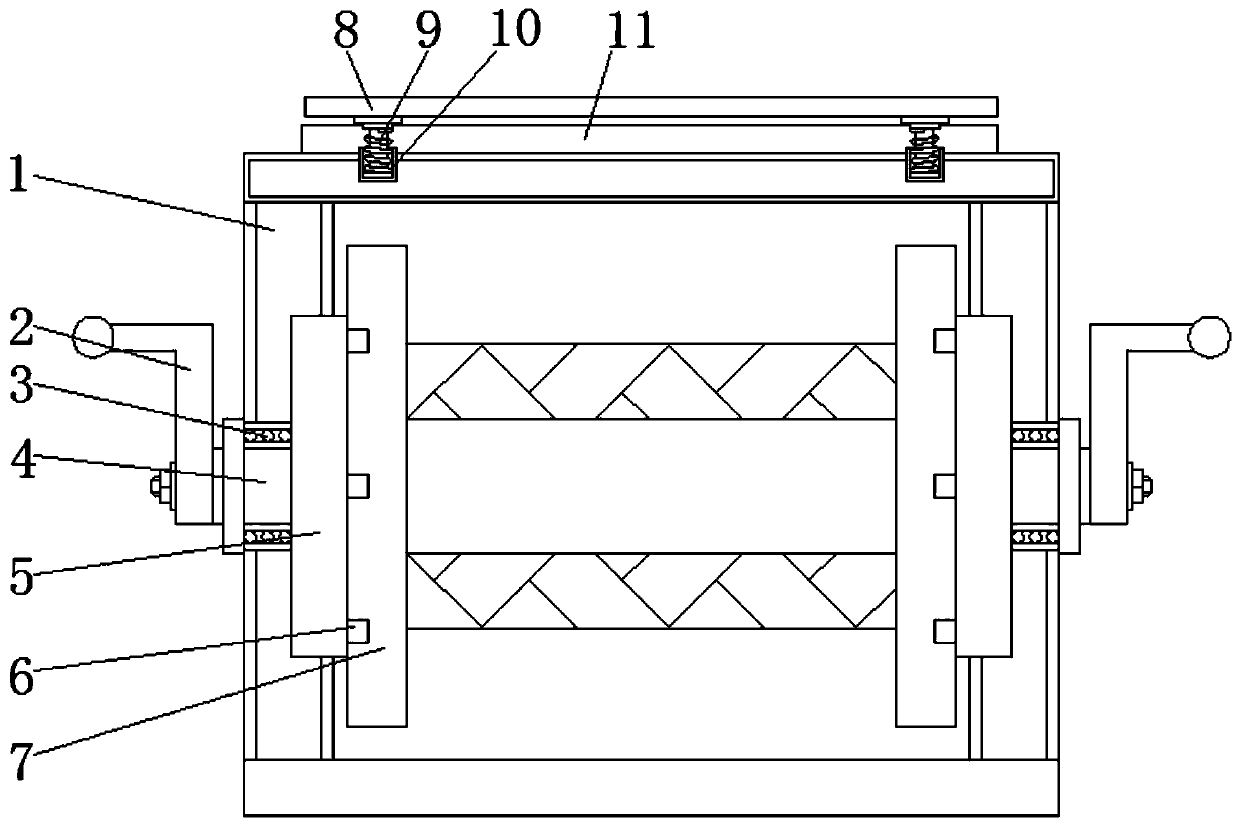

Full-automatic corrugated paper flattening machine

InactiveCN111873553AConducive to auxiliary dischargeEasy to collectMechanical working/deformationMetal working apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of corrugated paper processing, and discloses a full-automatic corrugated paper flattening machine. The machine comprises a rail, multiple supporting legsare fixedly connected to the lower end of the rail, a first conveying belt is arranged on one side in the rail, a second conveying belt is arranged on the other side in the rail, a discharging grooveis fixedly formed in one end of the rail, a protective shell is fixedly connected to the outer side of the upper end of the rail, a feeding port is formed in the end, away from the discharging groove,of the protective shell, a supporting base is arranged on one side of the upper end of the protective shell, two hydraulic rods are fixedly connected to the inner top end of the supporting base, anda fixing base is fixedly connected to the lower ends of the hydraulic rods. According to the full-automatic corrugated paper flattening machine, during use, corrugated paper is put into the flatteningmachine through the feeding port, the first conveying belt drives the corrugated paper to move inwards, the hydraulic rods are started, the two hydraulic rods push the fixing base to descend, the fixing base drives a pressing roller to descend, the pressing roller conducts driving to flatten the corrugated paper on the first conveying belt, and the flattening use of the corrugated paper is facilitated.

Owner:马鞍山威莎自动化设备科技有限公司

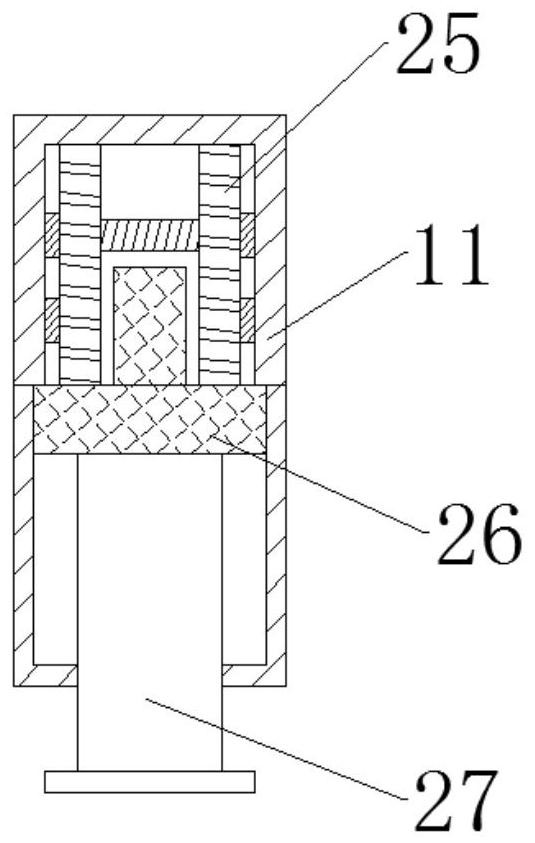

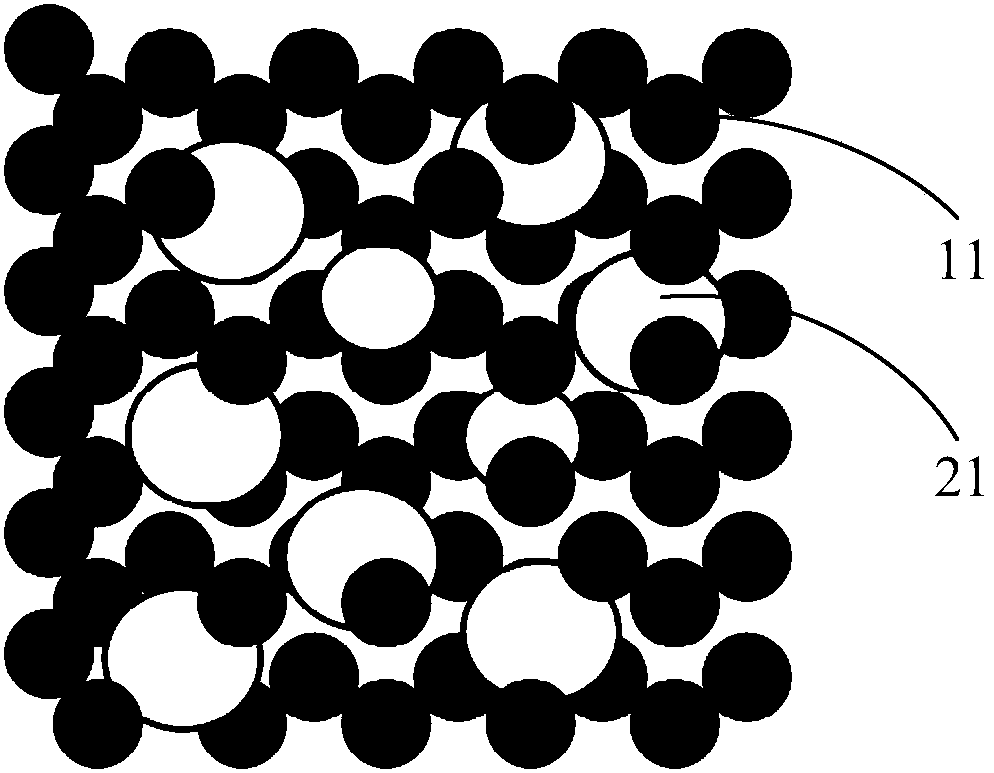

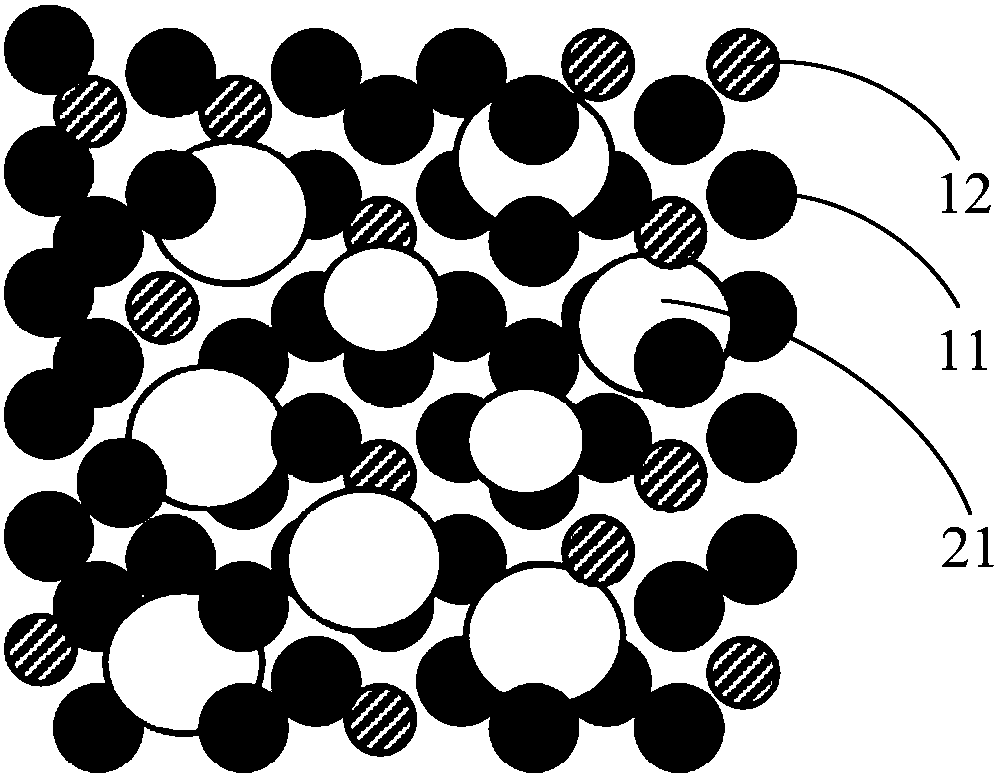

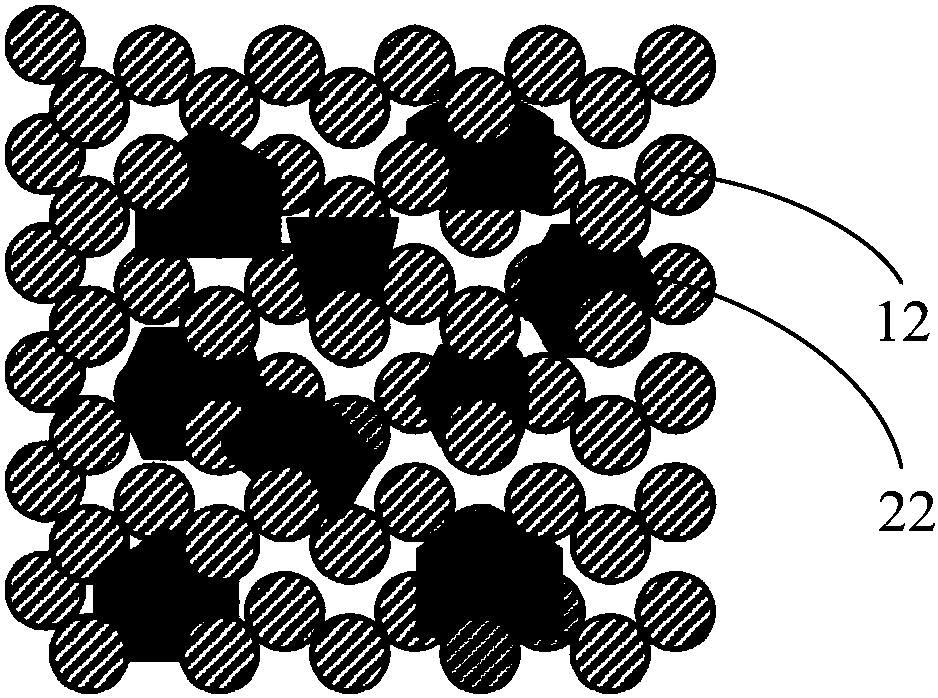

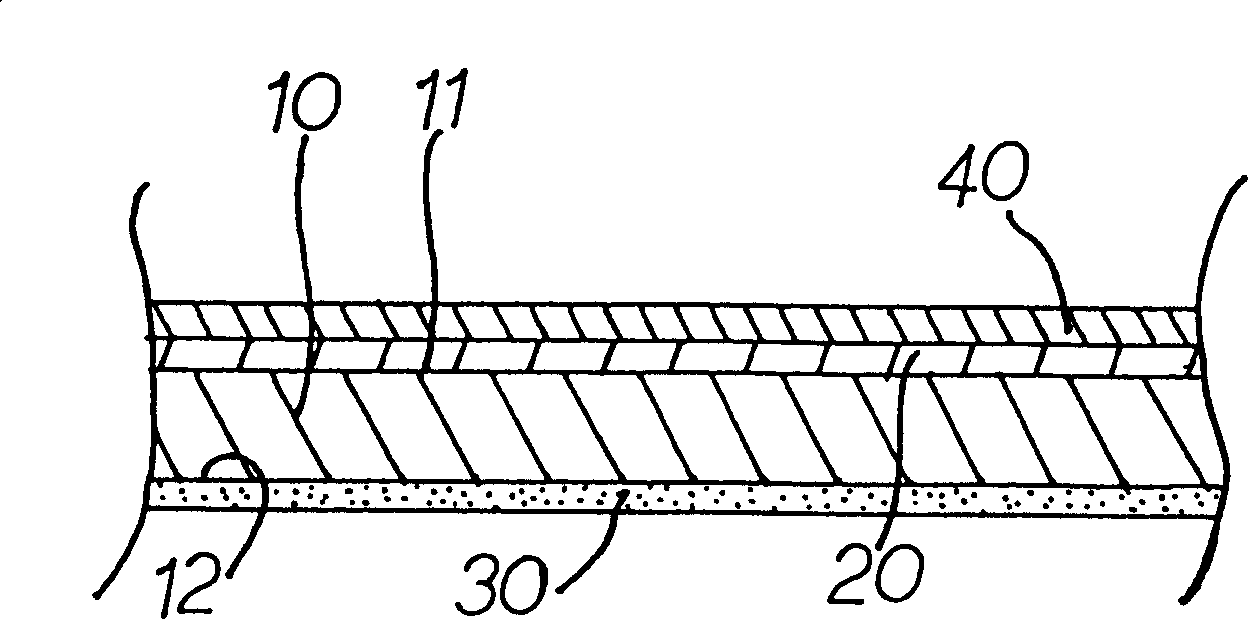

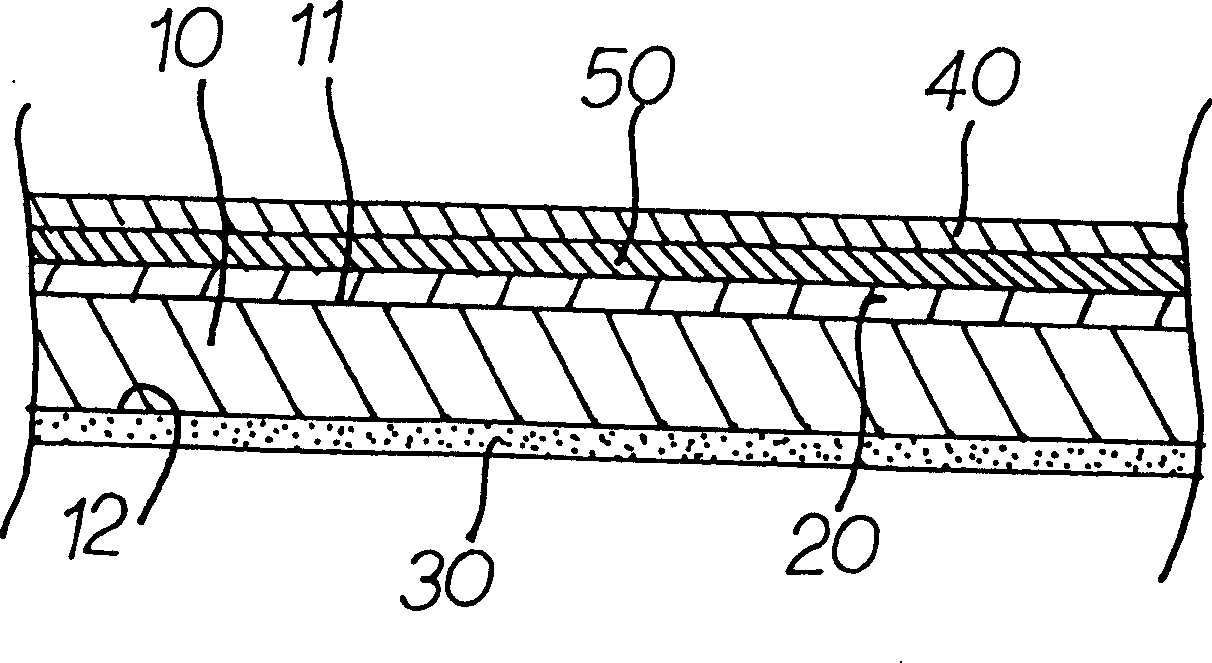

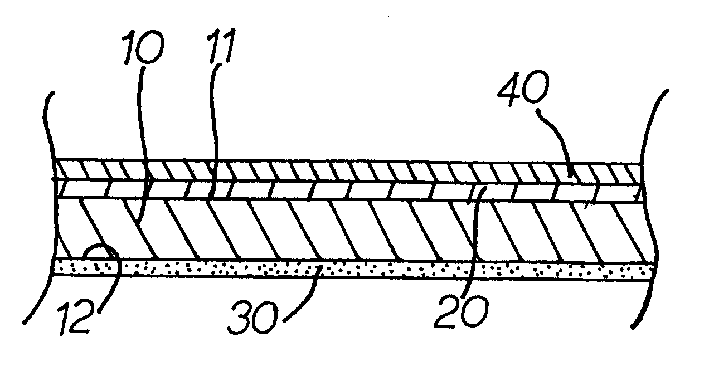

Composite material capable of adsorbing nucleic acid and preparation method thereof, and device capable of adsorbing nucleic acid

ActiveCN108031457AHigh extraction rateLarge apertureAdditive manufacturing apparatusOther chemical processesGlass fiberPorosity

The invention discloses a composite material capable of adsorbing nucleic acid and a preparation method thereof, and a device capable of adsorbing the nucleic acid. The composite material capable of adsorbing the nucleic acid comprises thermoplastic polymer resin, and specific particles or a fibrous material capable of adsorbing the nucleic acid, wherein the specific particles or the fibrous material capable of adsorbing the nucleic acid is glass powder, and / or glass fiber, and / or quartz powder, and / or silica gel powder. With a technical scheme of the invention, the composite material capableof adsorbing the nucleic acid has good flexibility, facilitates cutting and application, can realize bonding with the inner wall of a pipe, and prevents the leakage of a liquid; meanwhile, the porosity is improved; the compatibility of a sample is enhanced; and the variety and complexity of an applicable sample are increased.

