Electric wire and cable rotating mold convenient to maintain

A technology of rotating molds and wires and cables, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of unstable traction speed, affecting cutting efficiency, inconvenient disassembly and maintenance of stranded wires, etc., to ensure the efficiency of parallel stranding , Guarantee the efficiency of outgoing line and the effect of ensuring the convenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

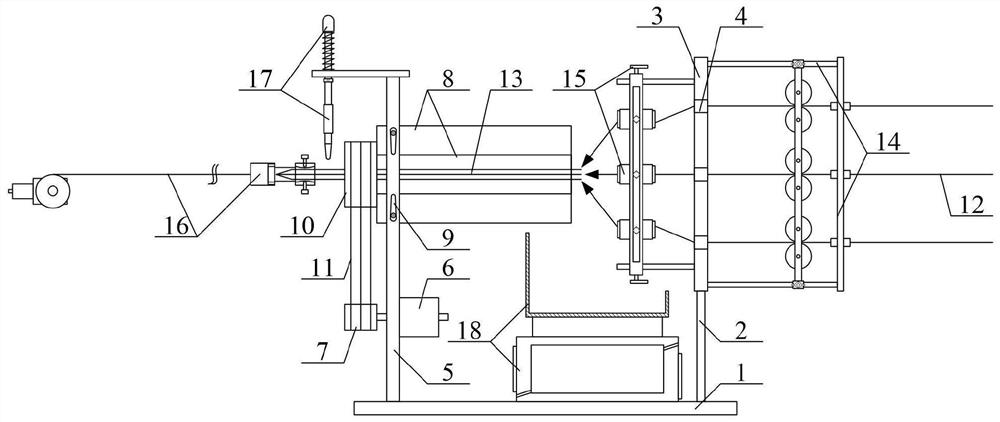

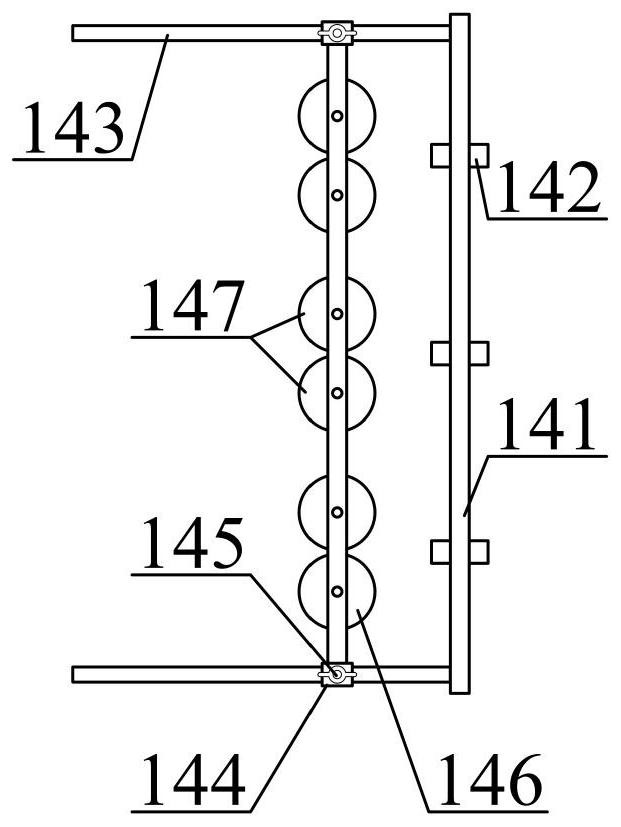

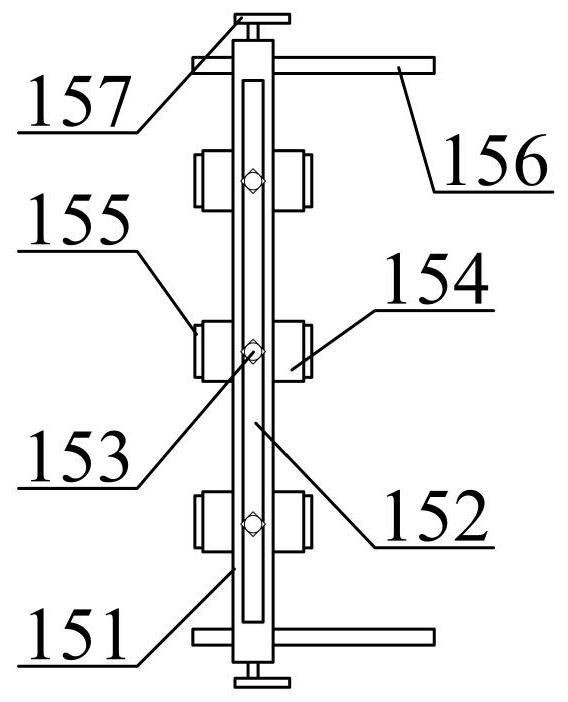

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a wire and cable rotary mold that is easy to maintain includes a frame 1, a longitudinally arranged support frame 2 is bolted to the upper right side of the frame 1, and a longitudinally arranged branch line is bolted to the upper end of the support frame 2 Disc 3, and wire entry holes 4 are provided around the interior of the distribution disc 3; a vertically arranged bracket 5 is bolted on the upper left side of the frame 1, and a horizontally arranged bracket 5 is bolted on the middle part of the lower right side of the bracket 5. Servo motor 6, and the output shaft of the servo motor 6 runs through the inside of the bracket 5, and is keyed to the driving pulley 7; in the inside of the bracket 5, the upper side bearing is connected with a parallel rotating mold body 8, and through the quick release bolt 9 Connection setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com