Vibrostand and vibrating method

A vibrating table and vibrator technology, which is applied in the field of vibrating tables and vibrating, can solve problems such as uneven vibrating and high noise of the vibrating table, and achieve the effects of improving the quality of vibrating, low working noise, and improving environmental noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

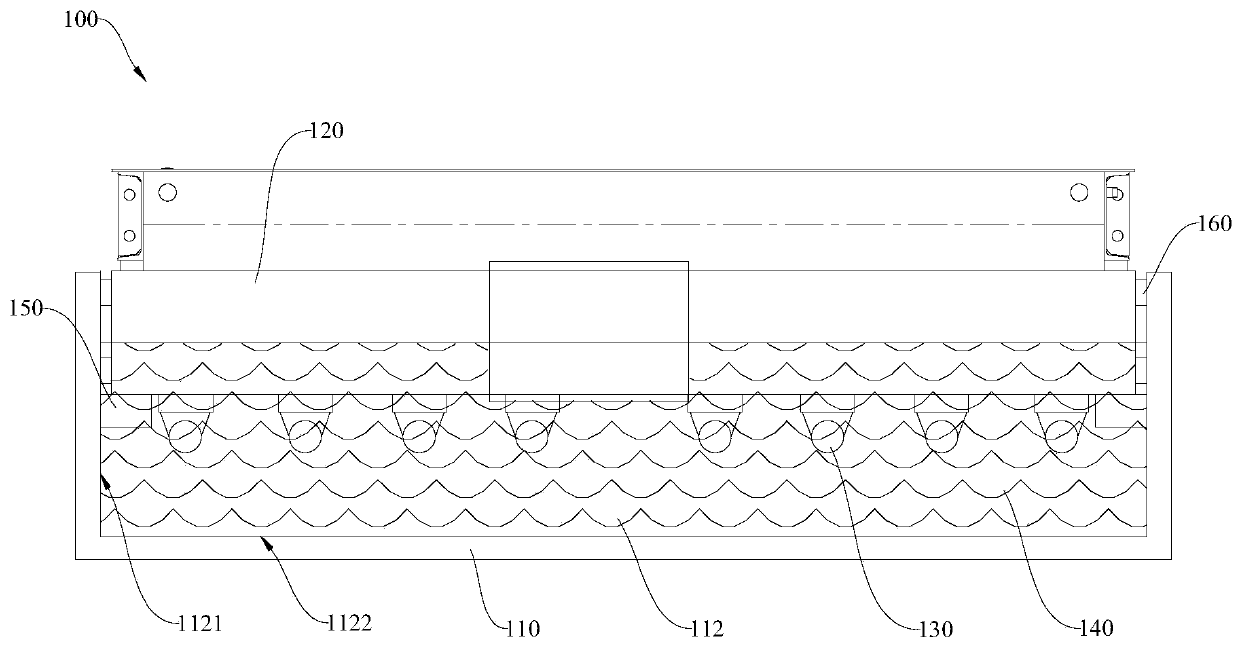

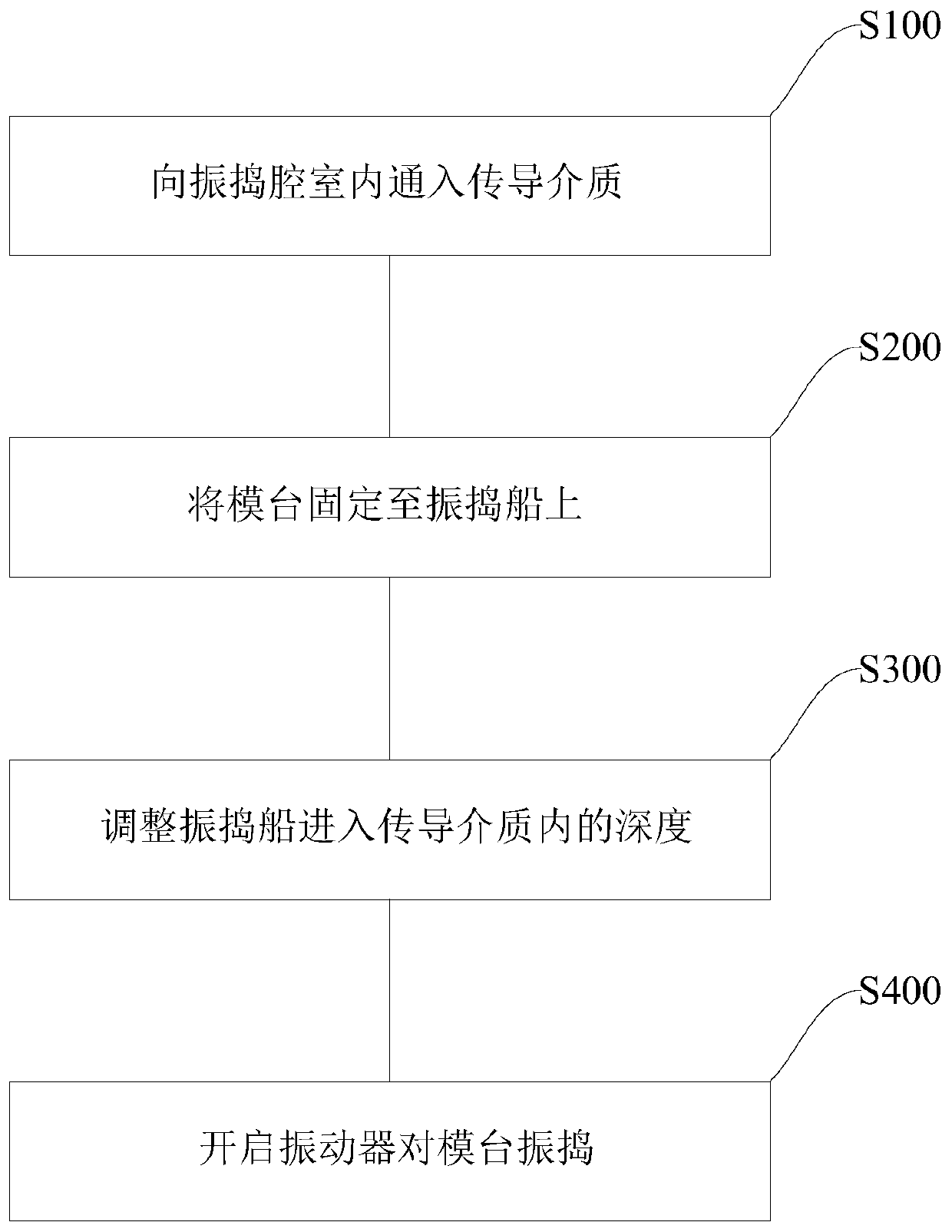

[0054] Please refer to figure 1 with figure 2 An embodiment of the present invention also provides a vibrating method for vibrating a mold table. The vibrating method uses the vibrating table 100 in the foregoing embodiment. The vibrating method includes the following steps:

[0055] Step S100: Pass the conductive medium 140 into the vibrating chamber 112.

[0056] It should be noted that the conductive medium 140 may be water, and the way of feeding may be pumping. A water pipe cooperating with the pump can be arranged around the vibrating chamber 112.

[0057] Step S200: Fix the mold table to the vibrating boat 120.

[0058] It should be noted that the method of fixing the mold table on the vibrating boat 120 can be a hook, an ejector rod or a solenoid valve. The above-mentioned hooks, ejector rods and solenoid valves can all be realized by automatic control, thereby reducing manual labor Dependence and cost, and reduce the amount of human labor.

[0059] Step S300: Adjust the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com