A reaction feed temperature control device in coal tar hydrogenation

A technology of feed temperature and control device, which is applied in the field of coal tar hydrogenation, can solve the problems of unsatisfactory cooling, unfavorable coal tar processing, damage to the reactor, etc., and achieve the effect of easy cooling, simple control and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

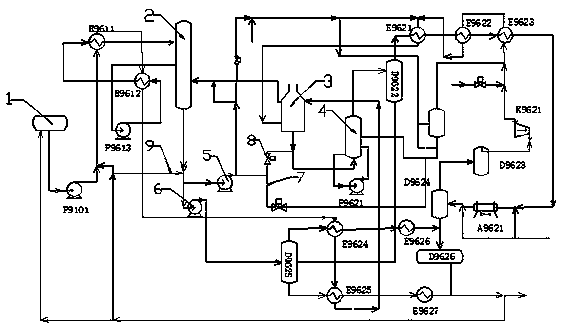

[0018] Such as figure 1 As shown, the present invention provides a reaction feed temperature control device in coal tar hydrogenation, comprising a tar tank 1, an atmospheric tower 2, a heating furnace 3 and a reactor 4, and the raw oil in the tar tank 1 passes through a tar pump After P9101 is boosted, the heat exchange temperature between heat exchanger E9611, heat exchanger E9612 and the oil in the middle section of atmospheric tower 2 rises to 88.5°C, and the heat exchange between heat exchanger E9624 and heat low gas separation, heat exchanger E9625 and heat low The oil separation heat exchange temperature rises to 240°C, then enters the convection chamber of the heating furnace 3 and the temperature rises to 260°C, and then enters the atmospheric tower 2 for thermal dehydration; the heavy oil at the bottom of the atmospheric tower 2 is connected to the bottom of the atmospheric tower 2. The material pump 5 is pressurized to 16.8MPa(g), mixed with the boosted vulcanizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com