Rock breaking device and rock breaking machine

A rock-breaking device and articulation technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of small effective operating range and high energy consumption, and achieve the goals of improving rock-breaking efficiency, saving energy consumption, and increasing self-weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

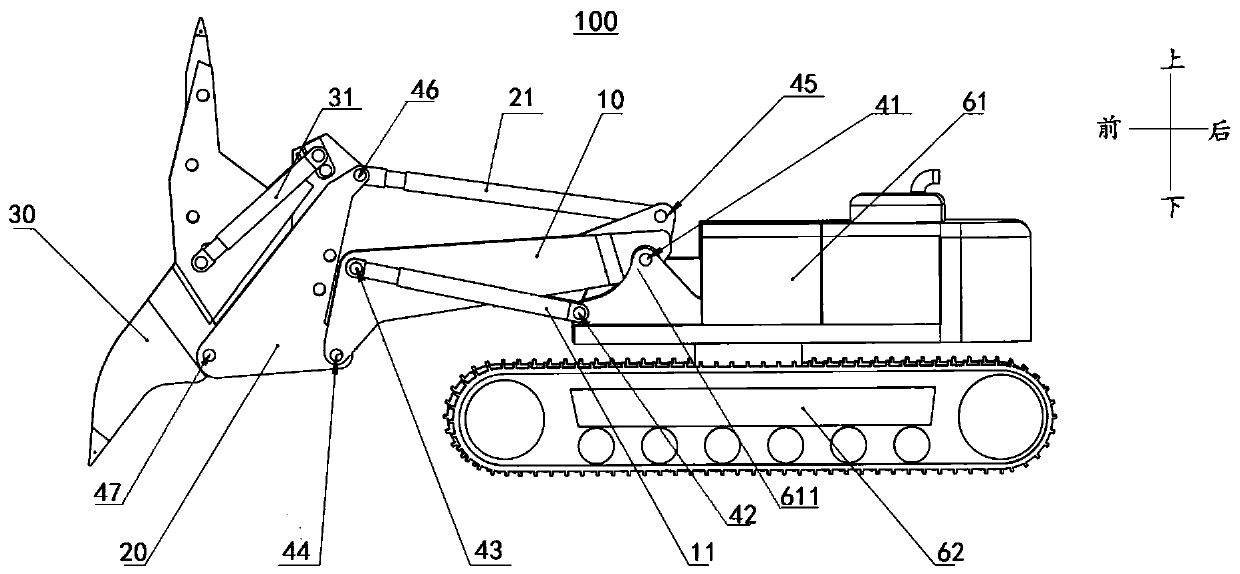

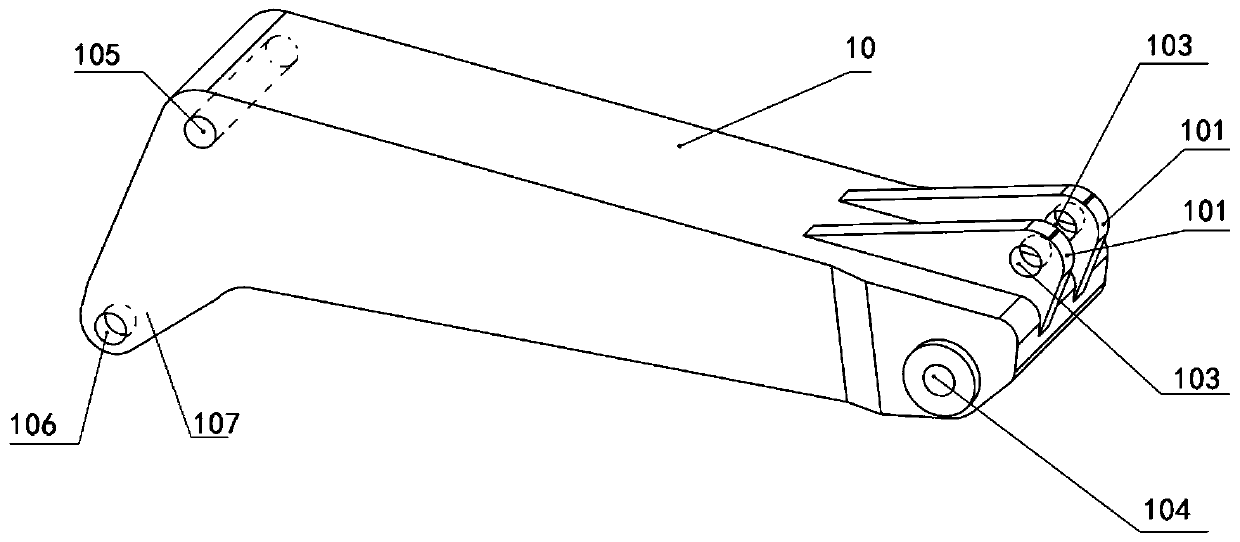

[0054] Please refer to figure 1 , this embodiment provides a rock-breaking device 100, which is applied to a carrier, and the carrier is a body part of an excavator, which is used to provide driving force for the rock-breaking device 100. The car body part of excavator has upper car body 61 and lower car body 62, and upper car body 61 is rotatably connected with lower car body 62, and lower car body 62 is provided with walking; Usually excavator is for digging, the configuration of loading material, and its The working device is usually a bucket. Due to the high penetration rate and good flexibility of the excavator, as the construction needs become more and more diverse, the working device of the excavator can be replaced to meet different construction needs. Such as breakers, rippers, grabs, etc., excavators include power parts and hydraulic parts.

