Inclined feeding device for cylindrical material

A cylindrical, feeding device technology, applied in the direction of destacking of objects, conveyor objects, transportation and packaging, etc., can solve the problems of increasing product transportation costs and large installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

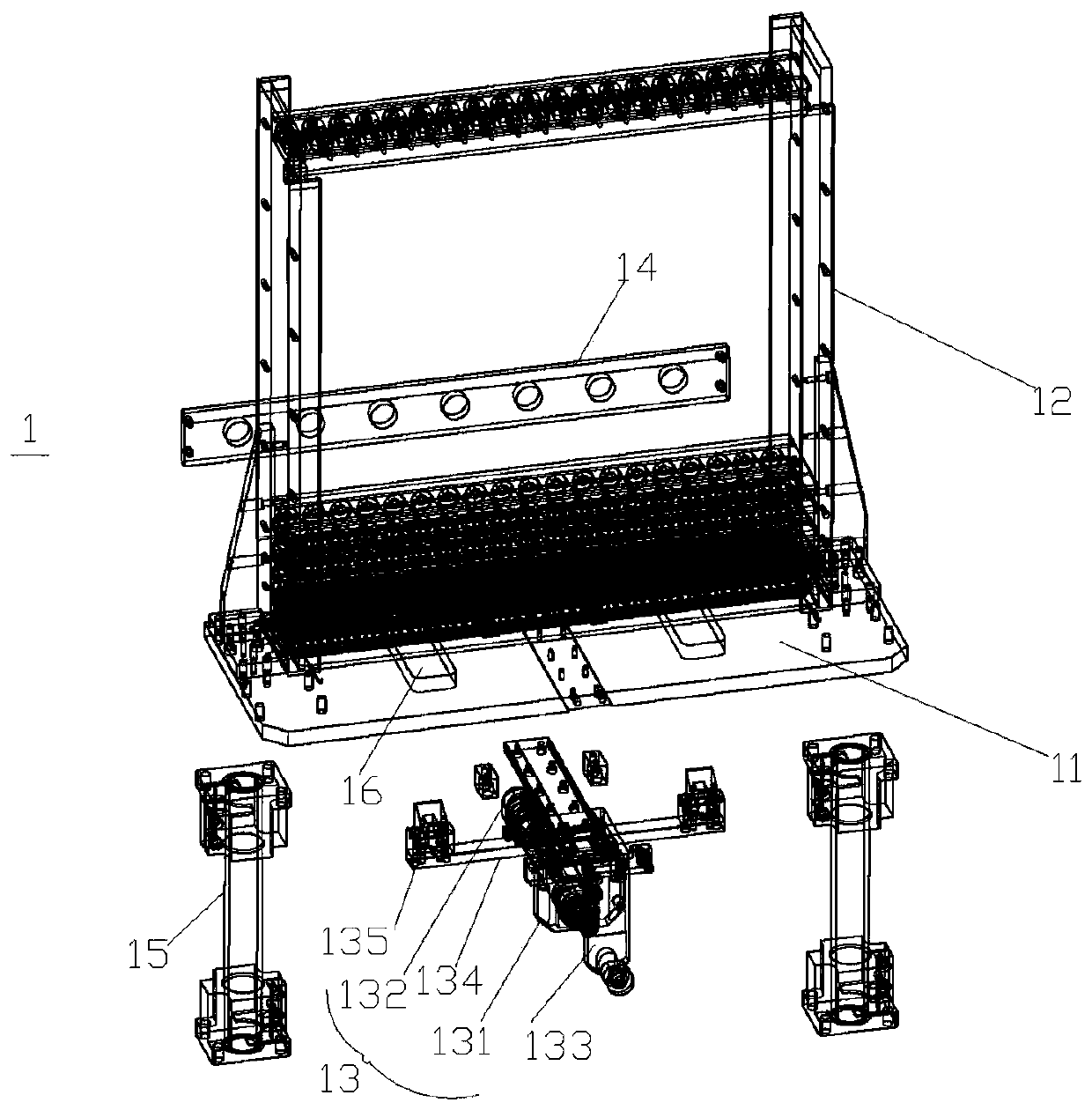

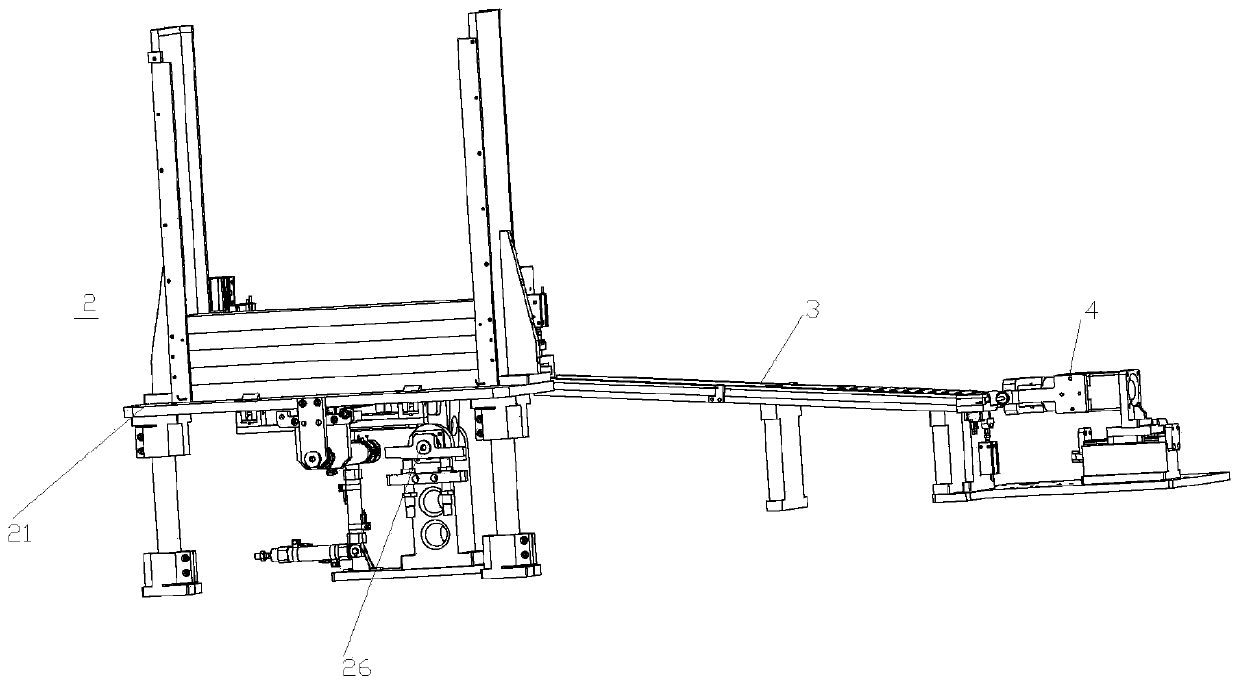

[0030] Such as Figure 1 to Figure 5 As shown, a cylindrical material inclined feeding device includes a material box stacking feeding device 1, a material box inclined self-gravity feeding device 2, and an inclined conveying track 3 