Owner:SHENZHEN BIOCOMMA TECH

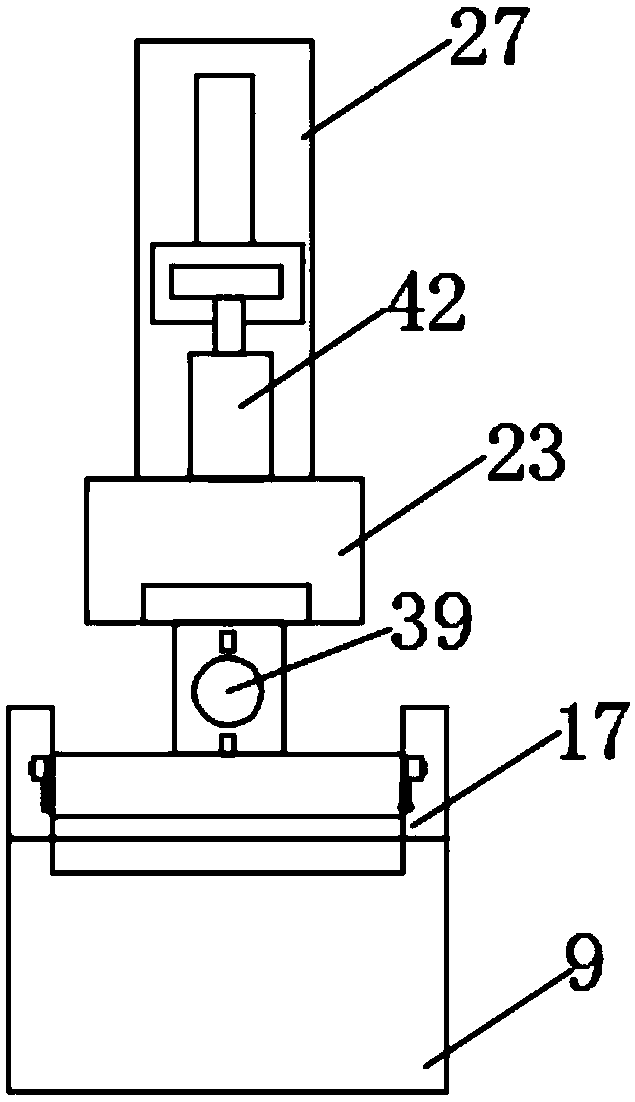

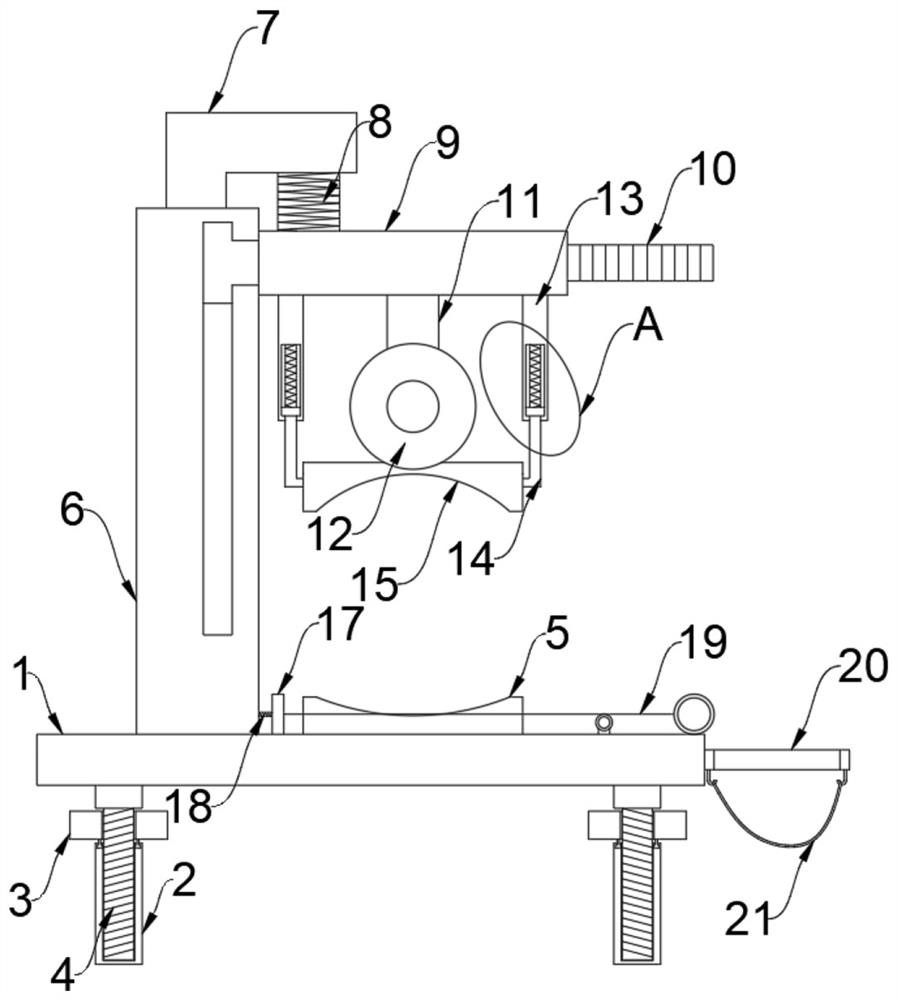

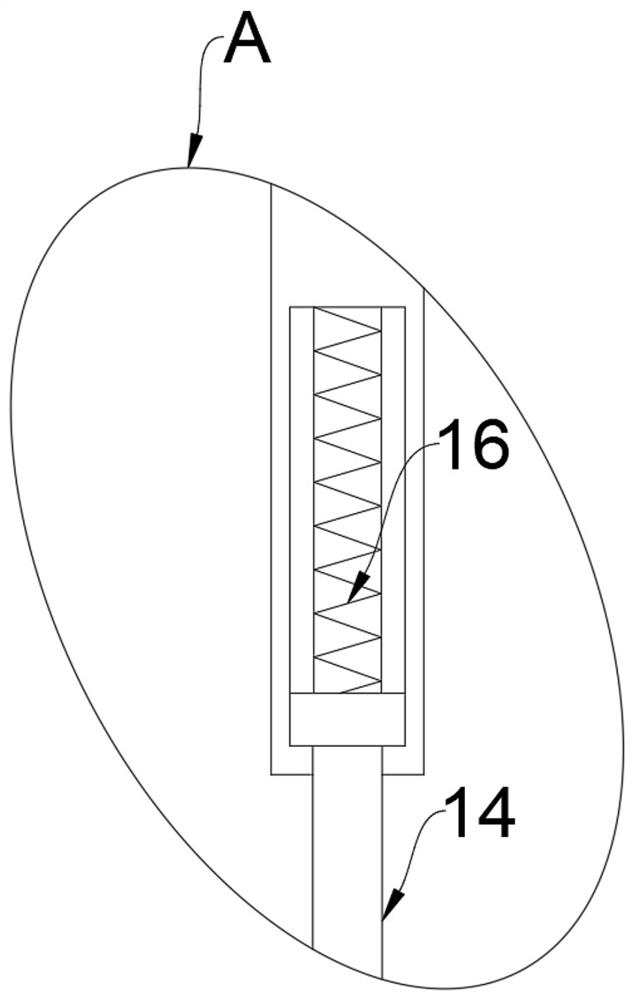

Ceramic tile processing and cutting device with shaping transmission structure

InactiveCN111941667AImprove positioning and clamping efficiencyEasy to useWorking accessoriesStone-like material working toolsBall bearingElectric machine

The invention relates to the technical field of ceramic tile processing, and discloses a ceramic tile processing and cutting device with a shaping transmission structure. The device comprises a workbench, a rotating shaft is rotatably connected to the center of the upper end of the workbench through a ball bearing, a hollow fixed seat is fixedly connected to the upper end of the rotating shaft, and a rotating motor is fixedly connected to the lower end of the workbench. An output shaft at the upper end of the rotating motor is fixedly connected with the lower end of the rotating shaft, the inner walls of the left and right opposite sides of the hollow fixed seat are rotationally connected with two two-way screws through ball bearings in a front-back symmetrical mode, one ends of the two-way screws penetrate through and extend out of the hollow fixed seat and are fixedly connected with driven bevel gears, and the outer wall of the hollow fixed seat is fixedly connected with a first double-shaft motor. The ceramic tile processing and cutting device with the shaping transmission structure has the advantages that the relative position of a cutting knife can be rapidly changed, and adjustment is convenient for cutting use.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

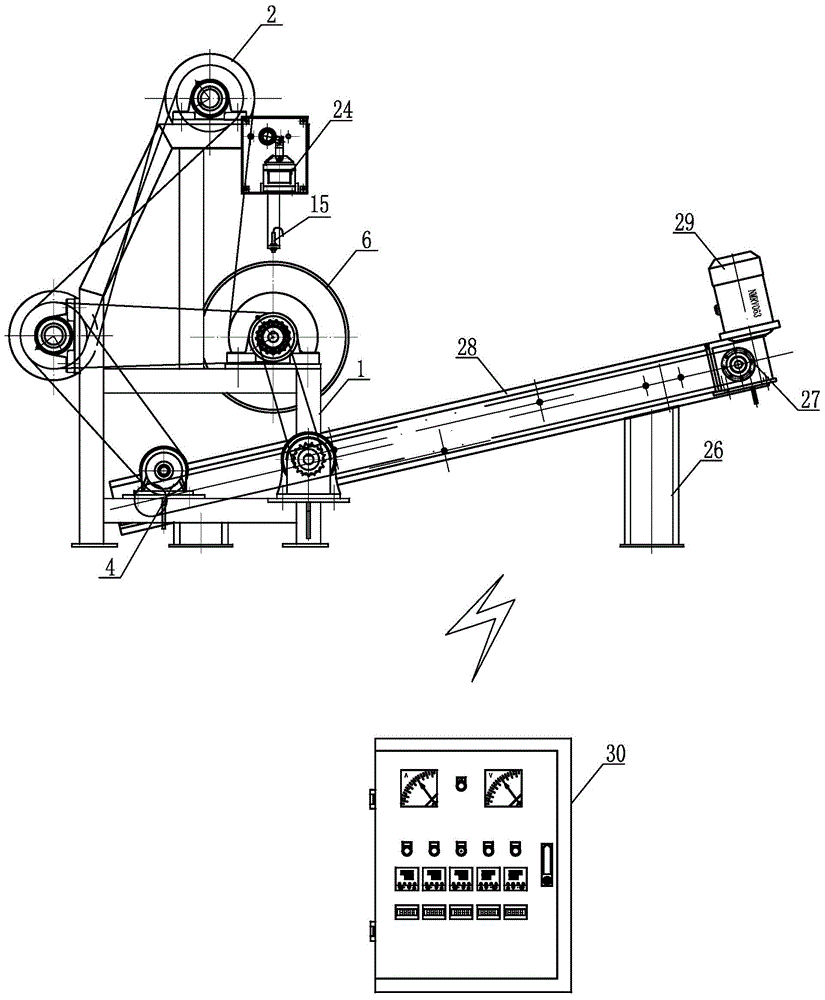

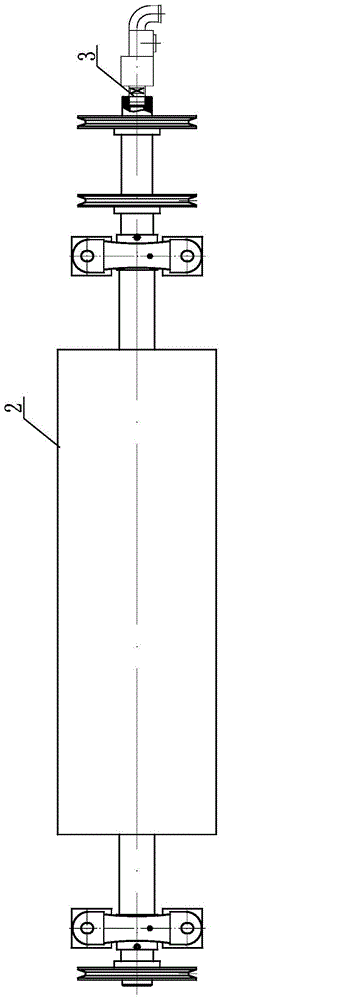

Full-automatic reclaimed rubber cooling film winding machine

ActiveCN104528428AAvoid bouncingEasy to disengageArticle deliveryWebs handlingWinding machineSheet film

The invention discloses a full-automatic reclaimed rubber cooling film winding machine which comprises a film winding machine frame, a conveying roller and a rotating connector. A film roll winding cutting roller is arranged below the conveying roller at the tail end. A film roll holding device is arranged between the conveying roller at the tail end and the film roll winding cutting roller. A finished rubber output device is arranged below the film roll winding cutting device. The conveying roller and the film roll winding cutting roller are connected with roller driving mechanisms respectively. A cutting driving device is arranged on one side of the film roll winding cutting roller. A film roll grabbing device is arranged on the outer surface of the film roll winding cutting roller. The conveying roller is used for conveying and cooling film rolls, a winding cutting roller body is used for carrying out quantifying winding of the film rolls, cutting using of a film cutting knife is convenient, the film roll holding device is used for carrying out holding fixing on film rolls at a conveying end after cutting, film roll going back is avoided, the film roll grabbing device can grab the ends of the cut film rolls which are fixed on the surface of the winding cutting roller body, and accordingly film roll winding can be carried out continuously conveniently. Multiple functions such as cooling, slicing and conveying are integrated.

Owner:JUXIAN DONGSHENG RUBBER

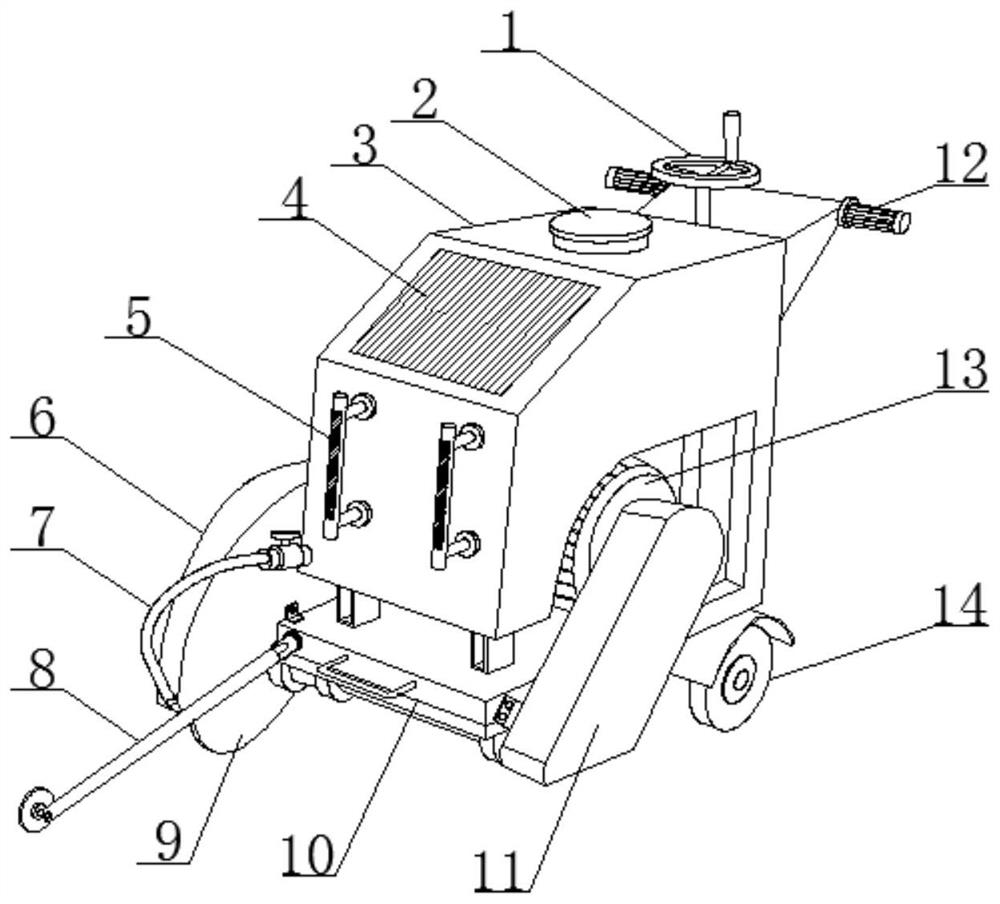

Pavement cutting equipment for building construction

InactiveCN112080998AEasy to viewEasy to moveRoads maintainenceArchitectural engineeringElectric machinery

The invention discloses pavement cutting equipment for building construction. The pavement cutting equipment comprises a bottom machine body and a driving motor; the driving motor is fixedly installedin the middle of the upper end of the bottom machine body; auxiliary roller rods are arranged at the front end of the bottom machine body; rear side rotating wheels are arranged on the two sides of the rear end of the bottom machine body; an outer side rotating mechanism is arranged at the position, located on the bottom machine body, of the outer end of the driving motor; the water liquid position of a water tank shell can be conveniently checked through a liquid level sight gauge composed of observation glass, a fixed outer ring, a hollow pipeline and a fixed short pipe, and the fixed outerring of the liquid level sight gauge is connected to the water tank shell in a welded mode, so that falling is not likely to happen in the using process. In addition, the inside of the water tank shell is through, so that a water source can flow conveniently, when the pavement cutting equipment is used, a U-shaped pipe is composed of the hollow pipe and the fixed short pipe, the observation glasson the outer side of the hollow pipe can be used for well checking, people can be reminded conveniently during the using process, and therefore cutting is more convenient during the using process.

