a tempered glass

A tempered glass and frame technology, which is applied in the field of tempered glass technical equipment, can solve the problems of affecting room temperature changes, can not well isolate the interference of the heat or cold of the outside air, etc., and achieve the effect of avoiding excessive heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

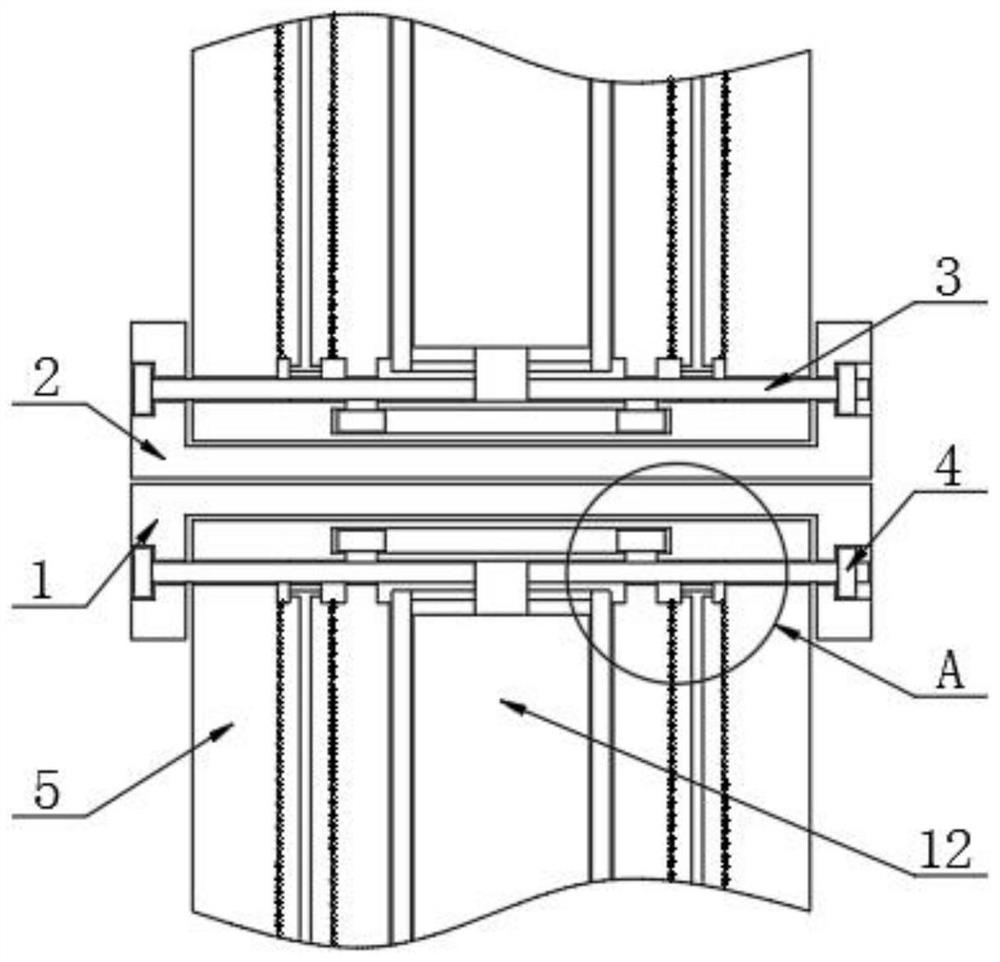

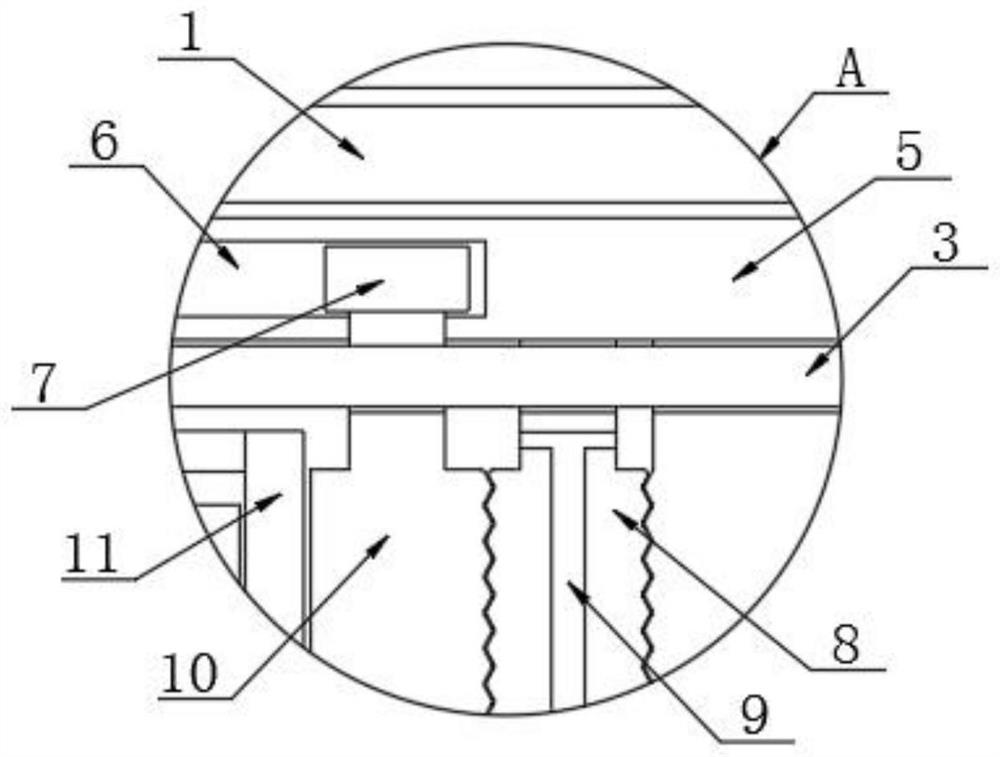

[0024] The present invention provides such Figure 1-4 The tempered glass shown includes a first frame 1 and a second frame 2, the inside of the first frame 1 and the second frame 2 are provided with a first screw 3, and one end of the first screw 3 is provided with a first Nut 4, the inside of the first frame 1 and the second frame 2 are provided with an outer cladding 5, the inside of the outer cladding 5 is provided with a chute 6, the inside of the chute 6 is provided with a sliding sleeve 7, and the outer cladding 5 is provided with a sliding sleeve 7. The inside of the layer 5 is provided with a heat dissipation layer 8, the inside of the heat dissipation layer 8 is provided with a diffusion groove 9, the inside of the heat dissipation layer 8 is provided with a slide plate 10, the inside of the slide plate 10 is provided with a buffer sheet 11, and the inside of the buffer sheet 11 is provided with There are 12 interlayers.

