RFID-based Shelf tool inventory method, system and device and medium

A technology of tools and shelves, applied in the field of electric power tool management, can solve the problem of inefficient inventory of tools and other problems, and achieve the effect of avoiding manual inventory and missing reading, reducing inventory errors, and improving inventory efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

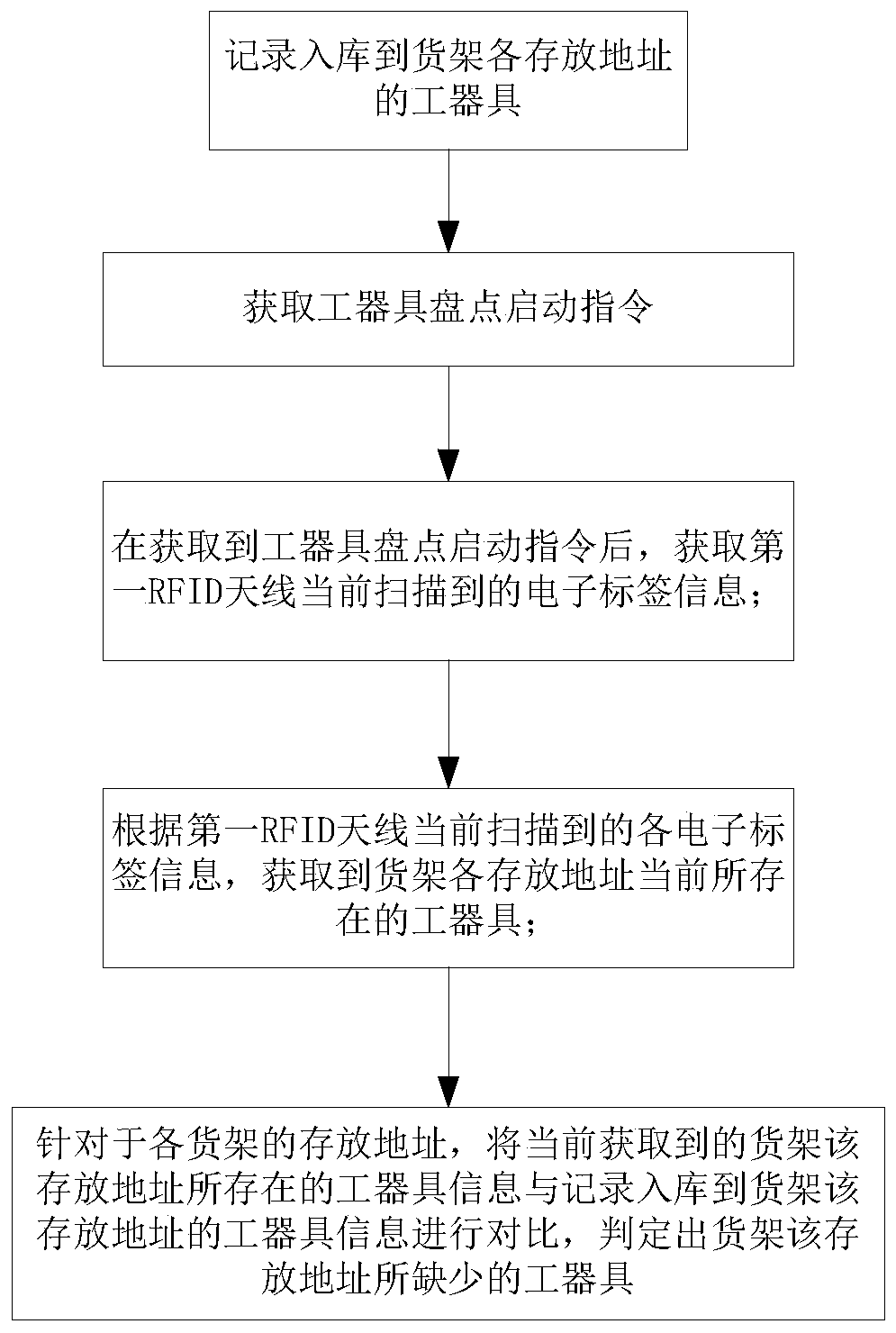

[0076] This embodiment discloses a method for inventorying shelf tools and utensils based on RFID, which can be implemented on computing devices such as computers and servers, such as figure 1 shown, including the following steps:

[0077] S1. Recording the tools and appliances from the warehouse to the storage addresses of the shelves; among them, for some large power plants and other places, there are usually multiple tool and appliance warehouses, and each warehouse includes multiple shelves, and the shelf structure is set so that the shelf It includes multiple cells, and each cell stores one or more tools; the storage address of the shelf in this embodiment is mainly composed of the warehouse number where the shelf is located, the shelf number, and the cell number on the shelf, such as the storage address of the shelf If it is 1-1-1, it corresponds to cell 1 of shelf 1 in warehouse 1.