Owner:江苏科建建筑加固有限公司

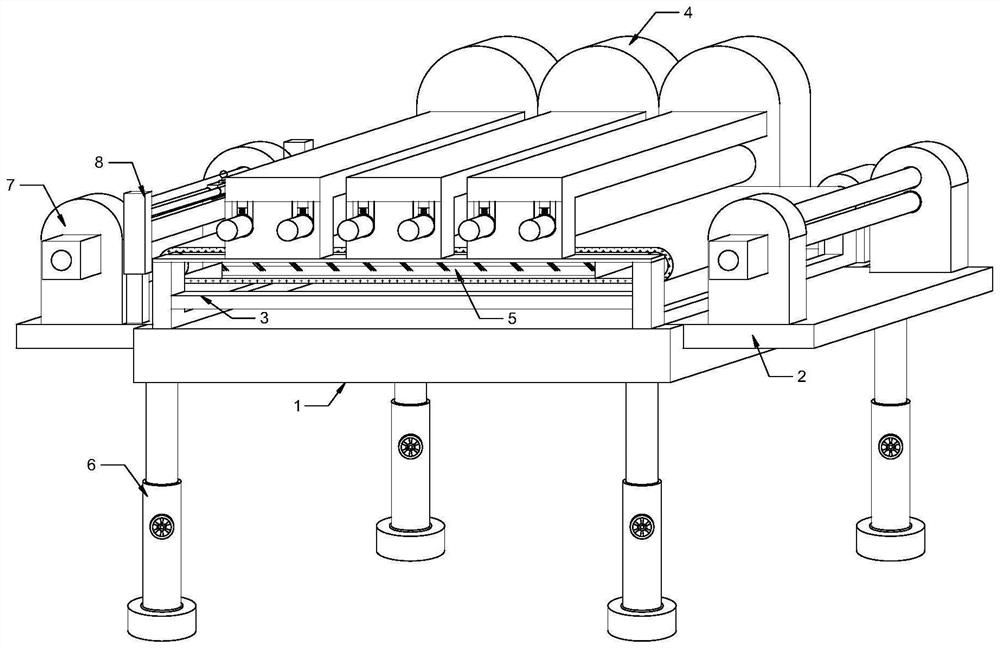

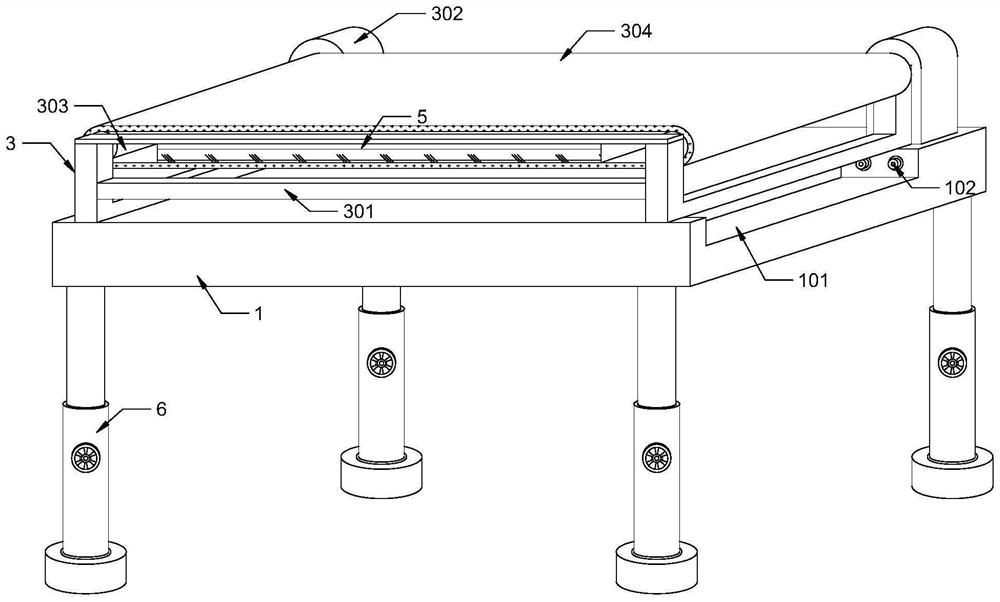

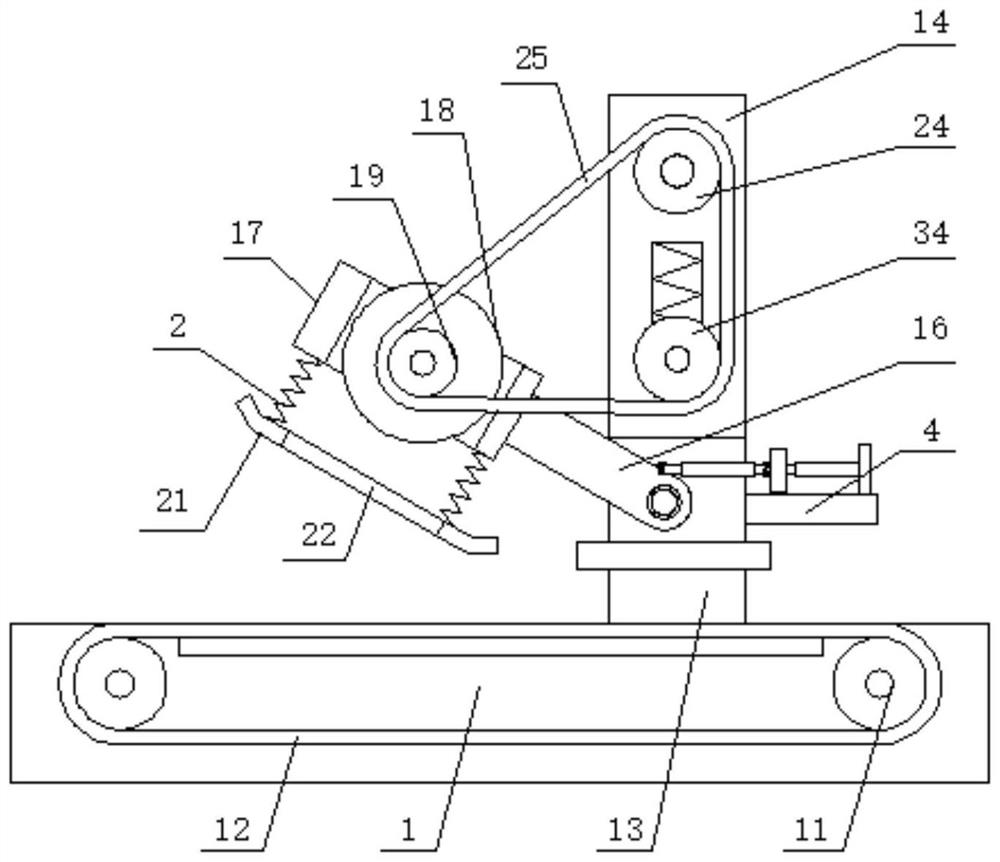

Automatic thin knife longitudinal cutting device for paperboard

ActiveCN111496854AImprove adaptabilityCutting stabilityMetal working apparatusPaperboardStructural engineering

The invention discloses an automatic thin knife longitudinal cutting device for paperboard. The device comprises a rack, wherein conveying rollers are rotatably arranged at two ends of the rack, a conveying belt is rotatably mounted on the surfaces of the conveying rollers, a mounting plate is fixedly mounted at one end of the rack, fixing plates are fixedly connected to the surface of the other side of the mounting plate, an inclined connecting plate is hinged to the surface of one side of each fixing plate through a hinge seat, the other end of each inclined connecting plate is fixedly connected with a mounting frame, the side surface of each mounting frame is rotatably provided with a longitudinal cutter, the shaft end of each longitudinal cutter is fixedly provided with a driven belt wheel, the surface of the other side of each mounting frame is fixedly connected with connecting springs, the other ends of the connecting springs are fixedly provided with auxiliary pressing plates, and the side surfaces of the auxiliary pressing plates are provided with a strip cutting groove. In this way, the convenience and stability of use can be greatly improved, and the safety and high efficiency can be ensured.

Owner:四川宏图风景环保科技有限公司

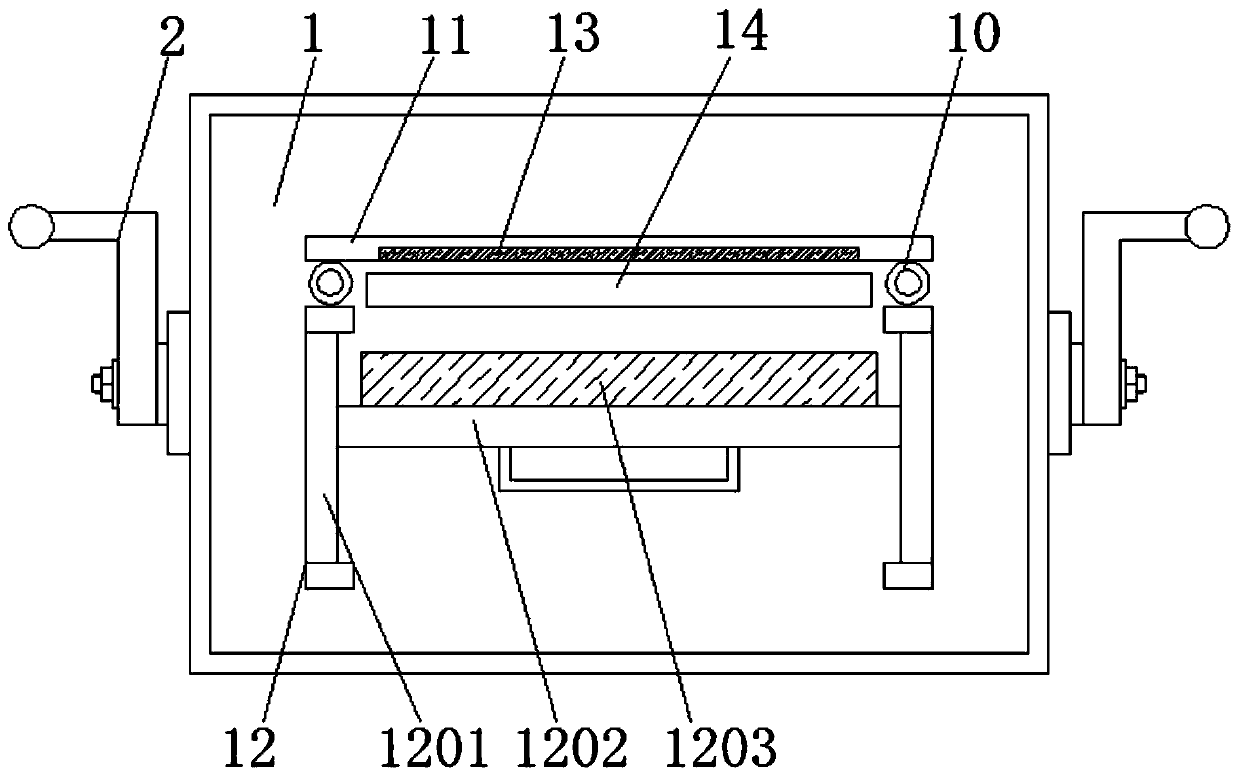

Winding device provided with cutting structure and applied to chemical fiber braid

The invention discloses a winding device provided with a cutting structure and applied to a chemical fiber braid. The winding device comprises a fixed bracket, a telescopic rack and a clamping mechanism; the left and right sides of the fixed bracket are each provided with a rotating handle; bearings are correspondingly installed inside the left and right ends of the fixed bracket; and the inner side of a rotating shaft is connected with a rotary connecting block. Compared with an existing common winding device for the chemical fiber braid, the winding device provided with the cutting structureand applied to the chemical fiber braid integrates winding with cutting, provides conveniences maintaining cut-off of a chemical fiber braid which is quantitatively furled by the device, and also provides conveniences for real-time cutting in an unwinding process of the chemical fiber braid, thus the use convenience and practicability of the winding device are improved; the complexity of windingand cutting of the chemical fiber braid is reduced; meanwhile, the end head of the wound chemical fiber braid can be clamped and limited so that a user can conveniently and quickly lock the end head of the chemical fiber braid, thereby providing conveniences for winding and unwinding use of the chemical fiber braid inside the device.

Owner:宁远蓝海化纤有限公司

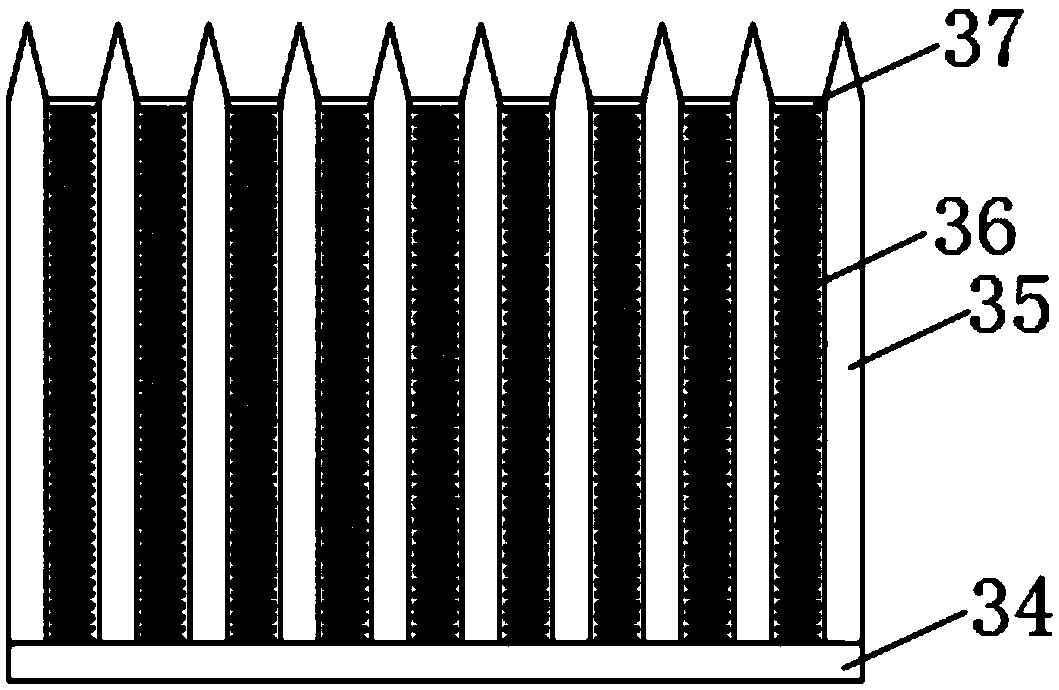

Longitudinal slitting machine for bamboo shoots

InactiveCN109093668AEasy to cut and useEasy to placeMetal working apparatusSlice thicknessBamboo shoot

The invention discloses a longitudinal slitting machine for bamboo shoots. The longitudinal slitting machine comprises a slicing mechanism and a receiving mechanism. The receiving mechanism is arranged below the slicing mechanism. According to the longitudinal slitting machine for the bamboo shoots, the structure is compact, and cutting and using of the bamboo shoots are facilitated; by arrangingthe receiving mechanism, under action of a first air cylinder and a flat paving plate, bamboo shoot slices after cutting are placed on a collecting plate advantageously, the thickness of the bamboo shoot slices can be controlled through the flat paving plate, manual paving is not required, the labor intensity of workers is reduced, and automatic paving is realized; by arranging the slicing mechanism, one-knife shaping is facilitated through cutting blades and anti-plugging plates, and the cutting efficiency is greatly improved; and the slice thickness is controlled by different cutting knives,the time and effort are saved, and automatic cutting is realized.

Owner:胡笑鸣

Electric wire and cable rotating mold convenient to maintain

ActiveCN112750575AGuaranteed work efficiencyConducive to extrusion and straighteningCable/conductor manufacturePollutionElectric wire

The invention provides an electric wire and cable rotating mold convenient to maintain; the mold comprises a rack, a longitudinally arranged support frame is in bolted connection with the right upper side of the rack, a longitudinally arranged wire distributing disc is in bolted connection with the upper end of the support frame, and wire inlet holes are formed in the periphery of the interior of the wire distributing disc; a longitudinally-arranged support is in bolted connection with the upper left side of the rack, a transversely-arranged servo motor is in bolted connection with the middle of the lower right side of the support, and an output shaft of the servo motor penetrates through the interior of the support and is in key connection with a driving belt wheel. Through the arrangement of an impurity collecting hopper, a flow guide pipe, an impurity collecting box, an observation piece, a cleaning plate, a dust cleaning plate and a filtering separation net, impurities and dust can be collected into the impurity collecting box through the flow guide pipe by the impurity collecting hopper, and then large impurities and dust are separated and filtered through the filtering separation net; and finally, the cleaning plate and the dust cleaning plate can be taken down for separation and cleaning, operation is convenient, and environmental pollution is avoided.

Owner:JIANGXI ELECTRIC VOCATIONAL & TECHN COLLEGE +1

Preparation method for soft powder metal composite coiled material

Provided is a preparation method for a soft powder metal composite coiled material. The soft powder metal composite coiled material includes a high molecular elastomeric polymer and metal powder, wherein the particle size of the metal powder is less than 1 mm, and the high molecular elastomeric polymer includes rubber, plastic, polyurethane, bitumen, etc. The metal powder is mixed and added into a plurality of gaps existing in the stereoscopic net structure of the high molecular elastomeric polymer which is pressed into the needed soft powder metal composite coiled material in order to meet the requirements of people from different sectors and industries.

Owner:马明

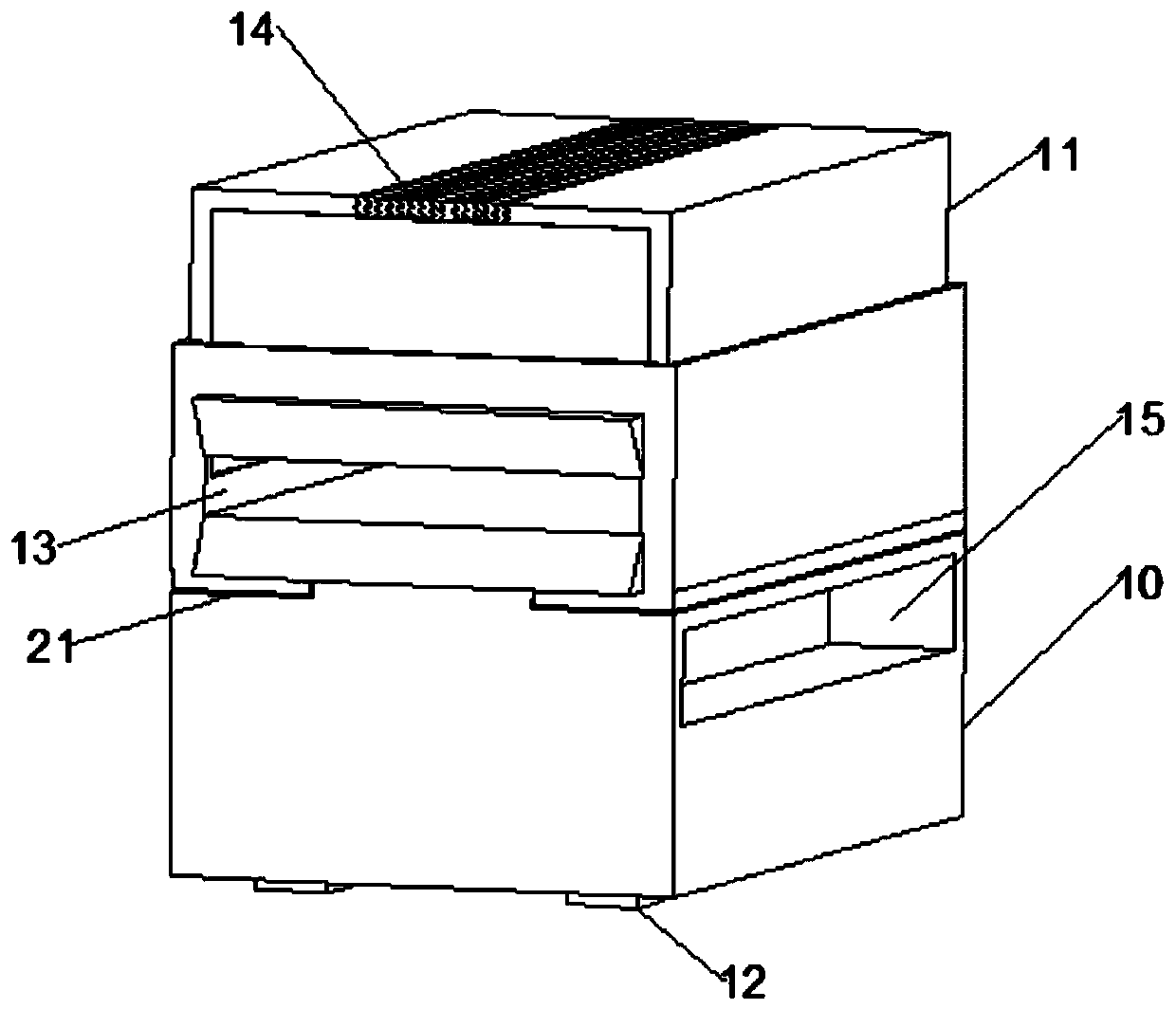

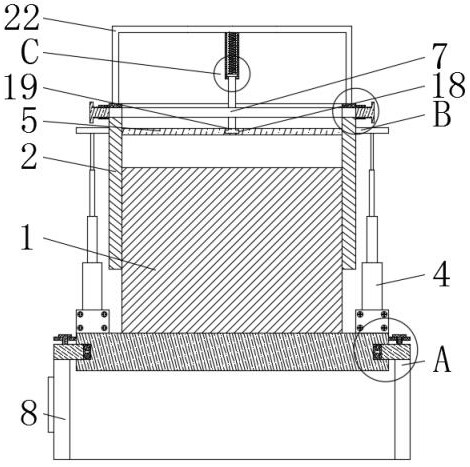

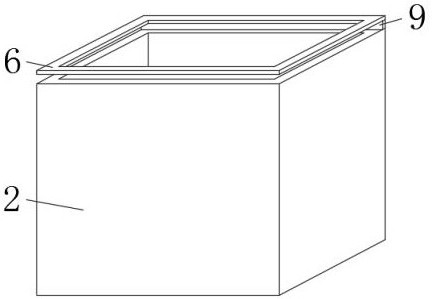

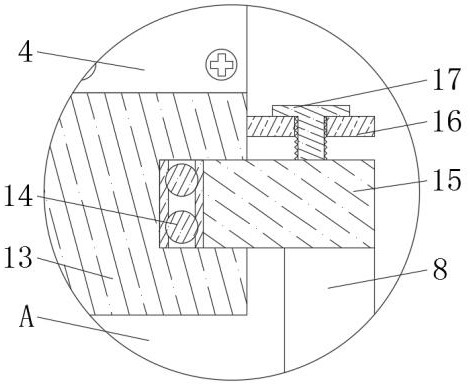

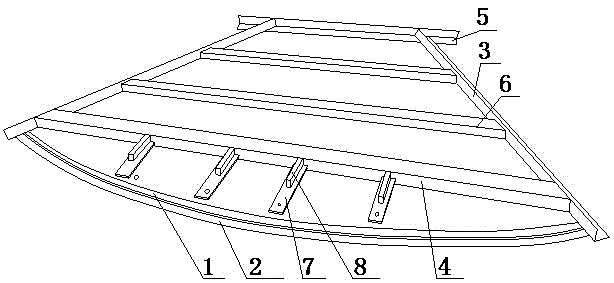

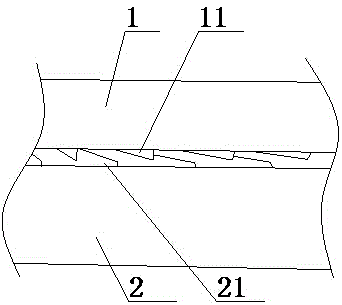

Cutting device for foam sandwich plate

InactiveCN110497459AEasy to cut and useObserve the cutting situationMetal working apparatusDrive wheelSandwich board

