Cleaning brush for narrow-mouth bottle

A technology for cleaning brushes and bottles, which is applied in the field of brushes and can solve the problems of inconvenient cleaning of the inner wall of narrow-mouthed containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

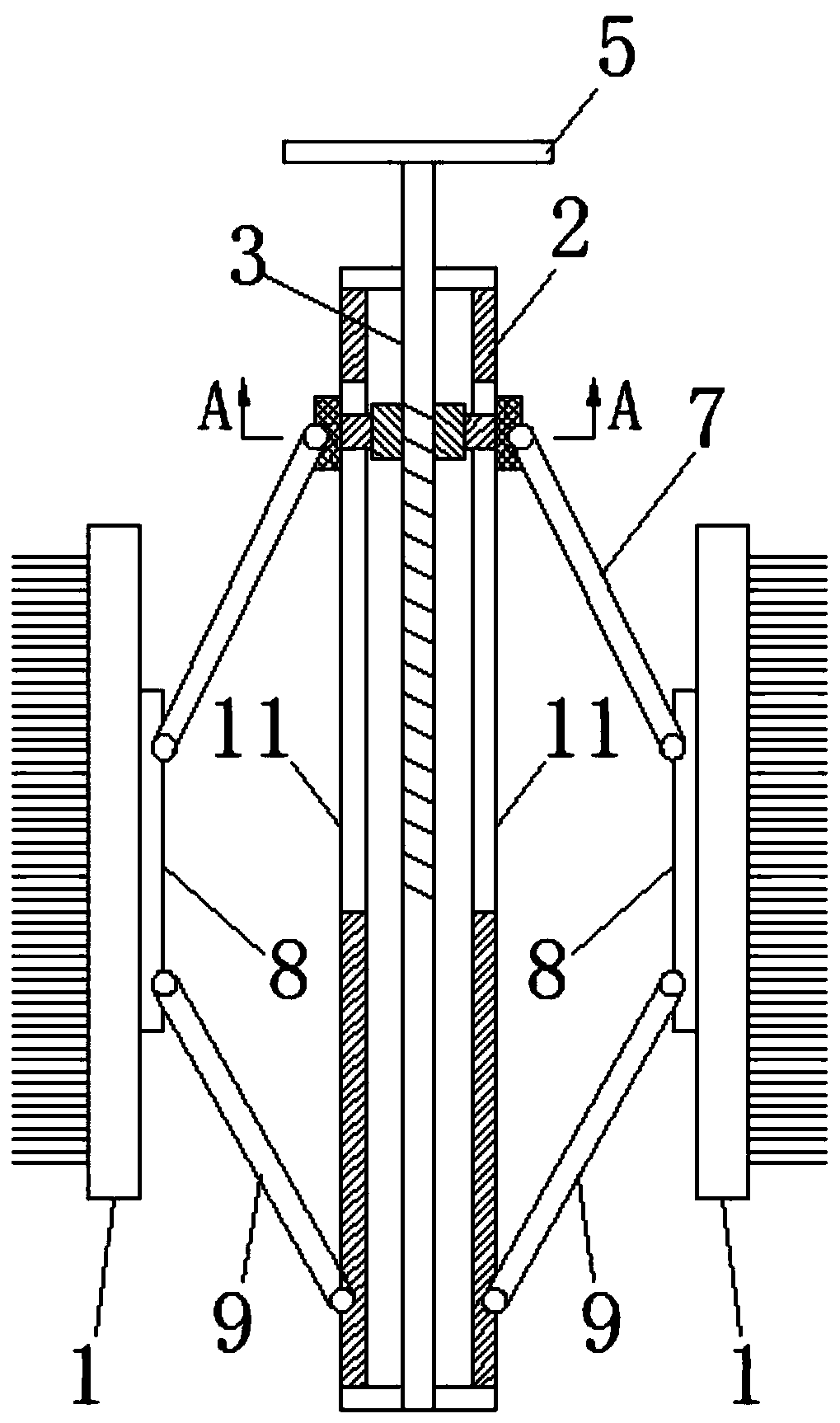

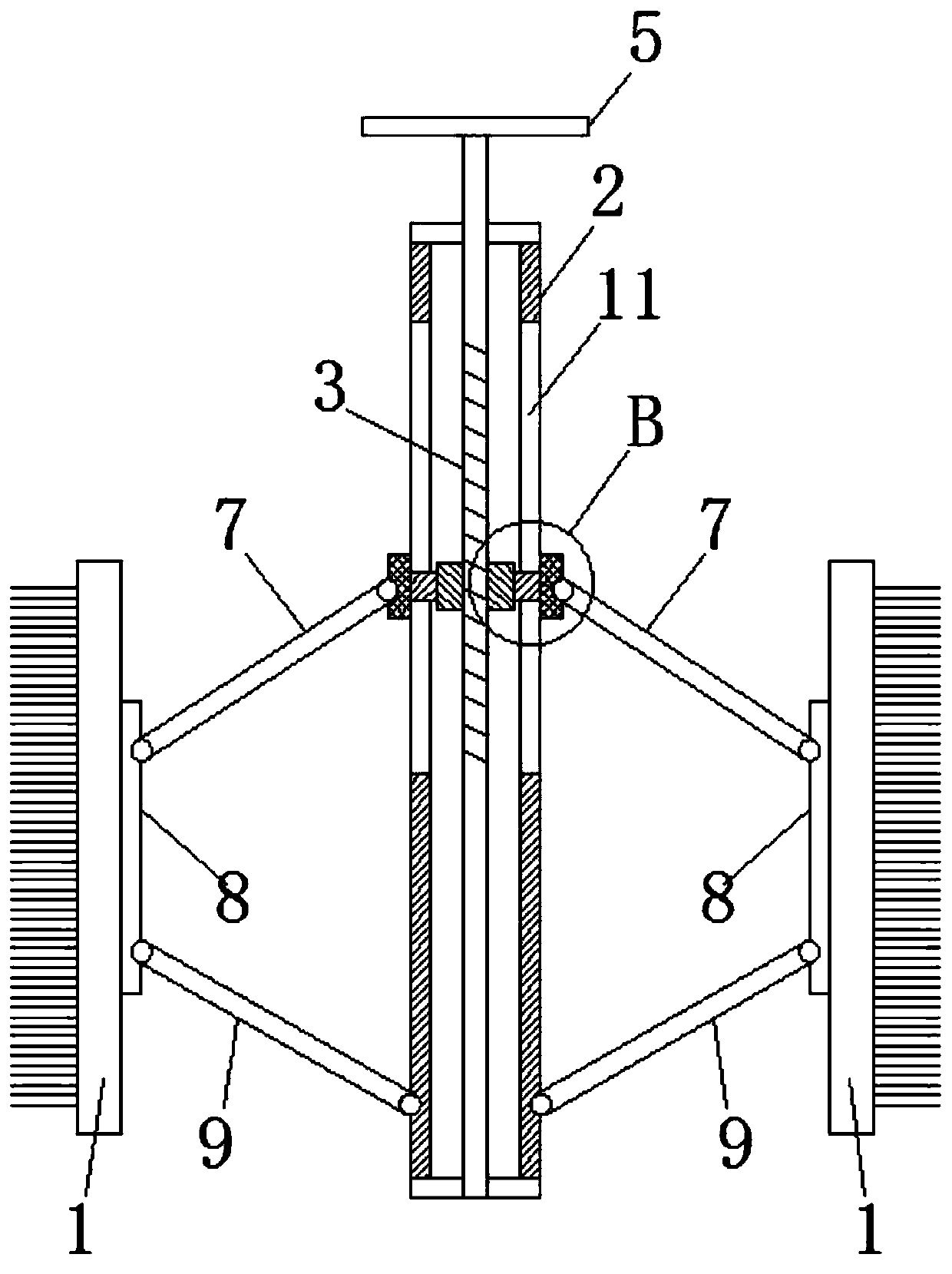

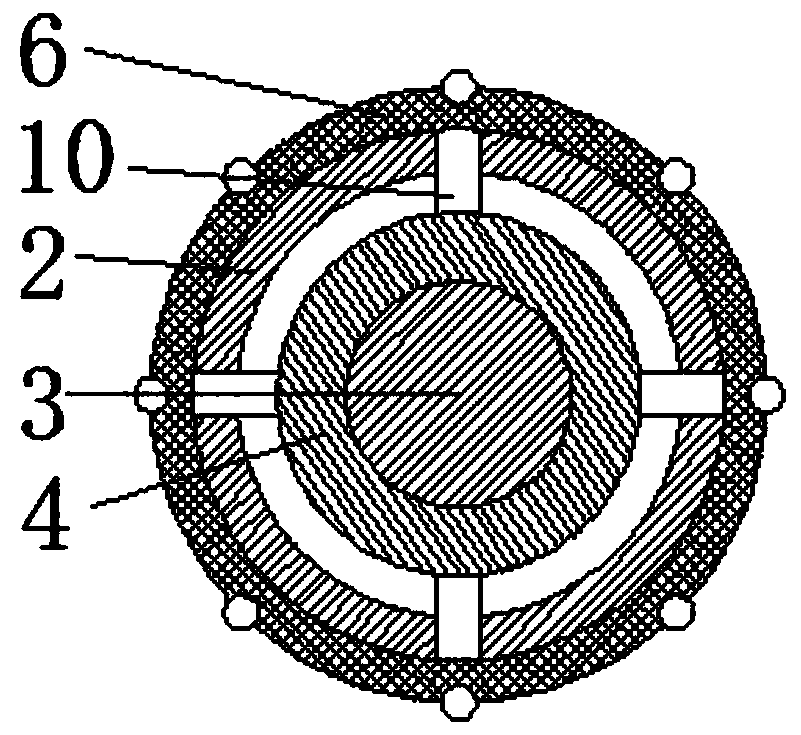

[0023] Such as Figure 1-4 As shown, a cleaning brush for narrow-mouth bottles includes a bracket and several brush bodies 1 installed on the bracket. The bracket includes an outer tube 2, an adjusting screw 3 and several adjusting mechanisms; the adjusting screw 3 is coaxially arranged outside Inside the tube 2, the adjusting screw rod 3 is rotationally connected with the outer tube 2, and the two are rotationally connected through the cooperation of the hole shaft, or are connected through a bearing; There is a handle 5 that is convenient for turning operation.