[0055] In other embodiments, the vehicle may also be a loader, a bulldozer, or the like.

[0056] The upper body 61 is at le...

no. 2 example

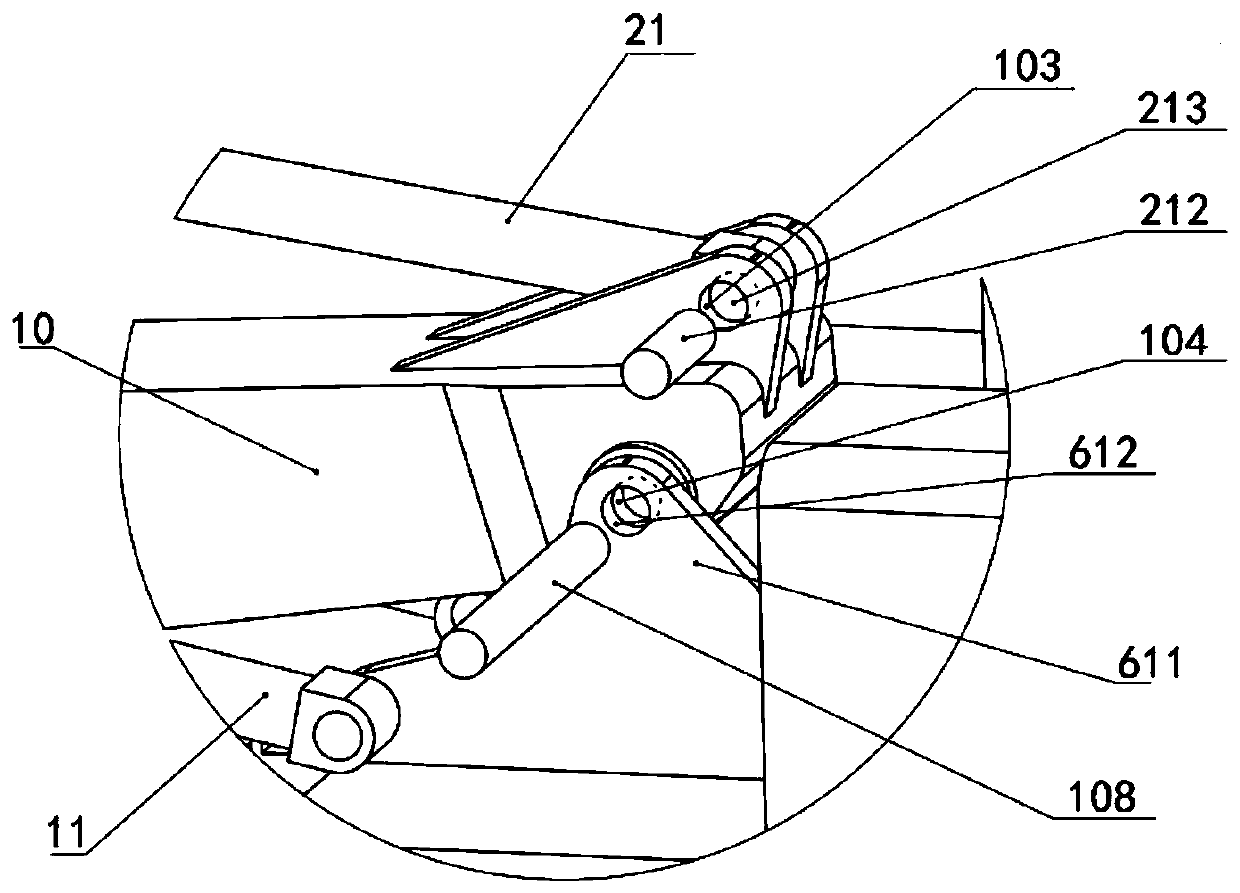

[0101] see Figure 12 as well as Figure 14 The rock-breaking device disclosed in this embodiment is different from the first embodiment in that the connection line between the first hinge position 41 and the third hinge position 43 and the connection line between the four hinge positions 44 and the third hinge position 43 constitute The second included angle is less than or equal to 120 degrees. Specifically, the plane formed by the axis of the pin shaft 108 of the first hinge position 41 and the pin axis of the third hinge position 43 is formed by the plane formed by the pin axis of the fourth hinge position 44 and the pin axis of the third hinge position 43. The second included angle formed by the formed surfaces is less than or equal to 120 degrees.

[0102] The second angle β formed by the first hinged position 41, the third hinged position 43 and the four hinged positions is less than 120 degrees, for example, 90°-120°, specifically 90°, 100°, 105°, 110°, 120° ° etc. ...

no. 3 example

[0108] see Figure 15, in this embodiment, the disclosed rock-breaking device is different from the first embodiment in that the distance from the third hinge position 43 to the line connecting the first hinge position 41 and the fourth hinge position 44 is greater than the distance from the fifth hinge position 45 to The distance between the first hinge position 41 and the fourth hinge position 44 . Specifically, the axis of the first hinge position 41 and the axis of the fourth hinge position 44 constitute the boom hinge plane 121, and the third distance L1 from the third hinge position 43 to the boom hinge plane 121 is greater than that from the fifth hinge position 45 to the boom hinge plane. The fourth distance L2 of the articulation plane 121 . When the rock-breaking device meets the structural requirements in this embodiment, it is beneficial to make the boom cylinder 11 face upwards while making the fifth hinged position 45 closer to the first hinged position 41, incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com