The invention relates to the technical field of production of foam plastics, and discloses a cutting device for a foam sandwich plate. The cutting device comprises a box body, a plate inlet, a scrap outlet and cutting knives, wherein a group of cutting knives are arranged in the middle of the rear side of a cutting channel; two groups of pulling rods are symmetrically arranged on the left side andthe right side of the bottom parts of the cutting knives; pulling plates are mounted on the upper end and the lower end of the corresponding pulling rod; a driven wheel is mounted inwards in the middle of the corresponding pulling rod through a corresponding connecting rod; the lower side of the corresponding driven wheel is meshed with a corresponding driving wheel; the center of the corresponding driving wheel is rotatably connected with a rotating motor inwards; connecting plates are arranged on the left side and the right side of the cutting channel; a horizontal nesting plate is mountedon the outer side of the corresponding connecting plate in a sleeving manner; the nesting plates are connected with the connecting plates in a sliding manner; the bottom end of the corresponding nesting plate is connected with a movable tank of which one end is fixed to the inner wall of the box body in a sliding manner; multiple groups of discharging holes are formed in the middle of the corresponding connecting plate at equal distances from front to back; and a scrap receiving plate is arranged under the discharging holes. The cutting device disclosed by the invention has the advantages of being wide in application range, quick in automatic operation, high in cutting efficiency and beneficial for popularization and application.

Owner:孙帅

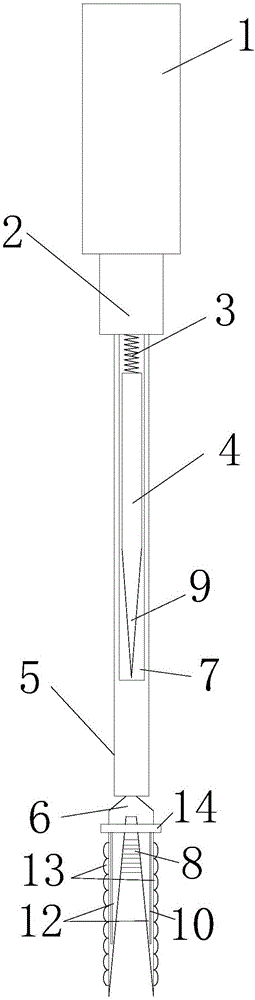

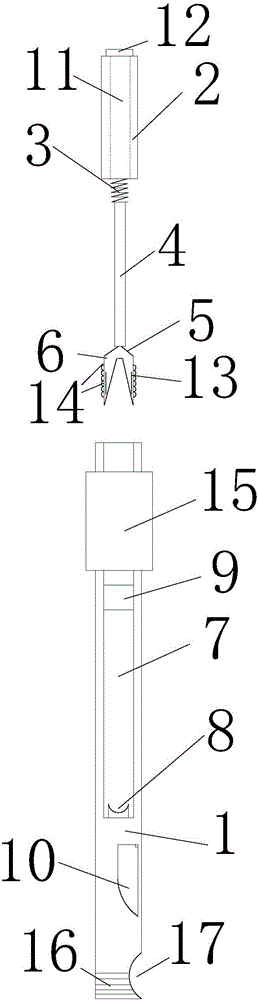

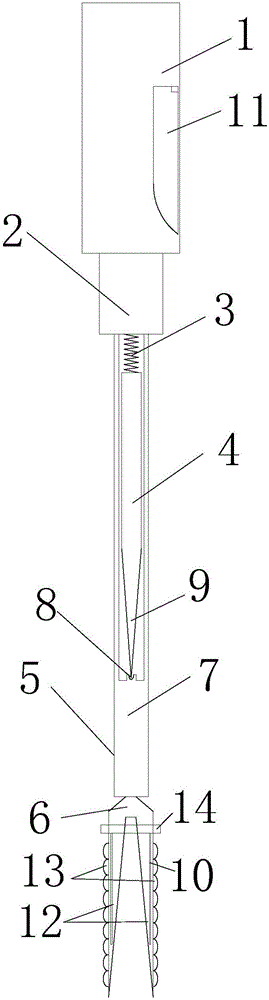

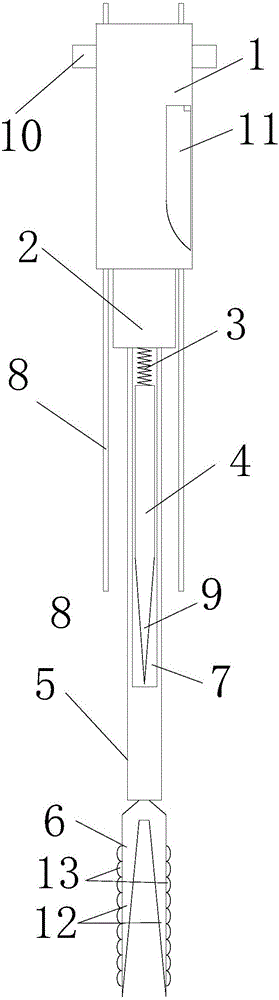

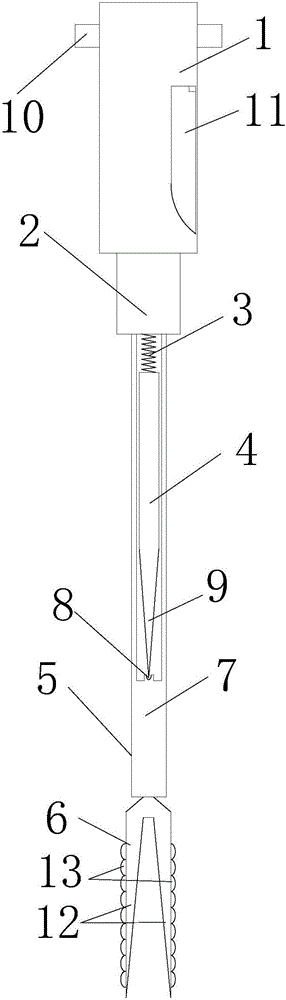

High-strength fork with function of cutter

The invention discloses a high-strength fork with a function of a cutter. The cutter is rotatably and movably connected with an end rod, and the cutter can be contained in a plane enclosed by the upper top surface of the end rod; a buffer block is arranged at a free end of the end rod, a spring is arranged in the buffer block, the bottom of the spring is connected with a needle tag, the fork rod can be movably inserted into and pulled out from the buffer block, a cavity is formed in the fork rod, the needle tag can be contained in the cavity of the fork rod, a fork head is arranged on the outer wall of the lower end of the fork rod, the fork head comprises fork blades at the two sides, the fork blades at the two sides are combined on the outer wall of the lower end of the fork rod, a plurality of sawteeth convenient for cutting food are arranged on the outer side surface of each fork blade, multiple reinforcing ribs are arranged between the two fork blades, multiple reinforcing ribs are parallel to one another, and the lowest position of the reinforcing ribs is higher than the vertical central position of the fork blades.

Owner:祝敏

Cutting device for konjac forming

PendingCN112606056AAdjustable spacingTo prevent the influence of re-cutting and useMetal working apparatusThreaded pipeKnife blades

The invention discloses a cutting device for konjac forming. The cutting device comprises a placing table, wherein a lifting box is installed on the side wall of the placing table in a sleeving mode. The cutting device has the beneficial effects that an adjusting knife rest is adopted, when the distance between a plurality of sets of blades needs to be adjusted, a plurality of sets of sliding blocks are adjusted to drive the plurality of sets of blades to move; when the plurality of sets of blades move to the expected position, a plurality of sets of fastening threaded pipes are rotated clockwise and anticlockwise in the reverse direction; when the plurality of sets of fastening threaded pipes are in close contact with the side wall of the adjusting knife rest, the movement is stopped; when the longitudinal cutting angle of the plurality of sets of blades needs to be adjusted, two sets of fastening bolts are rotated anticlockwise; when one end of each of the two sets of fastening bolts is separated from a mounting ring, an I-shaped shaft is rotated; when the plurality of sets of blades move to the expected position, the two sets of fastening bolts are rotated clockwise; and when one end of each of the two sets of fastening bolts are in contact with the mounting ring, the movement is stopped, the distance between the plurality of sets of blades can be adjusted through the arranged adjusting knife rest, and meanwhile, the longitudinal angle of cutting can be adjusted.

Owner:郑州顺天缘食品有限公司

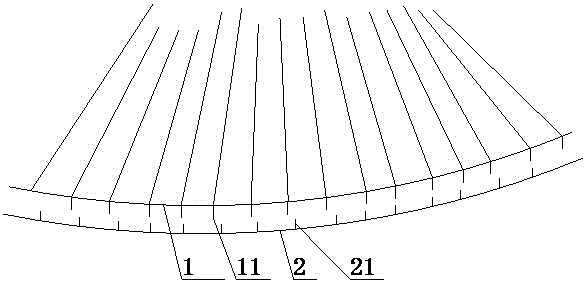

Multi-specification cloth crumpling die plate

InactiveCN105484009ASatisfied with creasingImprove processing efficiencyTextile shapingMechanical engineering

A multi-specification cloth crumpling die plate comprises a crumpling mechanism. The crumpling mechanism is composed of an upper die crumpling plate and a lower die crumpling plate. The upper die crumpling plate is arranged at the top of the lower die crumpling plate, the cross section of the upper die crumpling plate and the cross section of the lower die crumpling plate are both in an arc shape, a gap is formed between the upper die crumpling plate and the lower die crumpling plate, a plurality of upper crumpling bars are arranged on the lower surface of the upper die crumpling plate and evenly distributed, a plurality of lower crumpling bars matched with the upper crumpling bars are arranged on the upper surface of the lower die crumpling plate and evenly distributed, the upper crumpling bars and the lower crumpling bars are distributed in a staggered mode, and the upper die crumpling plate and the lower die crumpling plate are both made of stainless steel. A fixing frame is arranged at the top of the upper die crumpling plate. According to the multi-specification cloth crumpling die plate, cloth is crumpled through the cooperation of the crumpling bars distributed between the upper die crumpling plate and the lower die crumpling plate in a tooth shape, the processing efficiency is high, the requirement for crumpling processing of cloth of various specifications can be met, the processing efficiency can be improved, and the production cost can be lowered; the multi-specification cloth crumpling die plate is worthy of wide popularization.

Owner:麦永强 +1

Extending flattening device applied to textile machine cloth rolling

InactiveCN114701898AConvenience for subsequent useImprove flattening effectArticle deliveryWebs handlingTextile technologyElectric machinery

The invention discloses a flattening device applied to cloth rolling and stretching of a textile machine, and relates to the technical field of textile. Comprising an operation table, a pull-in mechanism, a conduction mechanism, a flattening mechanism, a pressure-resistant block, supporting legs, a pull-out mechanism and a cutting mechanism, the supporting legs are fixedly arranged at the bottom of the operation table, the conduction mechanism is fixedly arranged at the top of the operation table, the pressure-resistant block is fixedly arranged in the conduction mechanism, and the flattening mechanism is movably arranged at the top of the conduction mechanism. A driving motor is arranged to effectively drive a pressing roller to operate, the distance between the pressing roller and a conveying belt is adjusted and controlled through the effect of a connecting spring, then the stretching cloth placed on the conveying belt is flattened, meanwhile, the three flattening mechanisms are arranged at the top of a conduction mechanism at equal intervals, the flattening distance of the conduction mechanism is prolonged, and the flattening efficiency is improved. And the flattening effect on cloth stretching is effectively improved, follow-up use of cloth is facilitated, and then the usability of the device is improved.

Owner:浙江笑谈科技有限公司

Easy-to-cut safety adhesive tape

InactiveCN1417279AEasy to cutEasy to tearFilm/foil adhesivesLayered productsPlastic filmPhysical property

The easy-to-cut safe adhesive tape includes a substrate layer, a hard resin layer, an adhesive layer and a non-adhesive layer. The substrate layer is plastic film, the hard resin layer is applied to the substrate layer to regulate structure property, the adhesive layer is applied to the bottom surface of the substrate layer and the non-adhesive layer is applied to the surface of the hard resin layer for peeling effect. With the hard resin layer to regulate the physical property, the adhesive tape is easy to cut and safe.

Owner:林惠珠

Clamping and cutting chopstick

The invention discloses a multifunctional clamping and cutting chopstick. A cutter is rotationally and movably connected on the rod body and can be contained in a plane formed by encircling of the upper top surface of the rod body; a spring is connected to the bottom of a fixed arm; a forked rod is arranged at the bottom of the spring; a fork head is arranged on the outer wall at the lower end of the forked rod; a rib is arranged on the fork blade on each side; the ribs extend along the fork blade length direction; a plurality of sawteeth convenient for food cutting are formed in the outer side face of the forked blade on each side; a cavity is formed in the upper part of the rod body; a buffer groove is formed in the inner wall of the bottom of the cavity; the end of the fork blade can stretch into the buffer groove; a clamp is arranged on the inner wall of the middle of the cavity of the rod body; a forked rod penetrates through the clamp and is locked and movably connected by the clamp; a wrapping layer is coated on the upper part of the rod body; a transverse anti-drop bulge is formed on the lower end of the rod body and is spiral; and an inner notch is formed in the side of the lower end of the rod body and positioned on one side of the transverse anti-drop bulge.

Owner:周言鑫

Fork with cutter and antiskid function

The invention discloses a fork with a cutter and an antiskid function. The cutter can be rotationally and movably connected to an end rod, and the cutter can be contained in the plane defined by the upper top face of the end rod. A buffer block is arranged at the free end of the end rod, a spring is arranged in the buffer block, the bottom of the spring is connected with a needle stick, a cavity is formed in a fork rod, the needle stick can be contained in the cavity of the fork rod, a clamping groove is formed in the inner wall of the lower end of the fork rod, and a needle head at the end of the needle stick can be inserted into the clamping groove for fixation. A fork head is arranged on the outer wall of the lower end of the fork rod and comprises two side fork blades, the ends of the two side fork blades are combined on the outer wall of the lower end of the fork rod, a flange is arranged on each fork blade, the flanges stretch in the length directions of the fork blades, multiple sawteeth are arranged on the outer side face of each fork blade, the sawteeth on the two sides are symmetrically arranged, a circle of buffer cushion is arranged on the outer edge faces of the fork blades on the two sides, the position of the buffer cushion is higher than the sawteeth on the topmost portions, and the buffer cushion is made of edible resin materials.

Owner:王伟民

Portable fork with functions of cutter

The invention discloses a portable fork with the functions of a cutter. The portable fork is characterized in that hooks are arranged on the rear side of an end rod; a cutter can be connected to the end rod in a rotary and movable manner and can be stored in a plane formed by encircling of the upper top surface of the end rod; a buffer block is arranged at the free end of the end rod; a spring is arranged in the buffer block; a prod is connected at the bottom of the spring; a through hole is formed in each of the two sides of the end rod; a chopstick is inserted into the through hole; the parts, extending out of the through holes, of the two chopsticks are arranged at the two sides of the buffer block; a fork rod can be movably inserted into or pulled out of the buffer block; a cavity is formed in the fork rod; the prod can be held in the cavity of the fork rod; a forkhead is arranged on the outer wall of the lower end of the forkhead and comprises fork blades at the two sides; the ends of the fork blades at the two sides are combined on the outer wall of the lower end of the fork rod; a plurality of sawteeth convenient for cutting food are arranged on the outer side of each fork blade.

Owner:祝敏

Full-automatic nozzle cap film sealing system and film sealing method thereof

PendingCN114313441AFully automatic sealingFully automatic usabilityWrapping material feeding apparatusConveyor wrappingThin membraneStructural engineering

The full-automatic nozzle cap film sealing system comprises a bottom metal frame and a discharging film frame, the discharging film frame is fixedly installed on the left side of the upper end of the bottom metal frame, and an adjusting pressing device is arranged on the inner side of the right end of the discharging film frame; a first limiting roller frame is arranged on the portion, located on the bottom metal frame, of the right side of the discharging film frame, a second limiting roller frame is arranged on the portion, located on the bottom metal frame, of the right side of the first limiting roller frame, and a nozzle cap film sealing device is arranged on the portion, located on the bottom metal frame, of the right side of the second limiting roller frame. And a third limiting roller frame is arranged on the portion, located on the bottom metal frame, of the right side of the nozzle cover film sealing device. Through the arrangement of the bottom metal frame, the discharging film frame, the adjusting pressing device, the first limiting roller frame, the second limiting roller frame, the nozzle cover film sealing device and the rotary cutter structure, full-automatic film sealing and shearing can be achieved; and in addition, automatic shearing and blanking can be carried out for use.

