Substrate cleaving device

A split and substrate technology, applied in the field of substrate split devices, can solve problems such as excessive bending of the substrate and damage to the surface of the substrate, and achieve the effect of preventing excessive bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

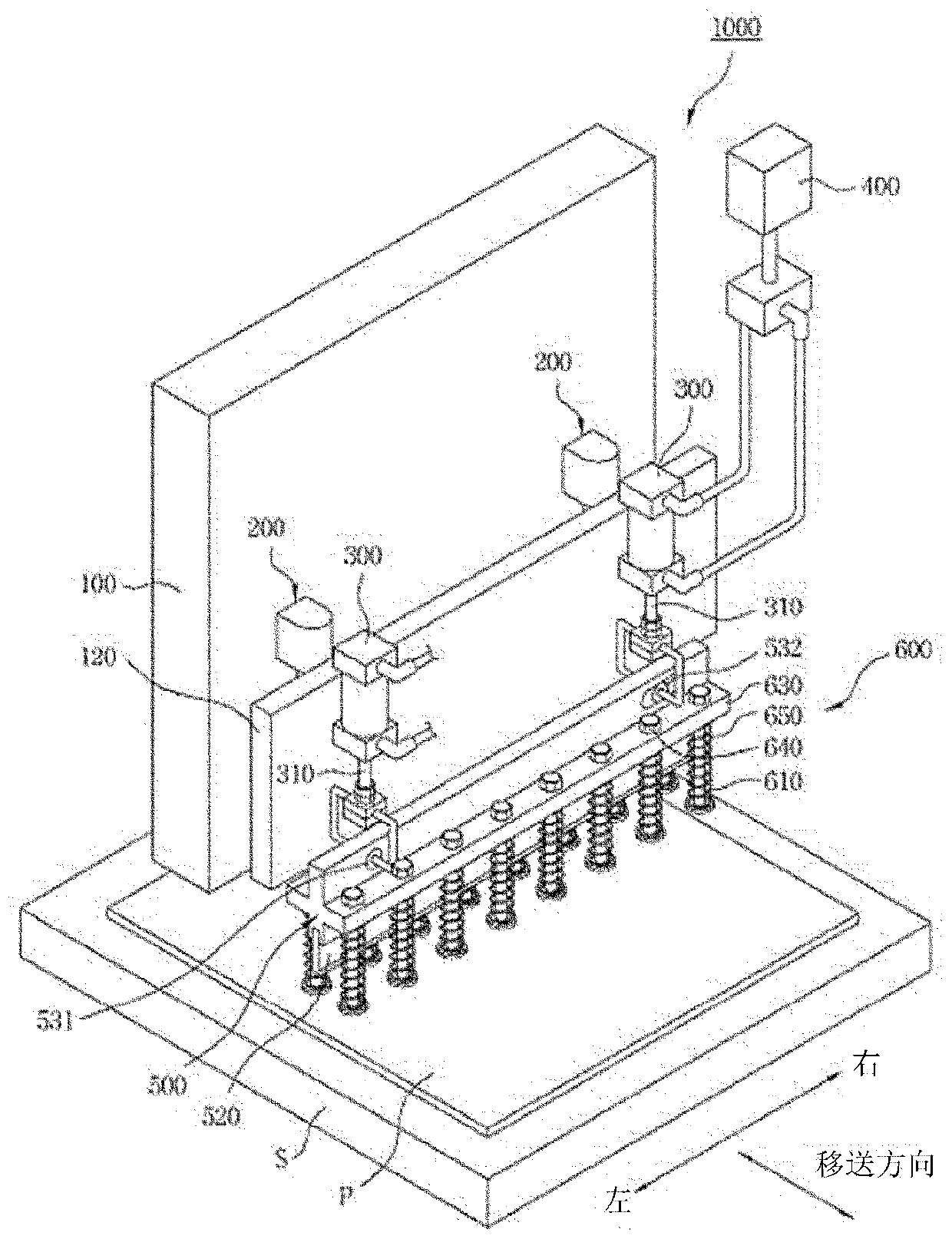

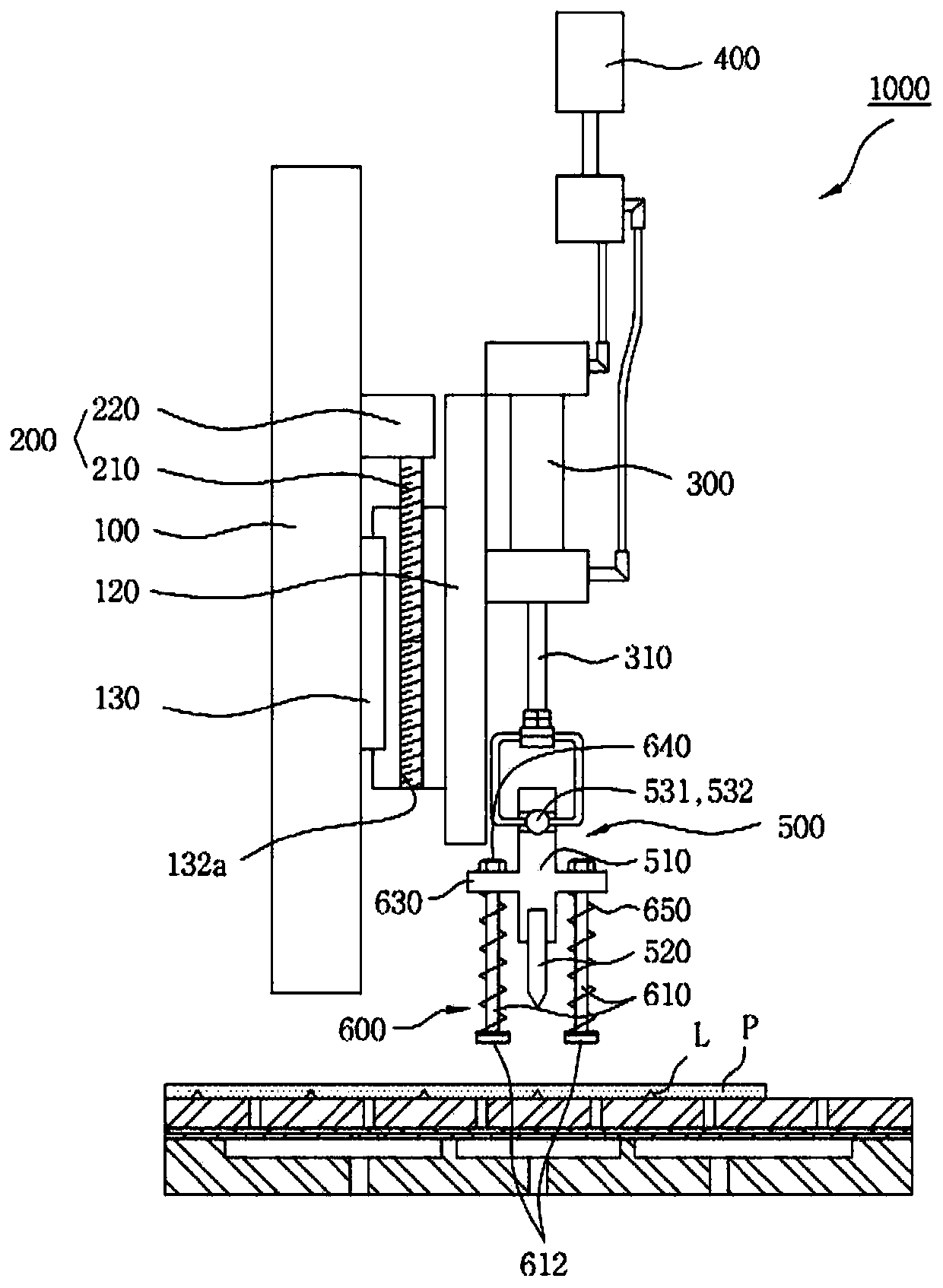

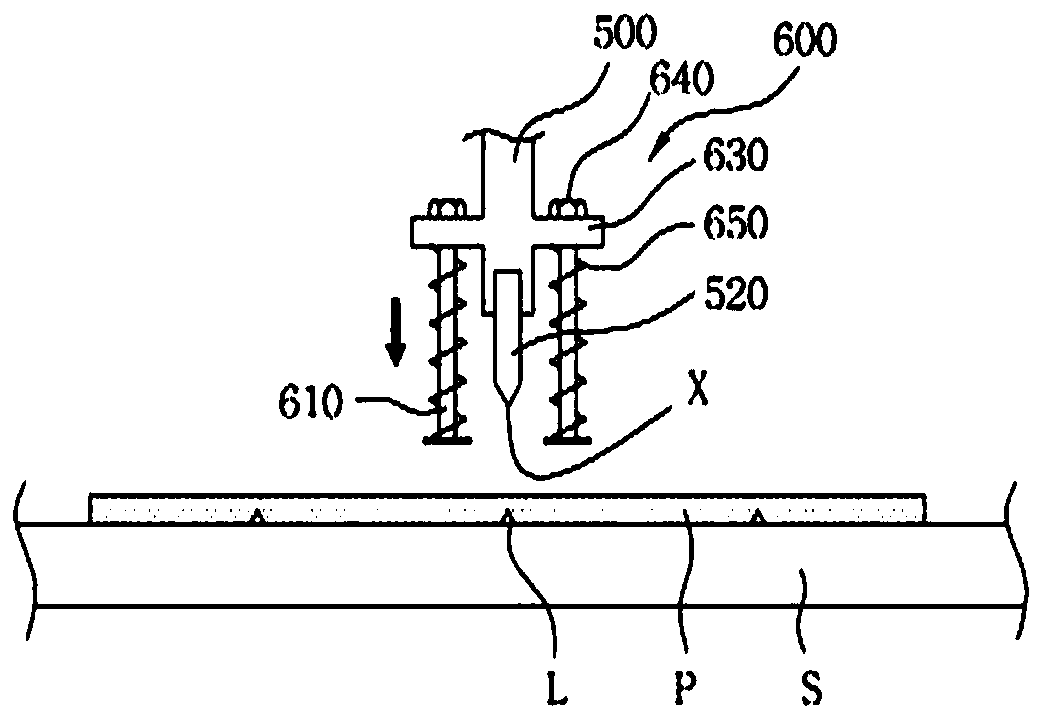

[0028] Hereinafter, the substrate splitting device in the embodiment of the present invention will be described with reference to the drawings.

[0029] Such as figure 1 and figure 2 As shown, the substrate splitting device 1000 in the embodiment of the present invention includes: a seat body 100 disposed above the loading table S supporting a substrate P; a transfer unit 200, which is respectively relative to the center of the substrate P in the transfer direction of the substrate P Are arranged on the left and right sides of the seat body 100; the cylinder 300 is arranged on the left and the right with respect to the center of the substrate P in the transfer direction of the substrate P, and the cylinder is moved up and down by the transfer unit 200; pressure adjustment The unit 400 is used to adjust the internal pressure of the cylinder 300; the split head 500, which is connected with the cylinder rod 310 of the cylinder 300, applies pressure to the surface of the substrate P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com