[0078] S2. Obtain the tool inventory start instruction; in this embodiment, the tool i...

Embodiment 2

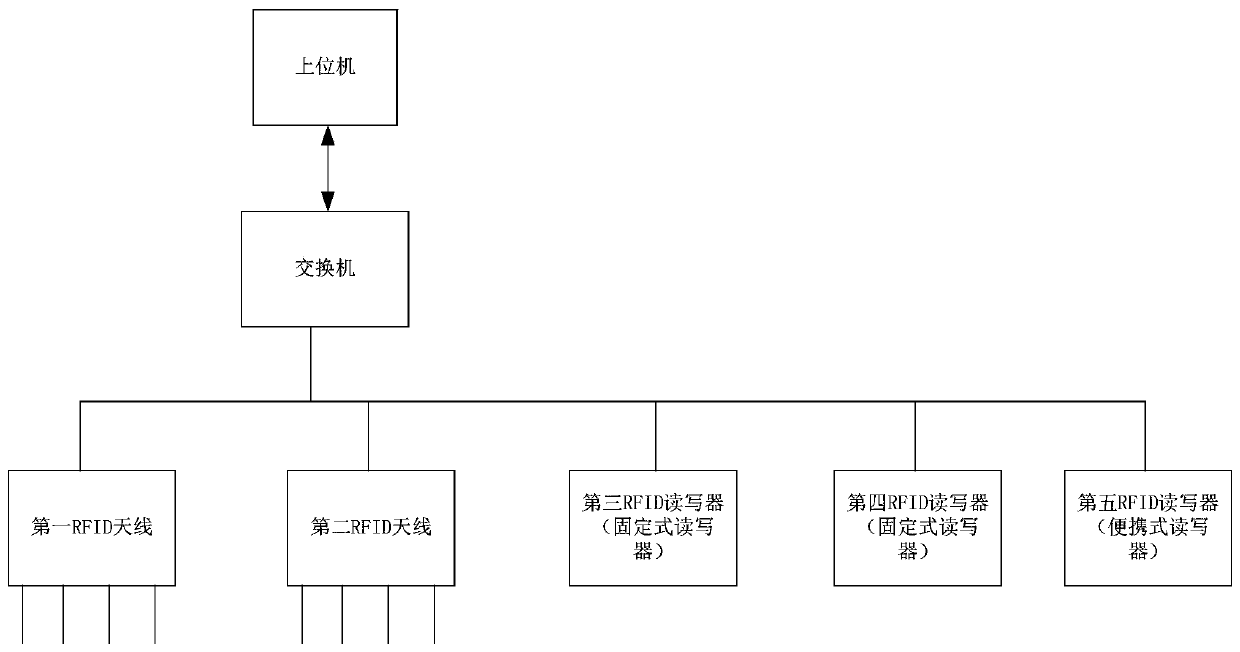

[0107] This embodiment discloses an RFID-based shelf tool inventory system, through which the shelf tool inventory method shown in Embodiment 1 can be realized, such as image 3 As shown, it includes a host computer, a first RFID antenna, a second RFID antenna, a third RFID reader, a fourth RFID reader and a fifth RFID reader; the first RFID antenna, the second RFID antenna, the third The RFID reader-writer, the fourth RFID reader-writer and the fifth RFID reader-writer are respectively connected to the host computer through the switch.

[0108] in:

[0109] The first RFID antenna is arranged on the shelf or beside the shelf, and is used to scan the electronic tags on the tools on the shelf, and transmit the scanned electronic tag information to the host computer. The number of the first RFID antennas is configured according to the size and mechanism of the shelf, and the layout of the first RFID antenna makes all storage addresses on the shelf fall within the coverage of the...

Embodiment 3

[0144] This embodiment discloses a storage medium, which stores a program. When the program is executed by a processor, the RFID-based shelf tool inventory method described in Embodiment 1 is implemented, as follows:

[0145] (1) Record the tools and appliances that are put into the warehouse and stored at each storage address on the shelf;

[0146] (2) Obtain the starting instruction of tool inventory;

[0147] (3) After obtaining the tool inventory start instruction, obtain the electronic tag information currently scanned by the first RFID antenna;

[0148] (4) According to the information of each electronic tag currently scanned by the first RFID antenna, obtain the tools and utensils currently present in each storage address of the shelf; wherein, each storage address of the shelf is located within the coverage of the first RFID antenna;

[0149] The specific process of obtaining the tools and appliances in each storage address of the shelf is as follows:

[0150] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com