Owner:杭州环申新材料科技股份有限公司

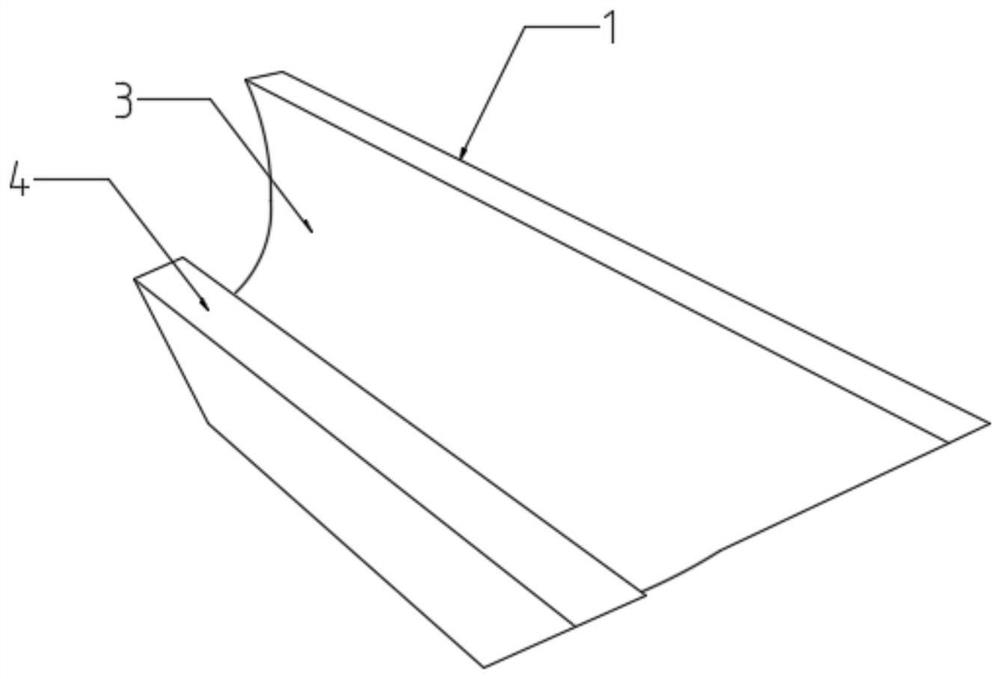

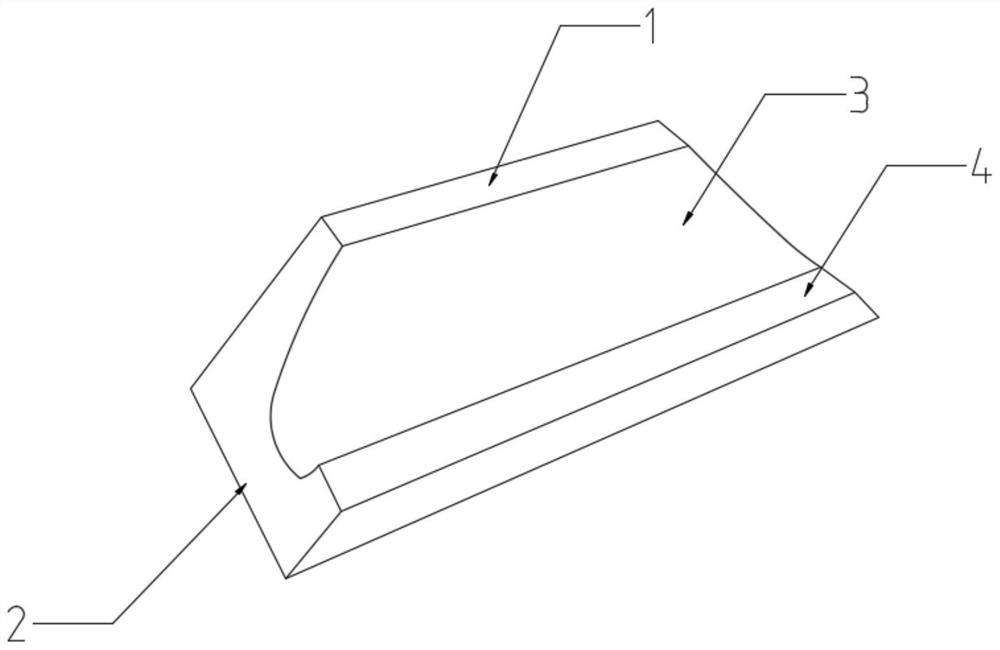

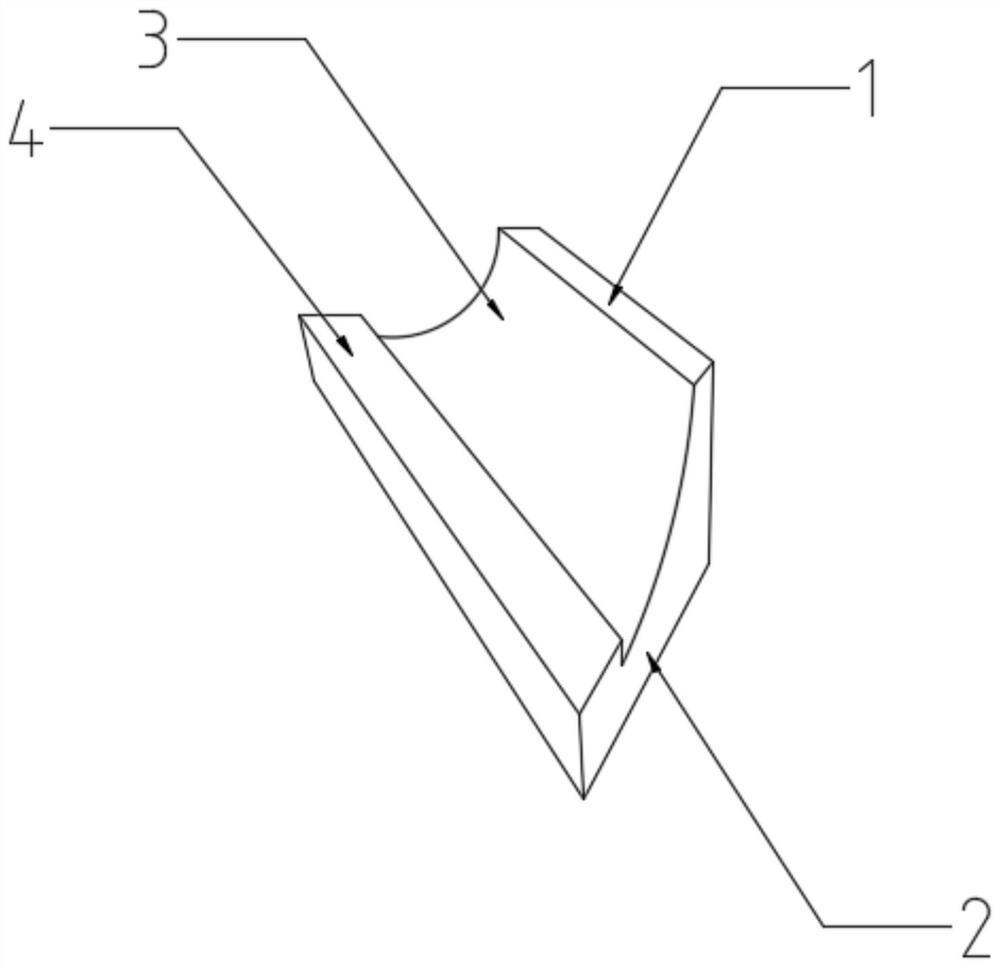

Lineation auxiliary device for cutting

InactiveCN112405486AEffective lineEasy to cut and useOther workshop equipmentIsosceles trapezoidStructural engineering

The invention discloses a lineation auxiliary device for cutting. The lineation auxiliary device comprises a device body. The device body is of an integrated structure. The device body comprises a first side face and a second side face. The first side face is of an isosceles trapezoid structure. The second side face is of a rectangular structure. The lower bottom of the first side face is vertically connected to one long side of the second side face. The first side face and the second side face are connected to form an arc-shaped inclined face. A limiting piece is arranged at one edge of the first side face or the second side face. The limiting piece is of an isosceles trapezoid structure. The outer side face of the limiting piece is flush with one outer side face of the first side face orthe second side face. A limiting groove is formed in the arc-shaped inclined face. The lineation auxiliary device has the beneficial effects that lineation can be effectively conducted on building materials, and cutting and using are convenient; and multiple building materials can be treated, and the lineation auxiliary device is convenient to use, novel in design and capable of being applied andpopularized in a large area.