docked with the outlet of the material box inclined self-gravity feeding device 2 And the material rotation mechanism 4 arranged at the discharge end of the inclined conveying track 3, the material rotation mechanism 4 rotates a single product by 90 degrees and stands upright, and then is picked up and transported by the feeding manipulator 5.

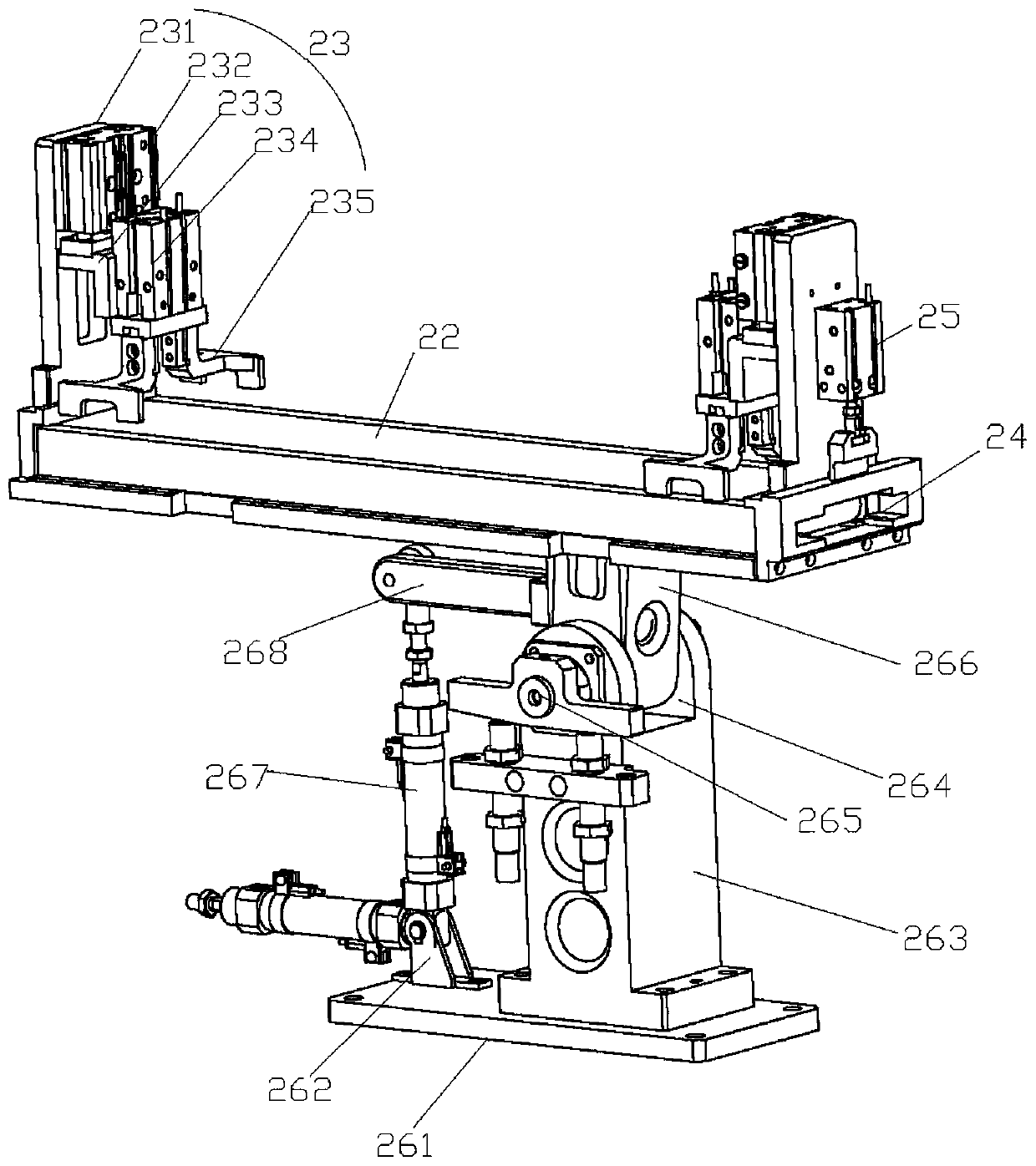

[0031] Preferably, the material box tilting self-gravity feeding device 2 comprises a material box positioning bracket 21, the material box positioning bracket 21 is provided with a material box positioning groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com