[0024] The adjustment mechanism includes a sliding seat 6, a first connecting rod 7, a brush mounting seat 8 and a second connecting rod 9. The sliding seat 6 is slidably connected to the outer wall of the outer tube 2, and the sliding seat 6 slides along the axial direction of the outer tube 2. The second One end (upper end) of a connecting rod 7 is hinged with the sliding seat 6, and the other end (lower end) is ...

Embodiment 2

[0032] It differs from Embodiment 1 in that: as Figure 5 As shown, in this embodiment, the adjustment mechanism includes two second connecting rods 9, and the two second connecting rods are parallel to each other. Such setting can ensure that the brush body mounting base 8 performs translational motion so that it is always kept vertical, that is, the brush body 1 is always kept vertical, thereby facilitating cleaning of narrow-mouth bottles of different sizes.

Embodiment 3

[0034] It differs from Embodiment 1 in that: as Figure 6 As shown, the axis of rotation (pin axis) at the hinge of the first connecting rod 7 and the brush body mount 8 coincides with the axis of rotation (pin axis) at the hinge of the second connecting rod 9 and the brush body mount 8 . In this embodiment, the first connecting rod 7 and the second connecting rod 9 are hinged at the same place of the brush body mounting seat 8, and are realized through the same pin shaft and pin hole. In this way, the brush body mounting base 8 and the brush body 1 installed on it can be rotated relative to the outer tube 2, thereby adapting to the cleaning work of the inner wall of narrow-mouth bottles of different shapes.

[0035] Correspondingly, the brush body mounting base 8 and the brush body 1 are made of flexible materials, such as rubber or cotton cloth, so as to improve the cleaning effect on narrow-mouth bottles with irregular inner walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com