Owner:黄永杰

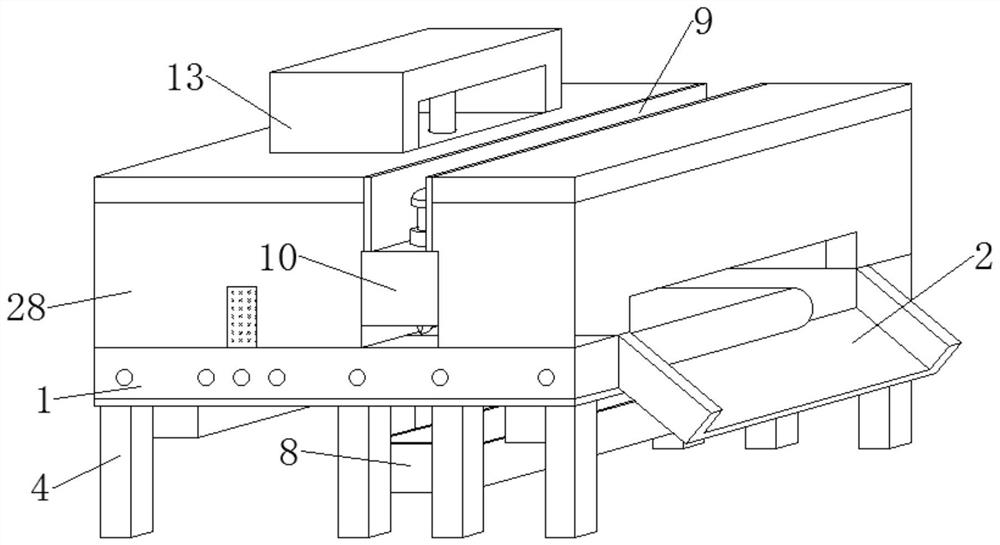

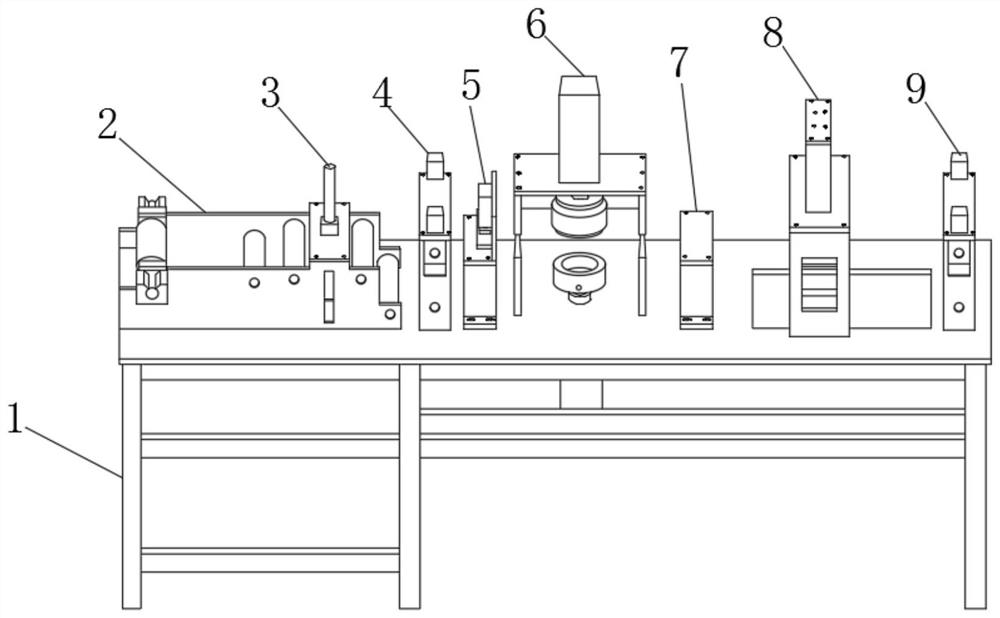

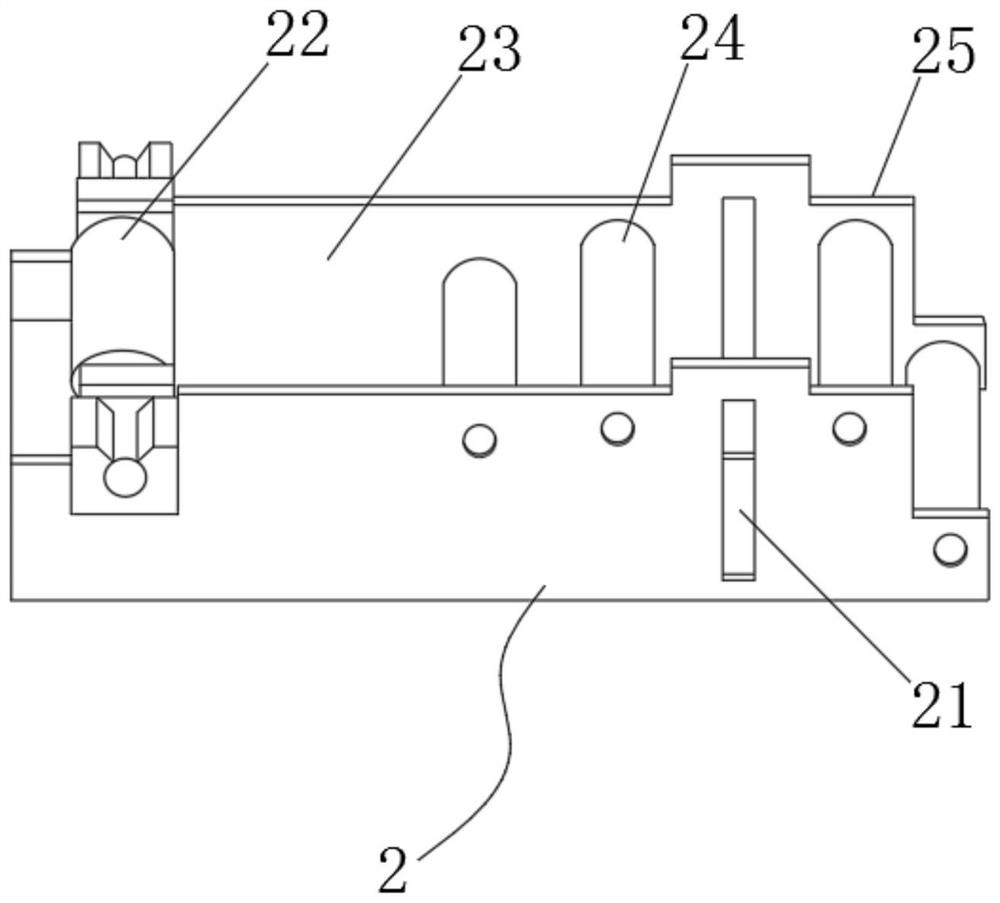

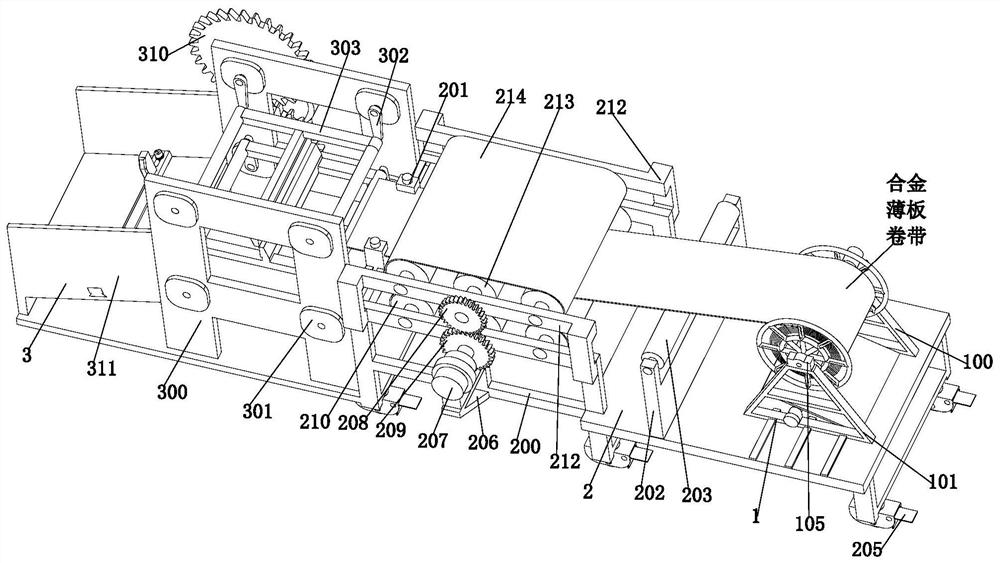

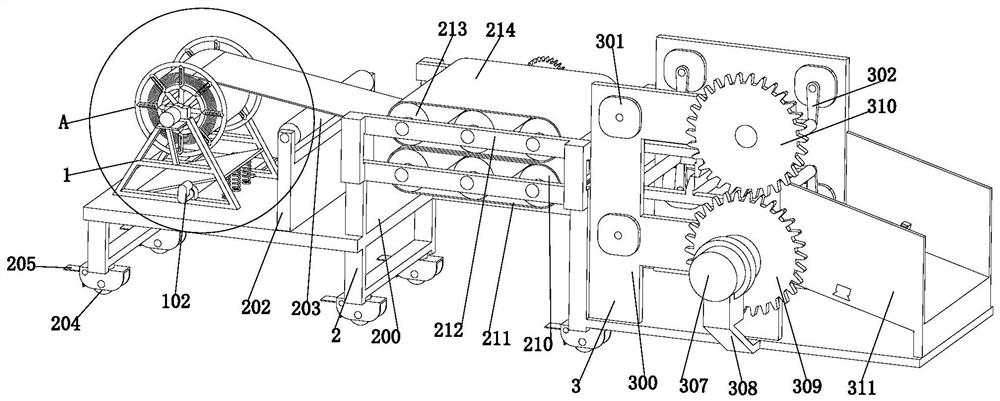

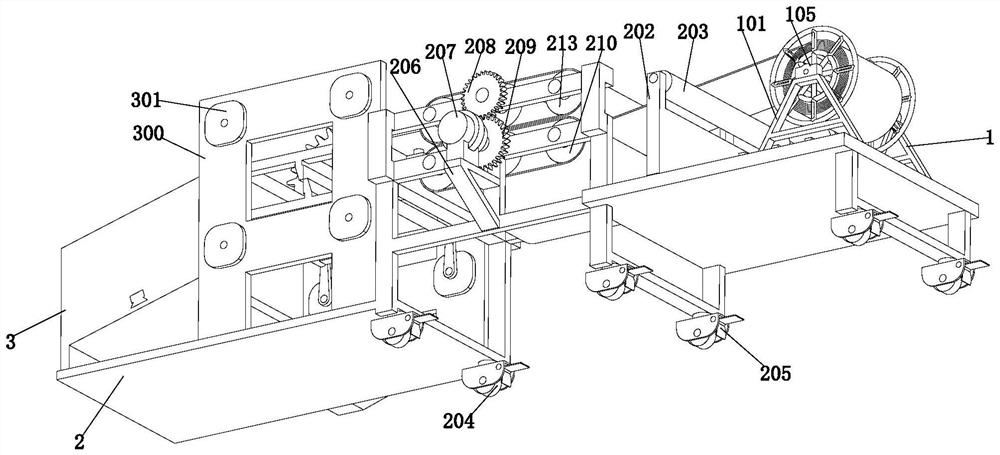

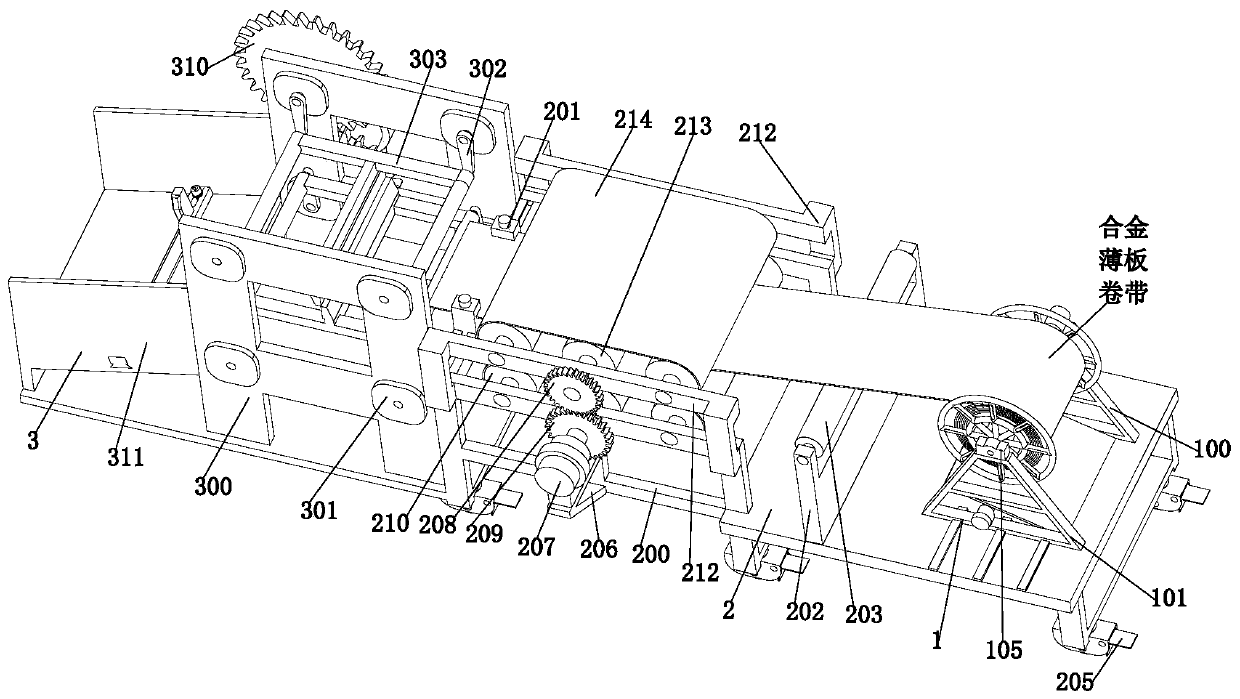

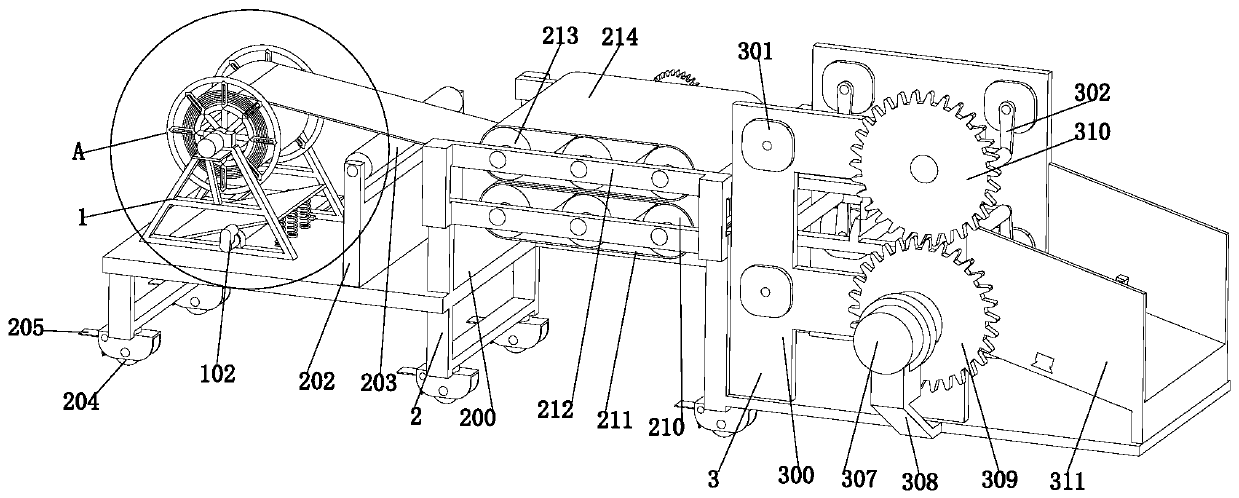

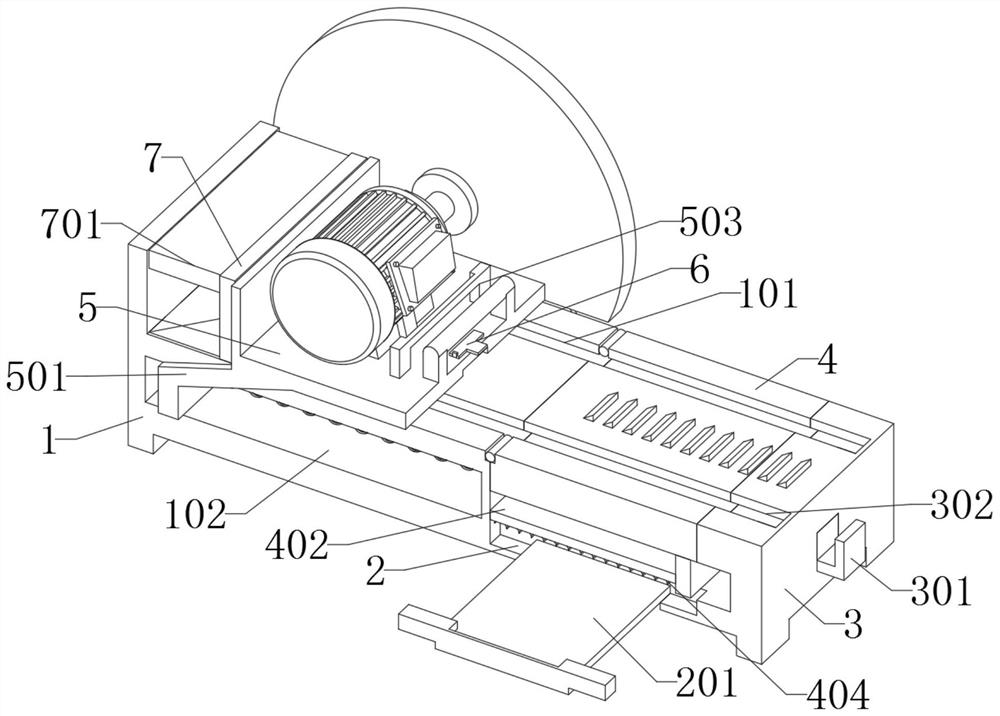

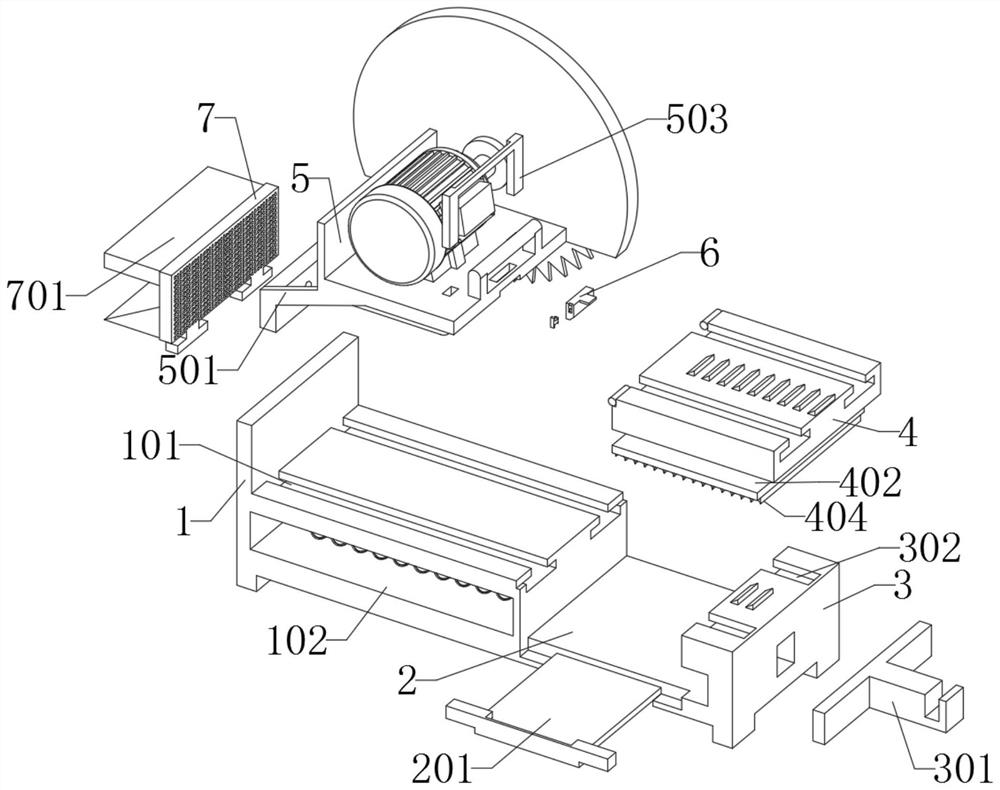

A shearing machine for the production and manufacture of alloy saw blades

ActiveCN111112719BPlay a supporting roleQuick cutShearing machinesShearing machine accessoriesThin slabAlloy

The invention provides producing, manufacturing and cutting machinery for alloy saw blades. The machinery comprises a winding mechanism, a conveying mechanism and a cutting mechanism; the winding mechanism is mounted on the conveying mechanism; the cutting mechanism is arranged on the conveying mechanism; and the conveying mechanism is arranged between the winding mechanism and the cutting mechanism. By the aid of the machinery, the problems that for current linear cutting of alloy sheets, the alloy sheets are mostly cut off manually by the aid of manual cutting machines, the manual cutting machines are inapplicable to efficient linear cutting of the alloy sheets and are very strenuous to operate, burrs are produced at cuts easily, and the manual cutting machines are inapplicable to large-scale low-cost production and manufacturing can be solved.

Owner:江苏风力士智能科技有限公司

A cardboard automatic thin knife slitting device

ActiveCN111496854BImprove adaptabilityCutting stabilityMetal working apparatusCardboardConveyor belt

Owner:四川宏图风景环保科技有限公司

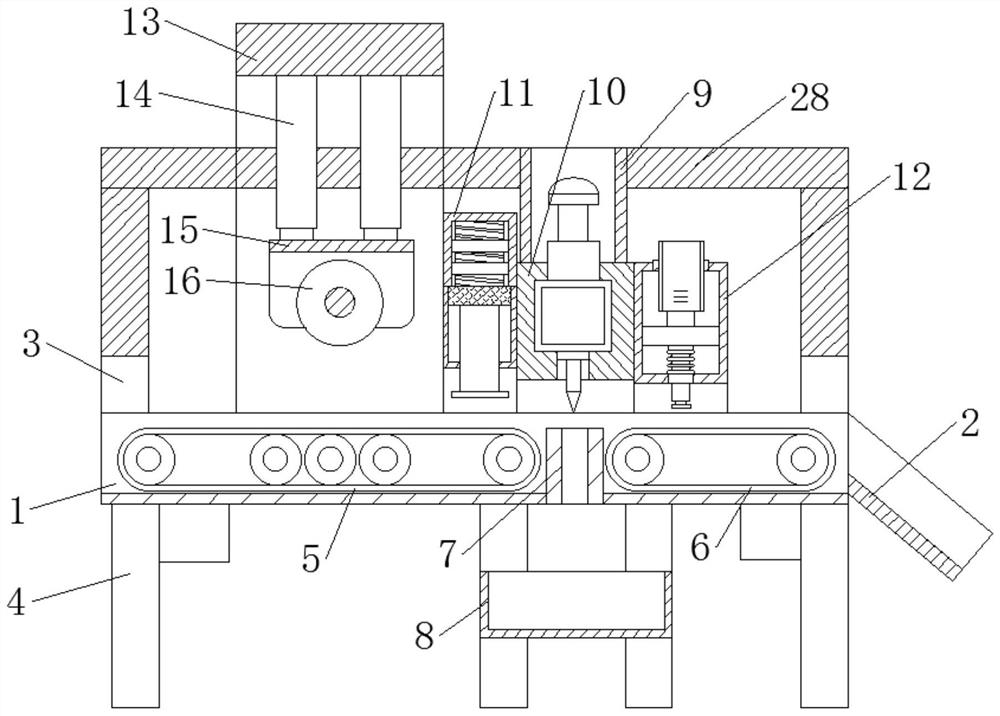

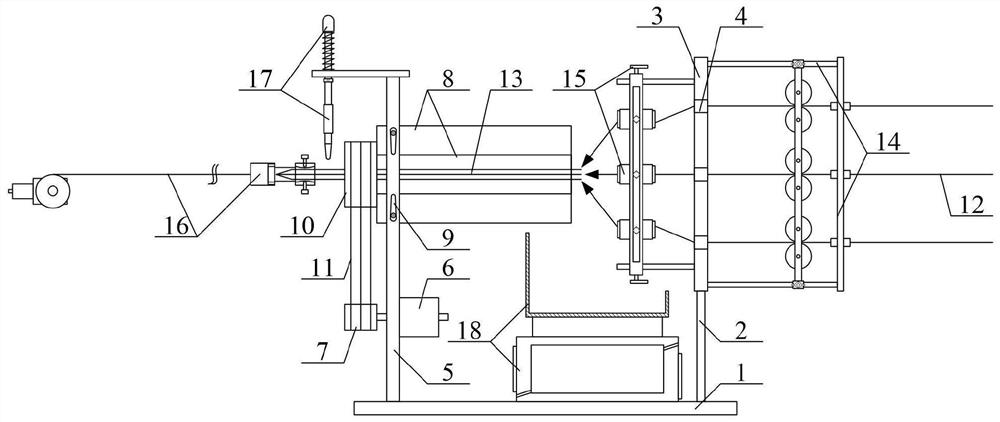

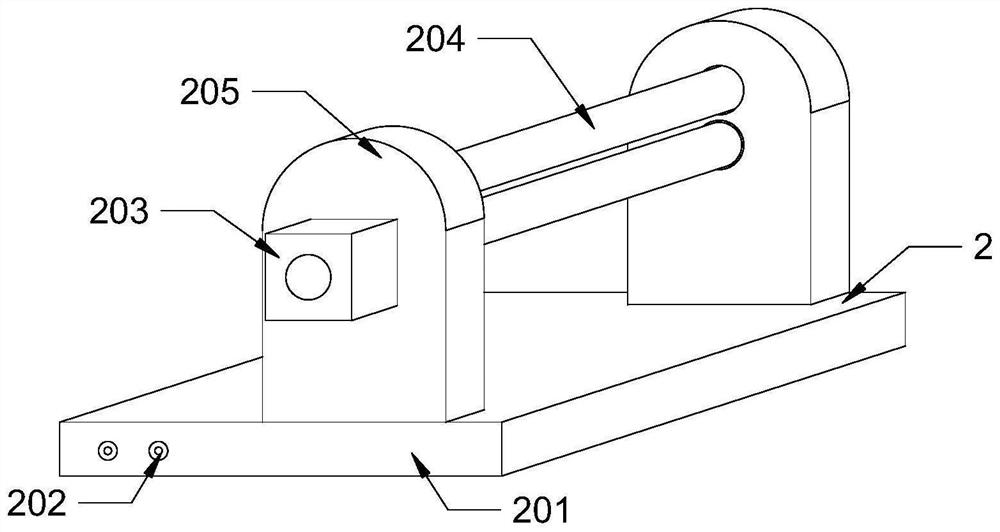

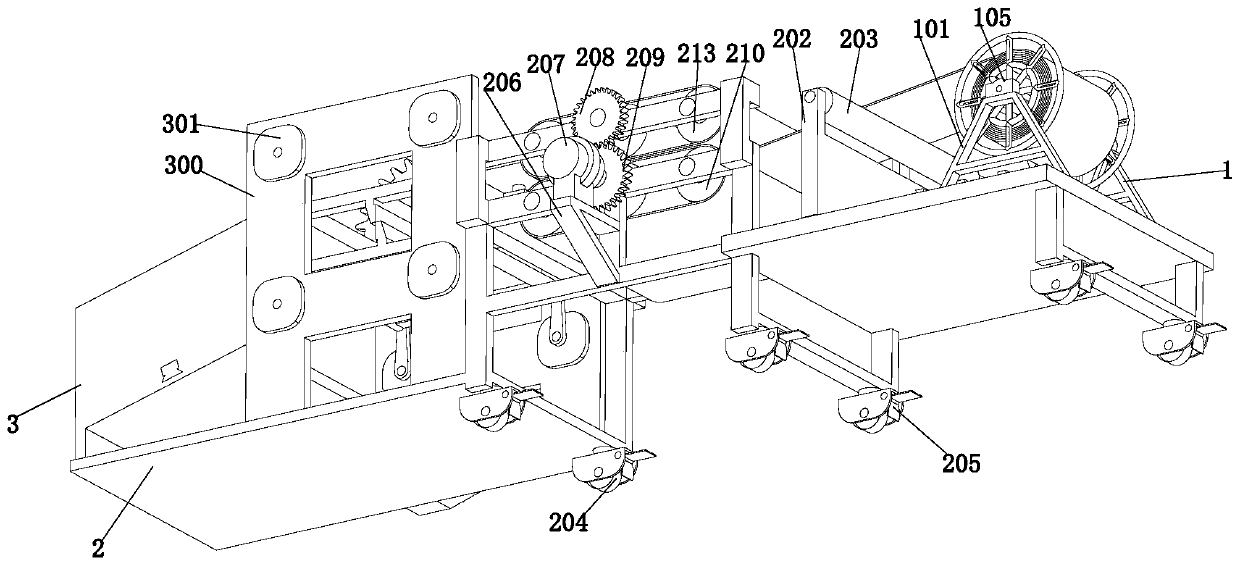

Producing, manufacturing and cutting machinery for alloy saw blades

ActiveCN111112719APlay a supporting roleQuick cutShearing machinesShearing machine accessoriesAlloyMechanical engineering

The invention provides producing, manufacturing and cutting machinery for alloy saw blades. The machinery comprises a winding mechanism, a conveying mechanism and a cutting mechanism; the winding mechanism is mounted on the conveying mechanism; the cutting mechanism is arranged on the conveying mechanism; and the conveying mechanism is arranged between the winding mechanism and the cutting mechanism. By the aid of the machinery, the problems that for current linear cutting of alloy sheets, the alloy sheets are mostly cut off manually by the aid of manual cutting machines, the manual cutting machines are inapplicable to efficient linear cutting of the alloy sheets and are very strenuous to operate, burrs are produced at cuts easily, and the manual cutting machines are inapplicable to large-scale low-cost production and manufacturing can be solved.

Owner:江苏风力士智能科技有限公司

Fork with knife function

The invention discloses a fork with a knife function. A hook is arranged on the rear side face of an end rod, and a knife can rotate to be movably connected to the end rod and can be stored in a plane defined by the upper top face of the end rod. A buffer block is arranged at the free end of the end rod, a spring is arranged in the buffer block, a needle stick is connected to the bottom of the spring, a fork rod can be movably inserted into or pulled out of the buffer block, a cavity is formed in the fork rod, the needle stick can be contained in the cavity of the fork rod, a clamping groove is formed in the inner wall of the lower end of the fork rod, a needle head at the end of the needle stick can be inserted in the clamping groove to be fixed, and a fork head is arranged on the outer wall of the lower end of the fork rod. The fork head comprises fork blades on the two sides, the ends of the fork blades on the two sides are combined on the outer wall of the lower end of the fork rod, a plurality of sawteeth facilitating food cutting are arranged on the outer side face of each fork blade, the sawteeth on the two sides are symmetrically arranged, and no gap exists between every two adjacent sawteeth on each side.

