a washer

A technology of gaskets and pads, which is applied in the direction of gaskets, connecting components, mechanical equipment, etc., can solve the problems of affecting the safe operation of connecting parts, spring gasket expansion, flat gasket extrusion depression, etc., to reduce excessive clamping force , increase the friction contact force, reduce the effect of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

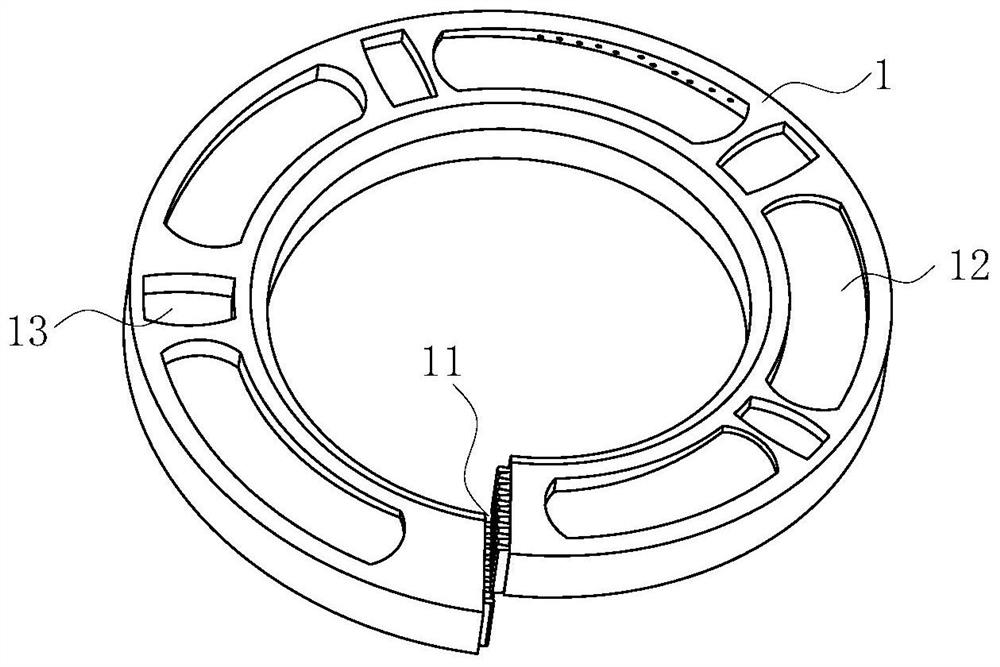

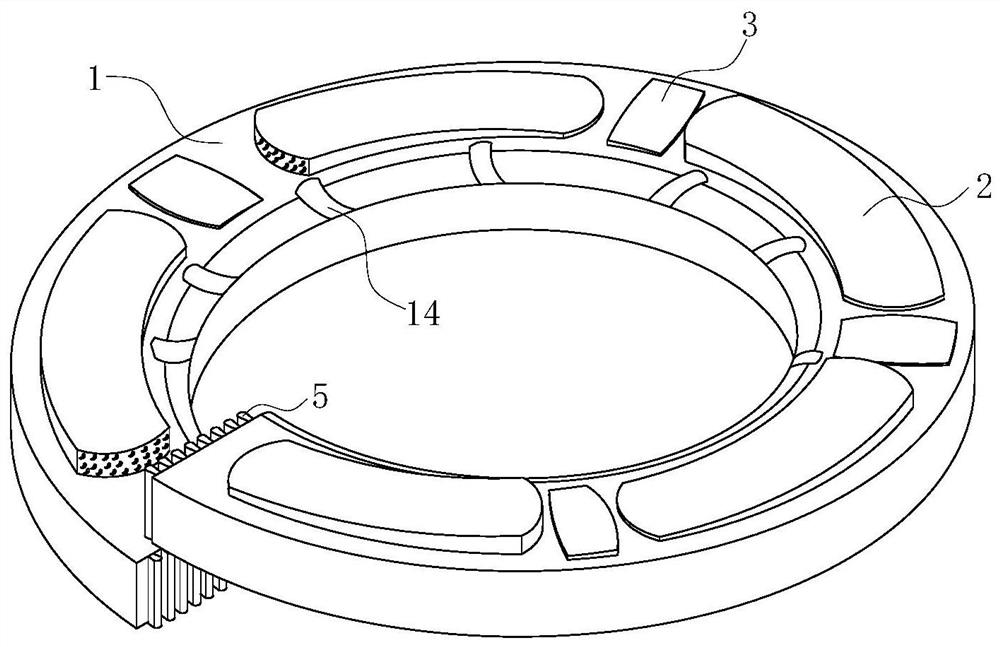

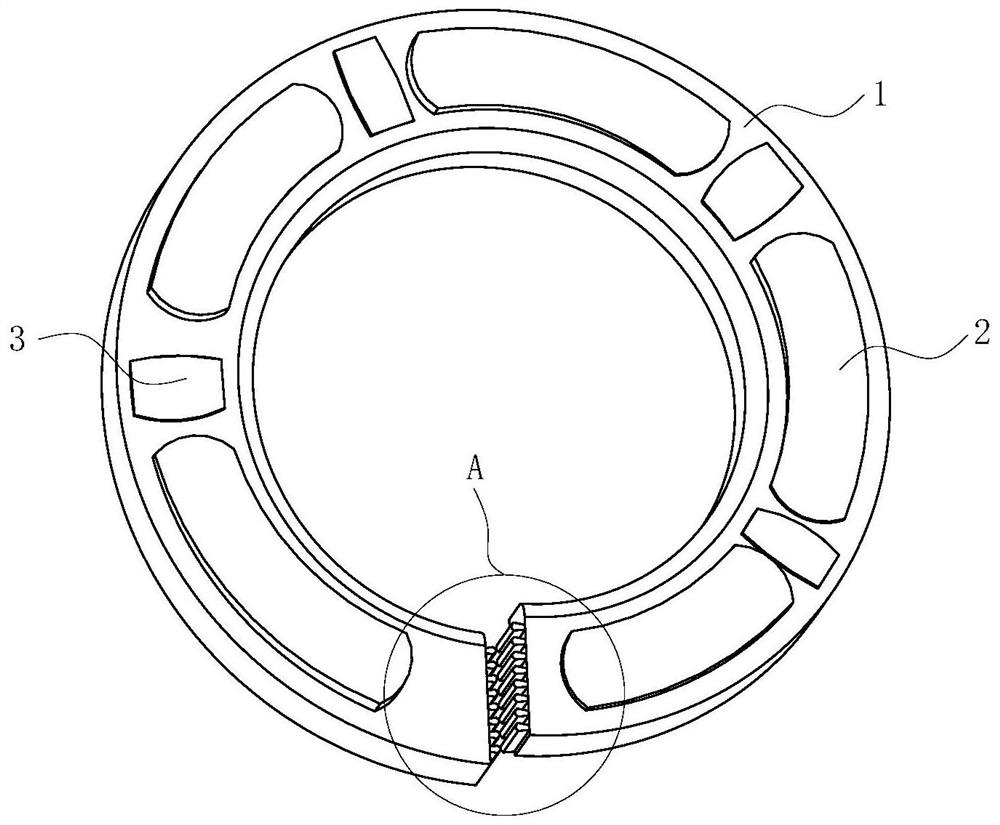

[0021] use Figure 1-Figure 4 A gasket according to one embodiment of the present invention will be described below.

[0022] Such as Figure 1-Figure 4 As shown, a gasket according to the present invention includes a gasket body 1; the gasket body 1 is made of spring steel material, and the gasket body 1 is provided with a cutout 11; the gasket body 1 is provided with a plurality of arc-shaped Recessed groove 12, and the groove depth of one end of a plurality of arc-shaped recessed grooves 12 is greater than the groove depth of the other end; Arc-shaped thin spacer 2 is all installed in a plurality of described arc-shaped recessed grooves, and arc-shaped thin spacer 2 It is set to hard alloy material, and the arc-shaped thin spacer 2 is an interference fit with the arc-shaped concave groove; a limiting groove 13 is set between adjacent arc-shaped concave grooves 12, and a limiting metal block is installed in the limiting groove 13 3, and the limit metal block 3 is set as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com