[0025] The effect of the technical solution...

Embodiment 2

[0027] A second screw 13 is provided between the first frame 1 and the second frame 2, and a second nut 14 is provided at one end of the second screw 13, and a second nut 14 is provided on the outside of the first frame 1 and the second frame 2. Raised strips, the second screw rod 13 runs through the raised strips and the second screw rod 13 is threadedly connected with the second nut 14. After matching the raised strips between the first frame 1 and the second frame 2, the second screw rod 13 Through the first frame 1 and the second frame 2 , the second nut 14 is threadedly connected with the second screw rod 13 , so that the first frame 1 and the second frame 2 are assembled.

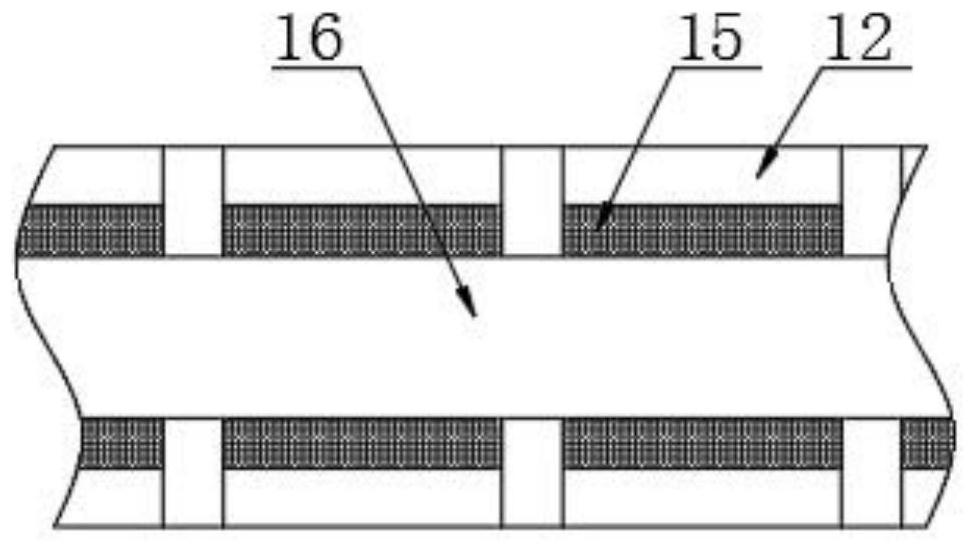

[0028] The inner side of the interlayer 12 is provided with a contraction layer 15, the inner side of the contraction layer 15 is provided with a liquid storage layer 16, and the surface of the interlayer 12 is provided with a leakage hole, and the leakage hole corresponds to the inner side of the buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com