Owner:王伟民

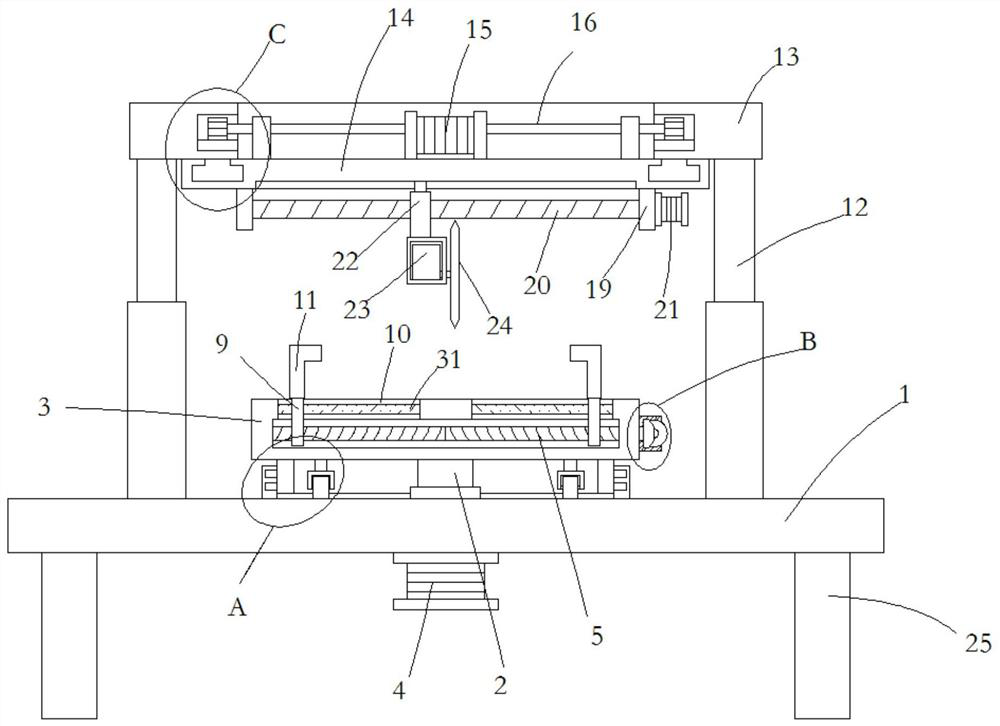

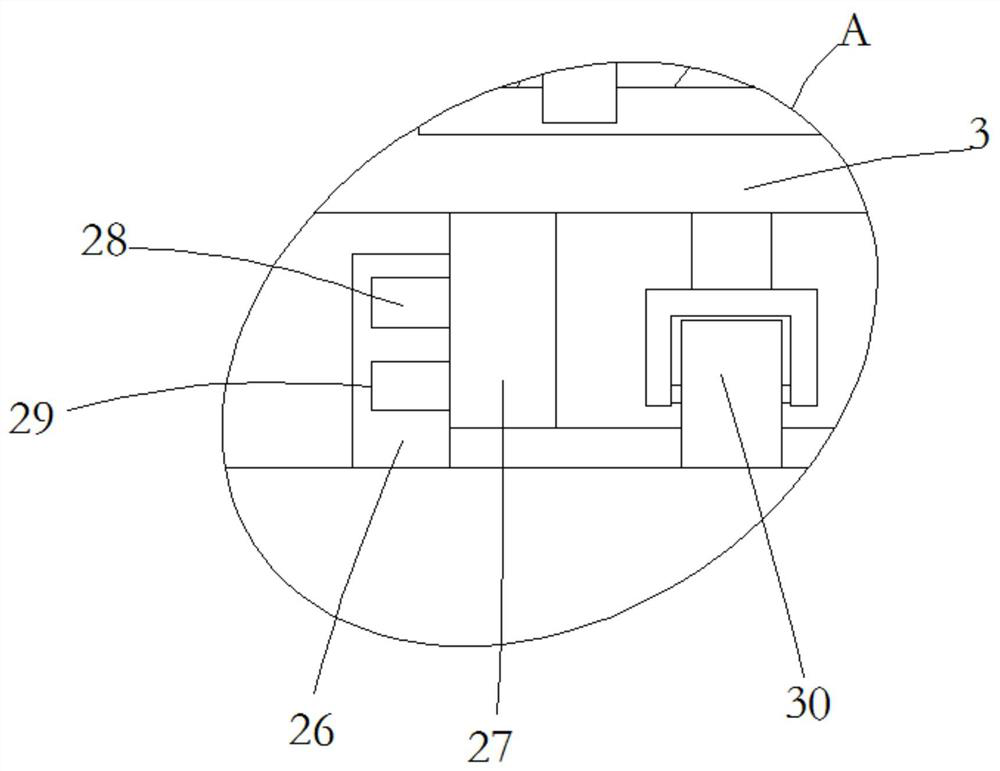

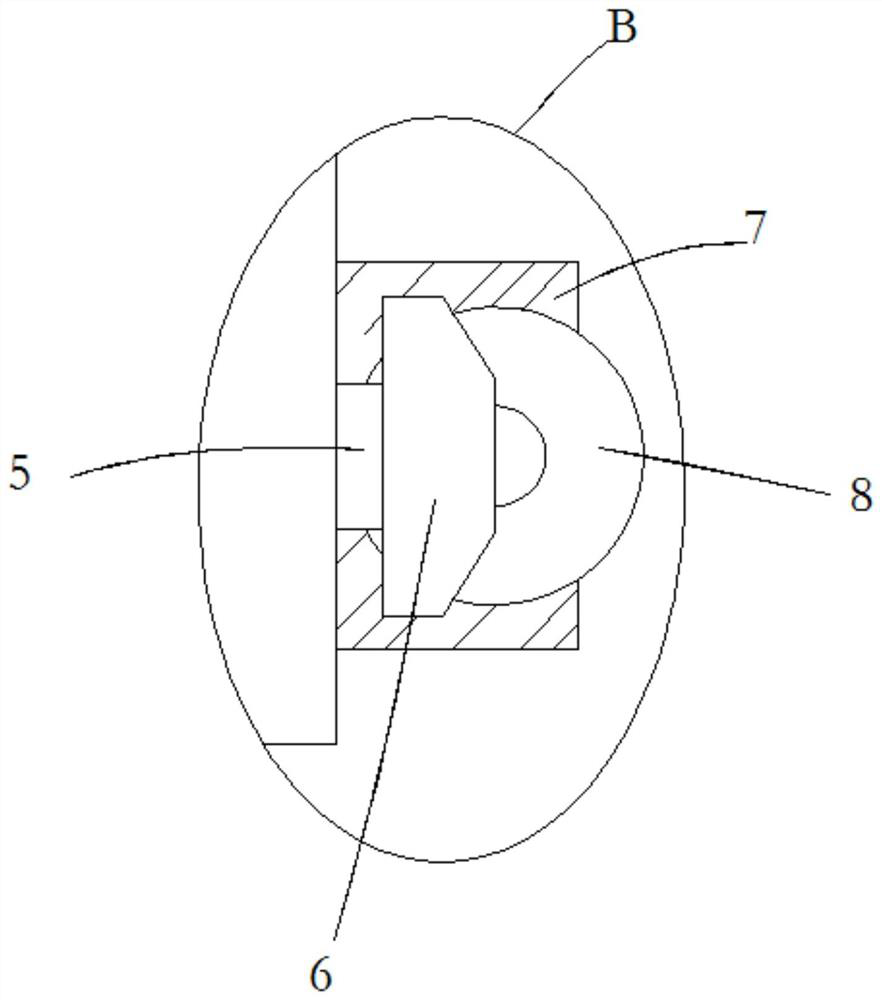

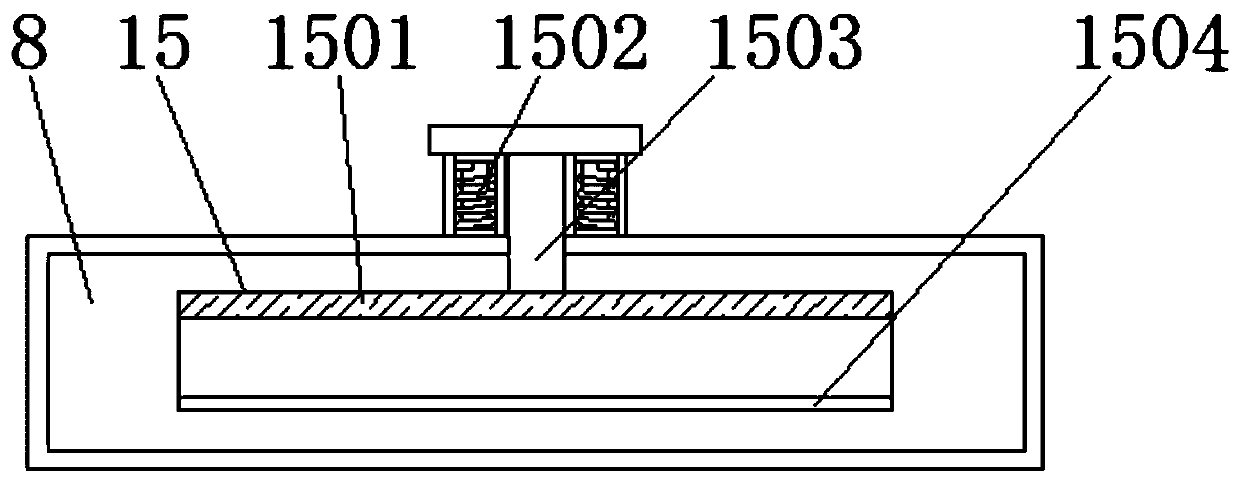

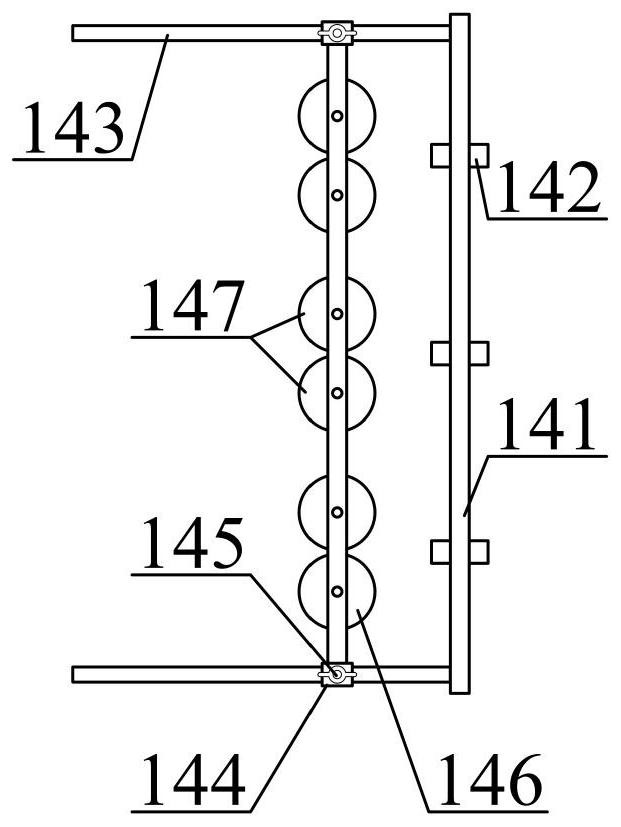

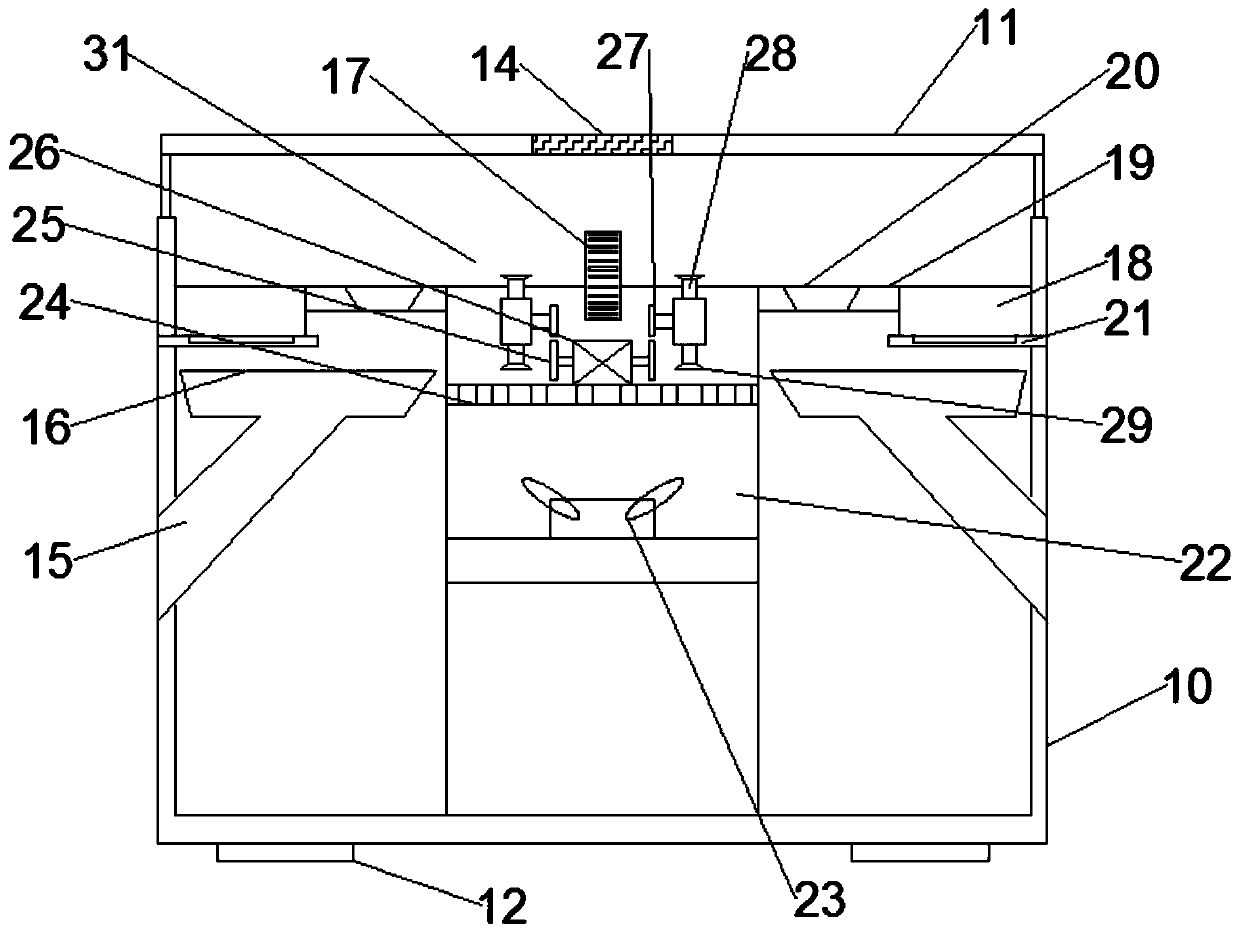

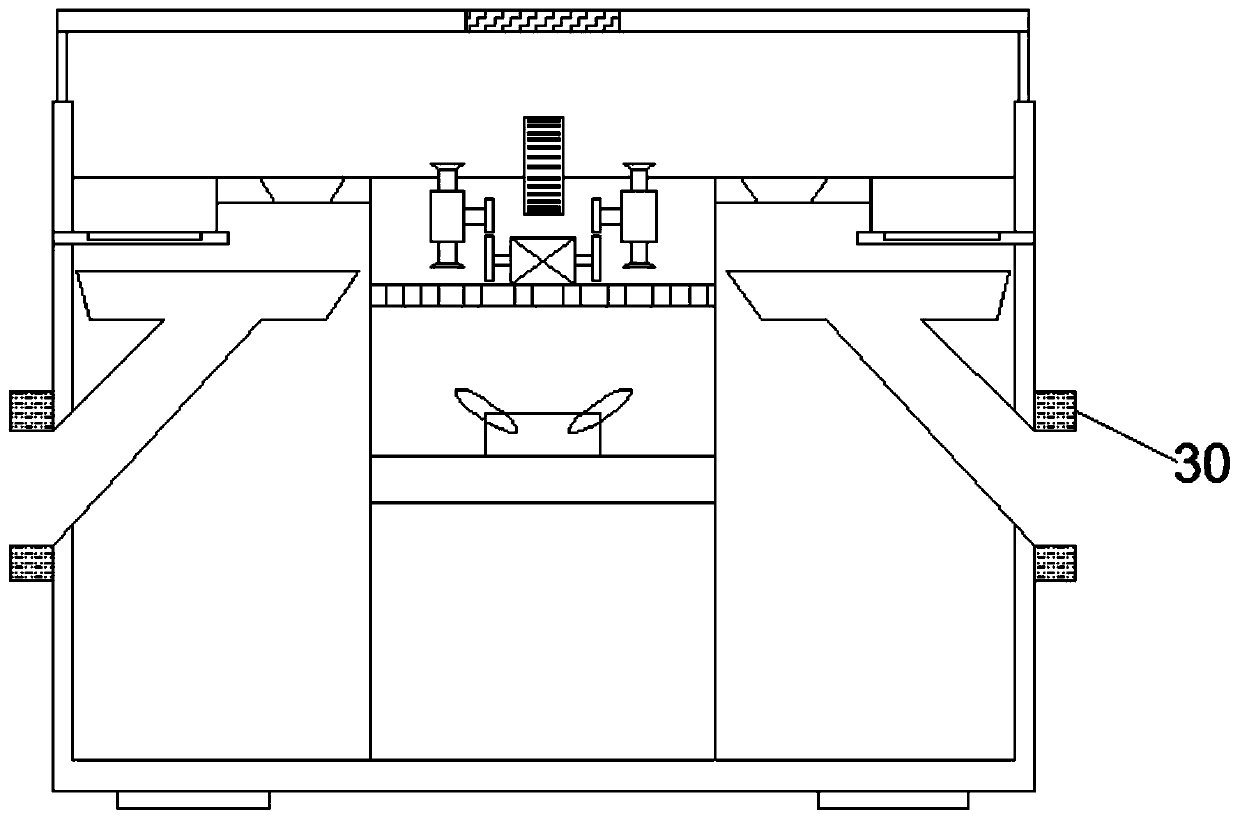

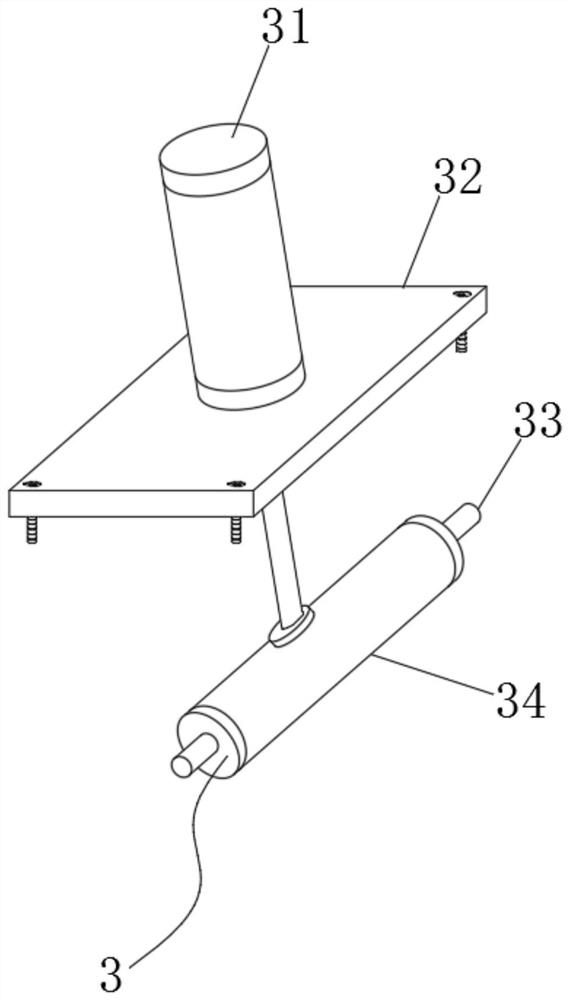

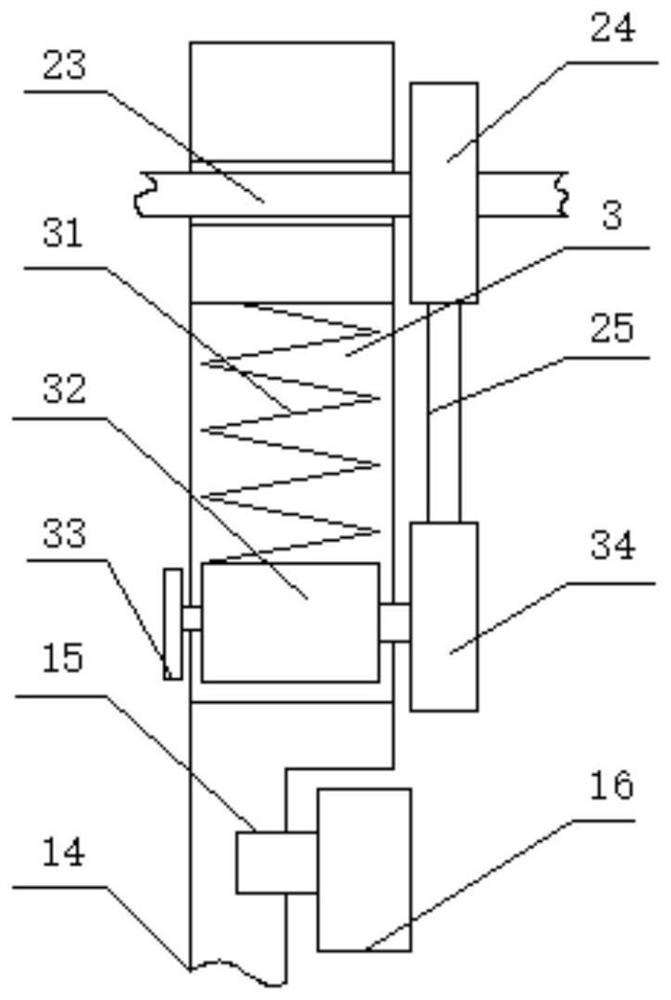

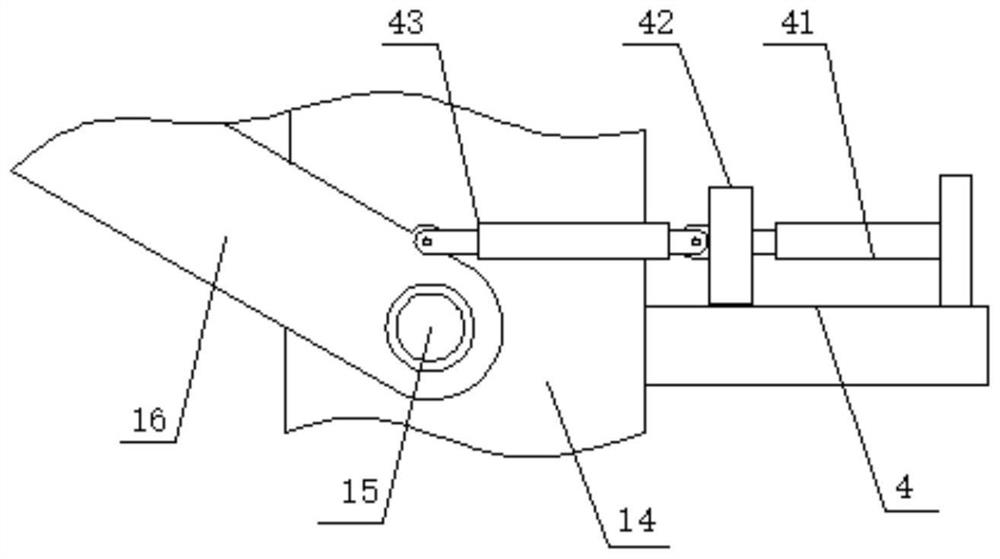

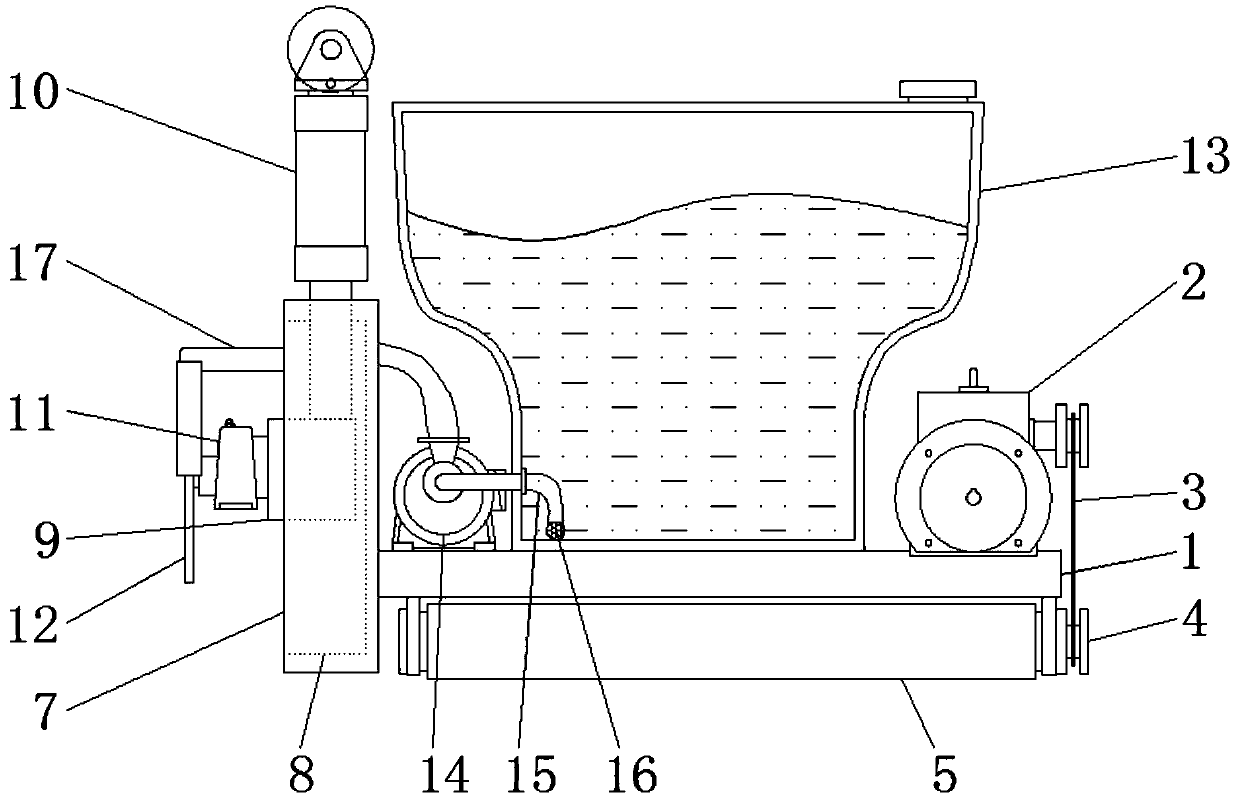

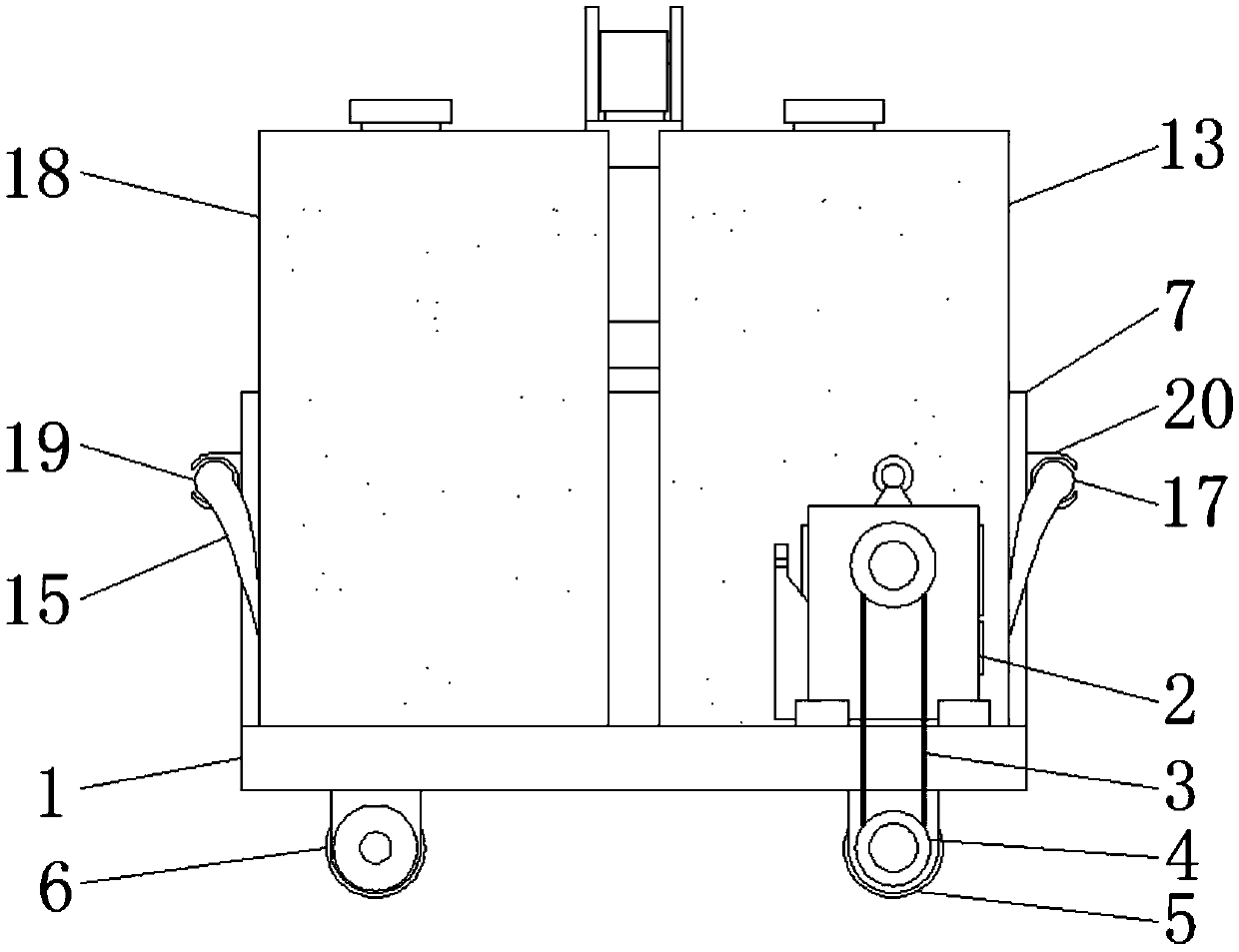

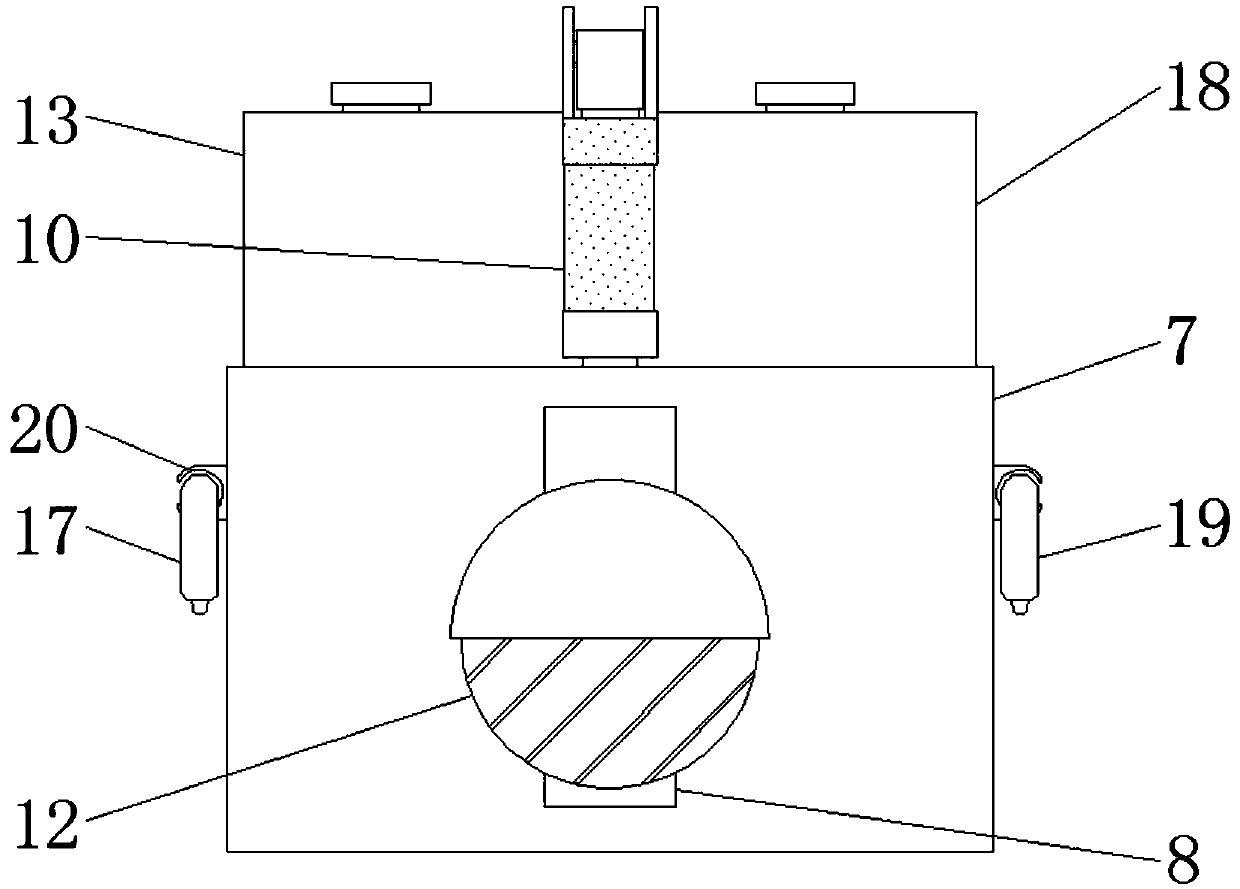

Motorcycle part rod positioning cutting auxiliary system

InactiveCN106624973AEasy to cut and useEasy positioning and cuttingMaintainance and safety accessoriesEngineeringAuxiliary system

The invention relates to a motorcycle part rod positioning cutting auxiliary system. The motorcycle part rod positioning cutting auxiliary system comprises a lower support mechanism; a rod treatment chamber is mounted at the upper part of the lower support mechanism; a left bearing frame and a right bearing frame are respectively mounted on the left and right two sides of the rod treatment chamber; an upper support mechanism is mounted at the upper part of the rod treatment chamber; a left dust removing system and a right dust removing system are respectively mounted on the left and right two sides of the upper part of the upper support mechanism, and are respectively provided with powder waste feeding pipes at the lower parts; powder waste feeding systems are arranged at the lower parts of the powder waste feeding pipes; rotating systems are mounted at the lower parts of the powder waste feeding systems; and rotating mechanisms are mounted in the middle positions of the rotating systems. The system can effectively position motorcycle part rods, and is convenient to cut and use.

Owner:CHONGQING YUANHUANG MACHINERY MFG CO LTD

Giant salamander meat processing cutting device

The invention provides a giant salamander meat processing cutting device which comprises a base, a supporting column is fixedly installed on the base, a sliding plate is slidably installed on the supporting column, a fixing plate is fixedly installed on the supporting column, a sliding mechanism is installed between the sliding plate and the supporting column, and a first spring is fixedly installed between the fixing plate and the sliding plate. A rotating column is fixedly installed on the sliding plate, a blade is rotatably installed on the rotating column, a motor is fixedly installed on the rotating column, the driving end of the motor is fixedly connected with the blade, two supports are fixedly installed on the sliding plate, and a supporting rod is installed on each support in a sliding mode. According to the device, giant salamander meat can be effectively fixed, the safety risk existing in the cutting process is reduced, and meanwhile the labor intensity needed by cutting iseffectively reduced through mechanical cutting.

Owner:竹溪县隆源大鲵生物开发有限公司

Architecture prestress concrete hollow slab wet cutting device convenient to move

PendingCN109551648AAvoid damageEasy wet cuttingWorking accessoriesStone-like material working toolsTransmission beltPre stress

