Shell component of permanent magnet motor and permanent magnet motor

A technology of permanent magnet motors and components, which is applied in the direction of electric components, electrical components, casings/covers/supports, etc., which can solve the problems of affecting the operating efficiency and stability of the motor, easy deformation, and high damage rate of the motor. The effect of operating efficiency and running stability, strong impact resistance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

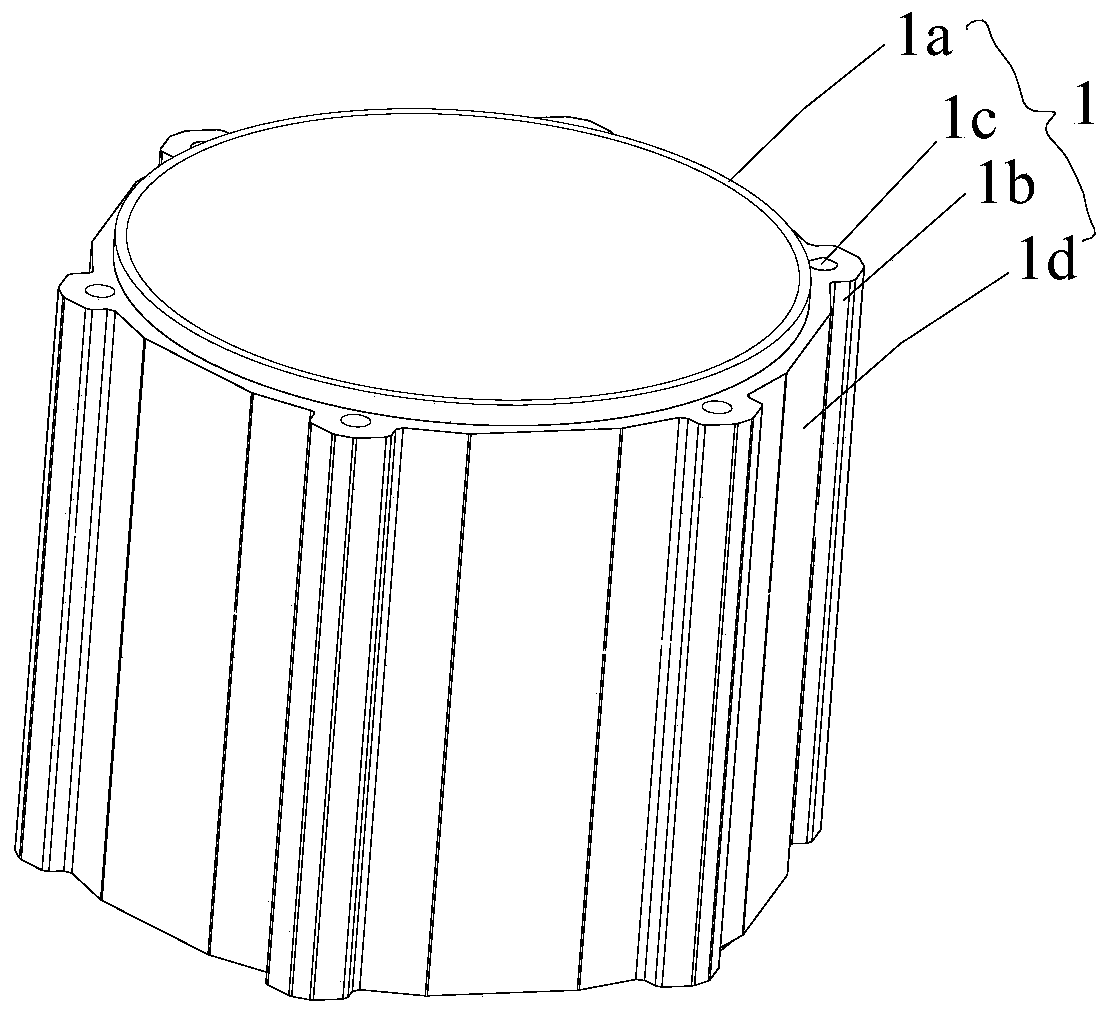

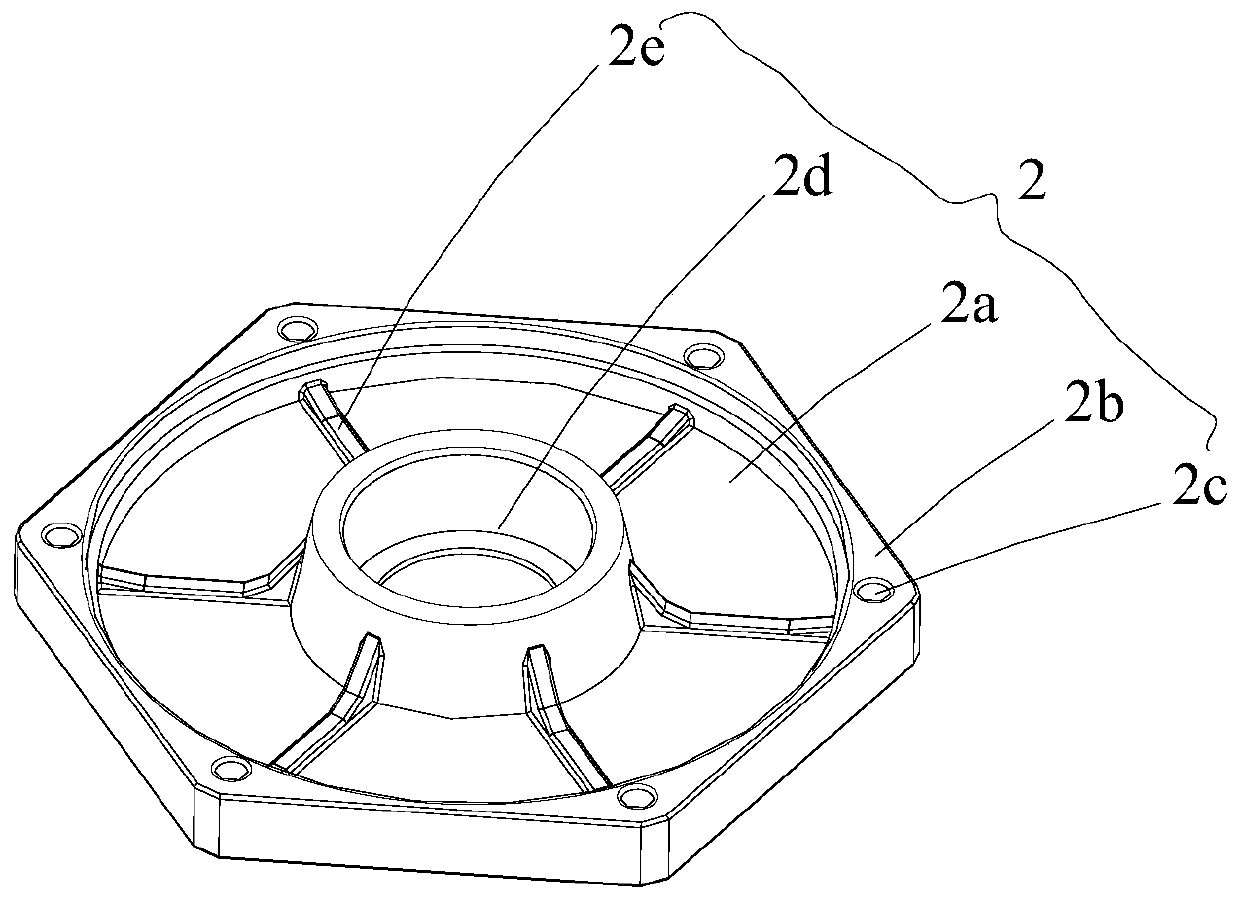

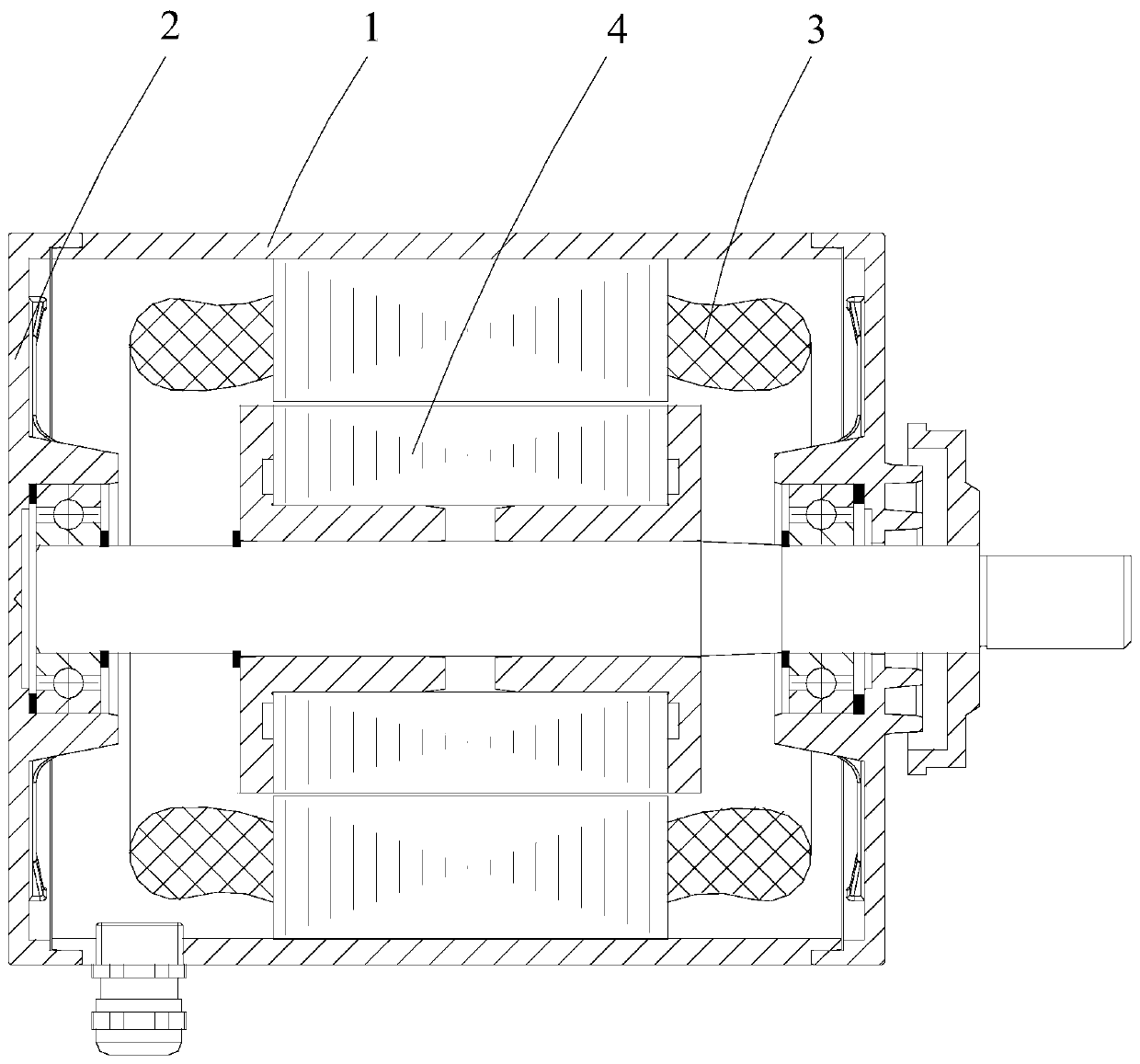

[0024] see Figure 1-3 As shown, a shell assembly of a permanent magnet motor includes a casing 1 and an end cover 2 arranged at the end of the casing 1. The casing 1 includes a casing body 1a with a circular radial cross-section surrounding the casing body. The circumferential ring of 1a is provided on a plurality of first installation parts 1b on the casing body 1a, a first installation hole 1c opened on the first installation part 1b, and a reinforcement part 1d provided between every two first installation parts 1b The end cap 2 includes an end cap body 2a with a circular radial cross section, a second mounting portion 2b with a regular polygonal cross section surrounding the end cap body 2a, and an end portion set at the second mounting portion 2b. And the second installation hole 2c is provided in one-to-one correspondence with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com