Gate for reducing difficulty of processing and gate valve thereof

A technology that is difficult to process and gates, applied in the field of hydraulic engineering equipment, can solve problems such as scratches and easy erosion of the sealing surface of gate valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

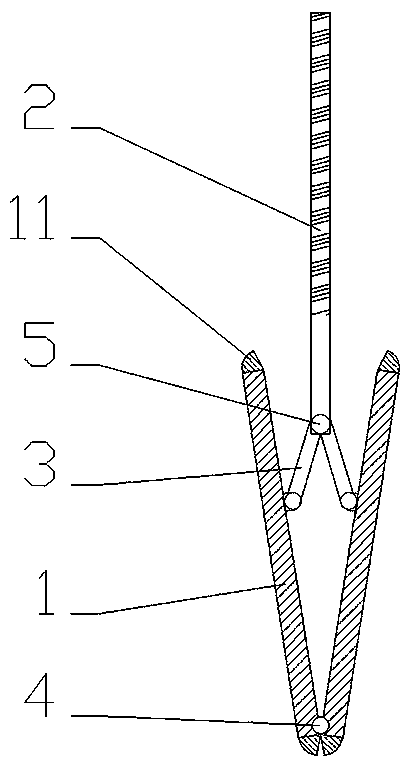

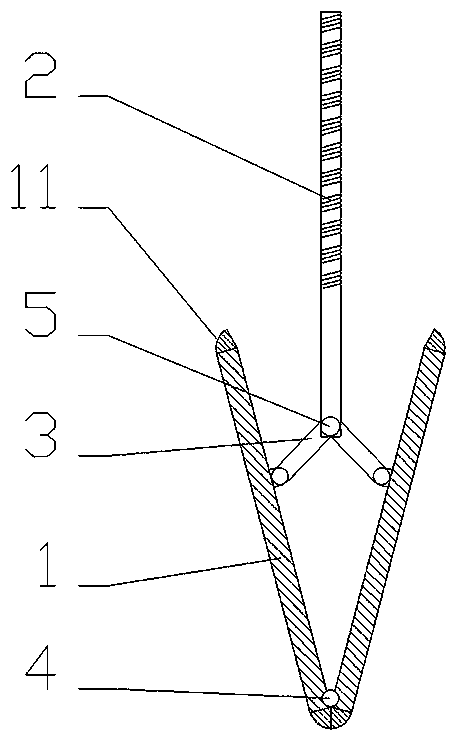

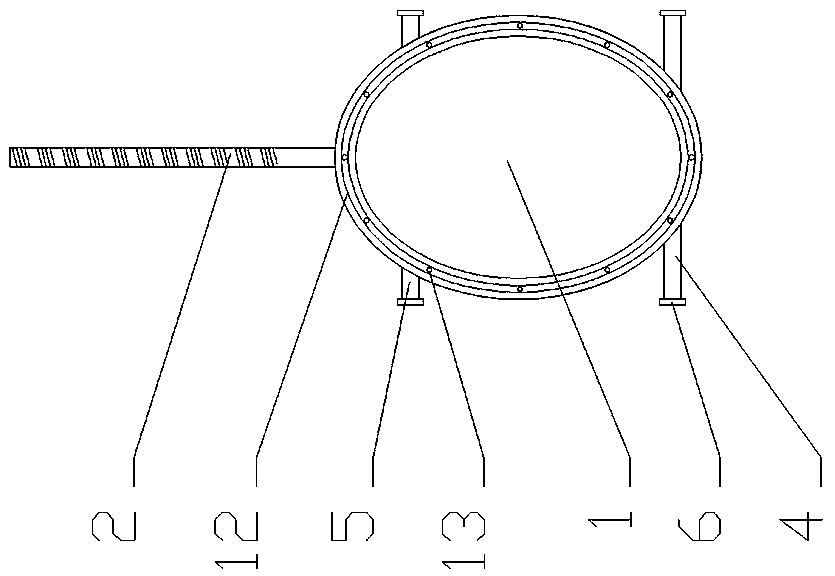

[0032] Such as Figure 1 to Figure 10 As shown, a gate that reduces processing difficulty includes a valve stem 2, the outer surface of which is provided with trapezoidal threads, and also includes a gate body 1, a first positioning shaft 4, a second positioning shaft 5 and a connecting rod 3, The gate body 1 is an oval plate body, the outer edge of the gate body 1 is annularly provided with a wear-resistant layer 11, and the outward side of the gate body 1 is fixedly equipped with a sealing ring 12, and the number of the gate body 1 is two , the gate bodies 1 are set opposite to each other, the bottoms of the two gate bodies 1 are jointly hinged on the first positioning shaft 4, the upper hinged connecting rod 3 is at the lower end, the connecting rod 3 is a rectangular plate, and the second positioning shaft is a cylinder , the second positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com