Automatic identification device for the front and back of the glass

A technology for automatic identification and glass, which is applied in measuring devices, household cleaning devices, tableware washing machines/rinsing machines, etc., and can solve the problems of glass identification and flipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

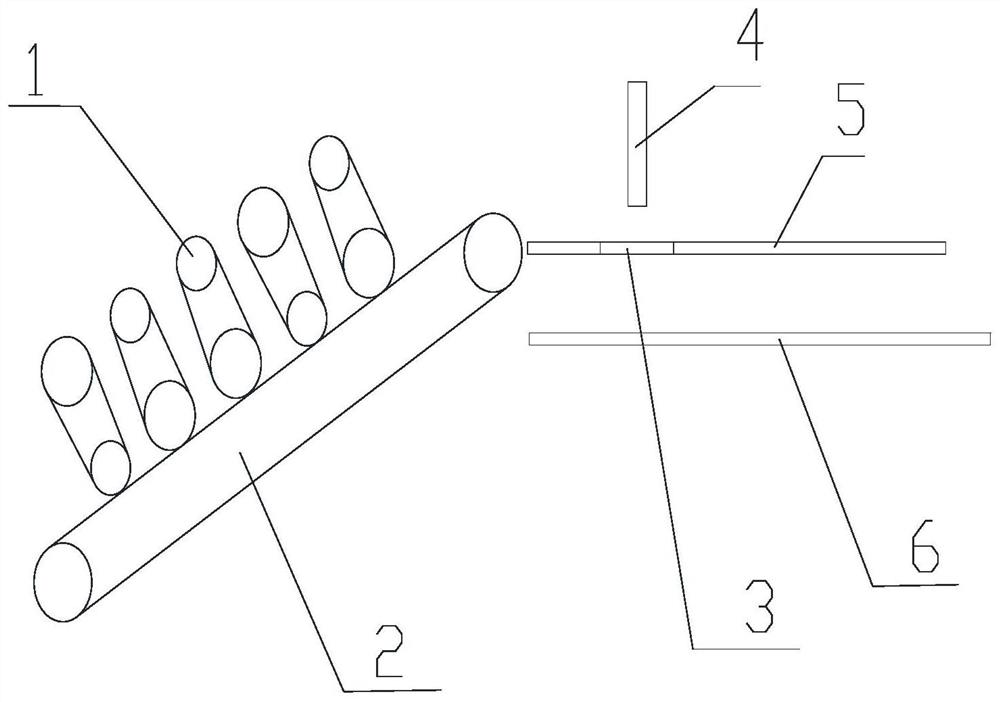

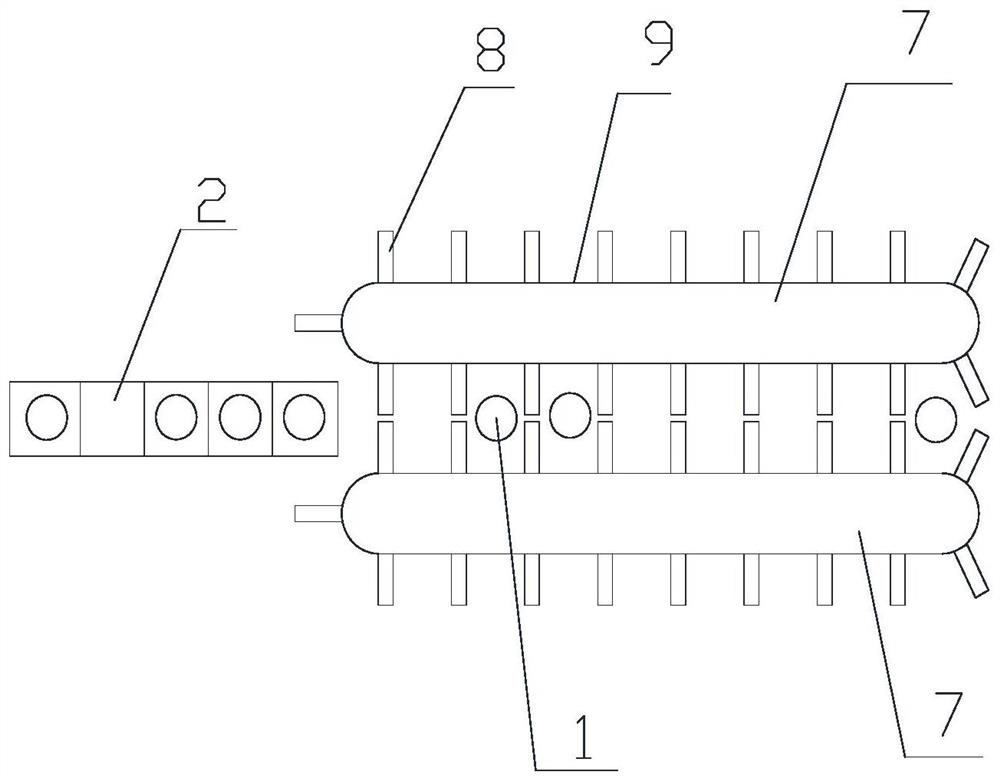

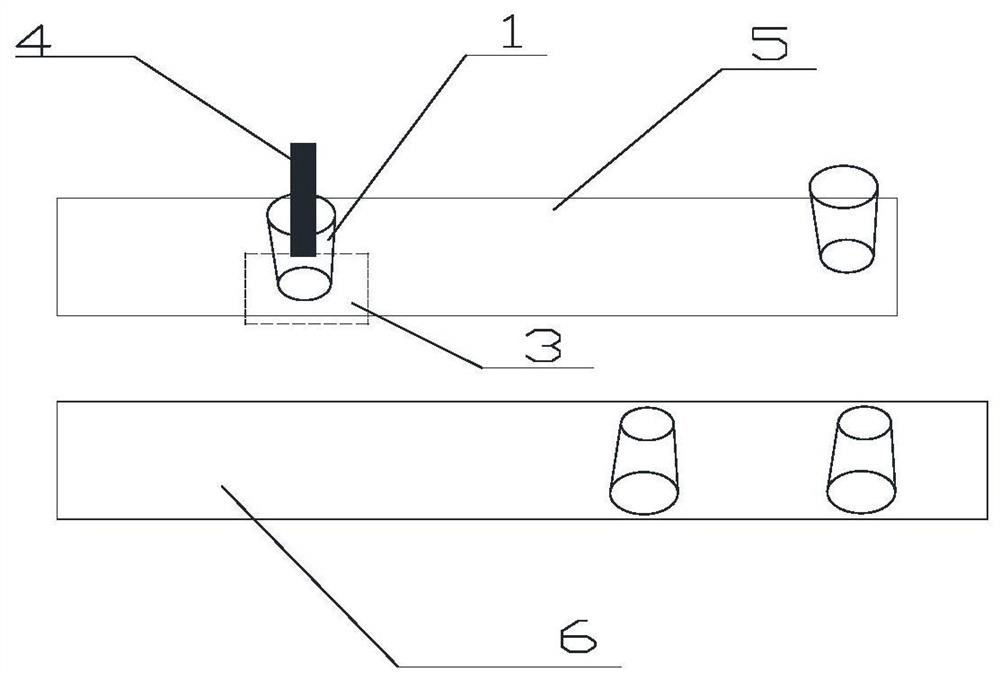

[0020] The automatic identification device for the front and back of the glass includes a pushing mechanism, a conveying mechanism, a detecting mechanism, a driving mechanism, a gate mechanism, a control mechanism and a transmission mechanism. The push mechanism is used to accept the bottle caps delivered from the upstream and push the bottle caps downstream. The gate mechanism is used to drop the identified inverted glass to the conveying mechanism below. The conveying mechanism is used to accept the reversed glass cups screened out from the gate mechanism and continue to convey downstream. The detection mechanism is used to detect the forward and reverse state of the glass traveling on the push mechanism. The driving mechanism is used to provide power for the detection mechanism and the pushing mechanism. The transmission mechanism is used to transmit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com