The invention discloses an architecture prestress concrete hollow slab wet cutting device convenient to move. The architecture prestress concrete hollow slab wet cutting device convenient to move includes a base plate, a fixing rack and a water tank, a first driving motor is arranged on the upper part of the right end of the base plate, the output terminal of the first driving motor is connected with a transmission belt, the bottom end of the transmission belt is connected with a transmission wheel, the inner side of the transmission wheel is connected with a driving roller, a driven roller isarranged on the front side of the driving roller, the fixing rack is fixedly welded to the left end of the base plate, the top end of the fixing rack is connected with an air cylinder, a second driving motor is arranged outside a fixing block, the water tank is installed on the middle of the base plate, the left end of the water tank is connected with a material pump, the input terminal of the material pump is connected with a filter head, and fixing clampers are arranged at the front end and the back end of the fixing rack. According to the architecture prestress concrete hollow slab wet cutting device convenient to move, wet cutting is convenient to conduct, damage of concrete hollow slabs is prevented, use is convenient, and production efficiency is improved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Cut-off equipment provided with flat pressing mechanism and used for constructional engineering

ActiveCN113042657AEasy to fixFixing so that the rebar can be held in place for cuttingRebarEquipment use

The invention provides cut-off equipment provided with a flat pressing mechanism and used for constructional engineering, relates to the technical field of construction machinery, and aims to solve the problems that when existing cut-off equipment used for constructional engineering is used to cut off a plurality of reinforcing steel bars, due to the lack of auxiliary flat pressing mechanisms, the reinforcing steel bars cannot be arranged orderly to be cut off. The equipment comprises a main body, a bearing plate and a lateral piece, wherein the main body is of a rectangular structure, a baffle is arranged on the left side of the top end of the main body, and a bearing plate is arranged on the right side of the main body and is made of metal. When the equipment is used, a flat pressing piece can be installed above the bearing plate, so that the flat pressing piece can be installed and used, then a pressing plate is controlled to move downwards through heating power and pull rods to enable the pressing plate to control a contact piece to press and fix a plurality of reinforcing steel bars, and the reinforcing steel bars can be fixed and cut; and meanwhile, when a moving piece drives a cutting piece to move, embedded parts are embedded into T-shaped grooves in the top end of the flat pressing part, so that the flat pressing piece can be automatically stressed and pressed downwards, and the flat pressing effect is further enhanced.

Owner:广东竣崑建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com