A Measuring Device for Turbine Blade Rotating Dynamic Airflow Exciting Force

A technology of airflow excitation force and measurement device, which is applied in the directions of safety devices, engine components, machines/engines, etc., can solve the analysis of the forced vibration phenomenon of difficult-to-rotate blades, cannot accurately obtain the position and amplitude of the excitation force, and cannot accurately The size and action position of the airflow exciting force can be obtained in a precise manner, so as to improve the accuracy and reduce the friction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

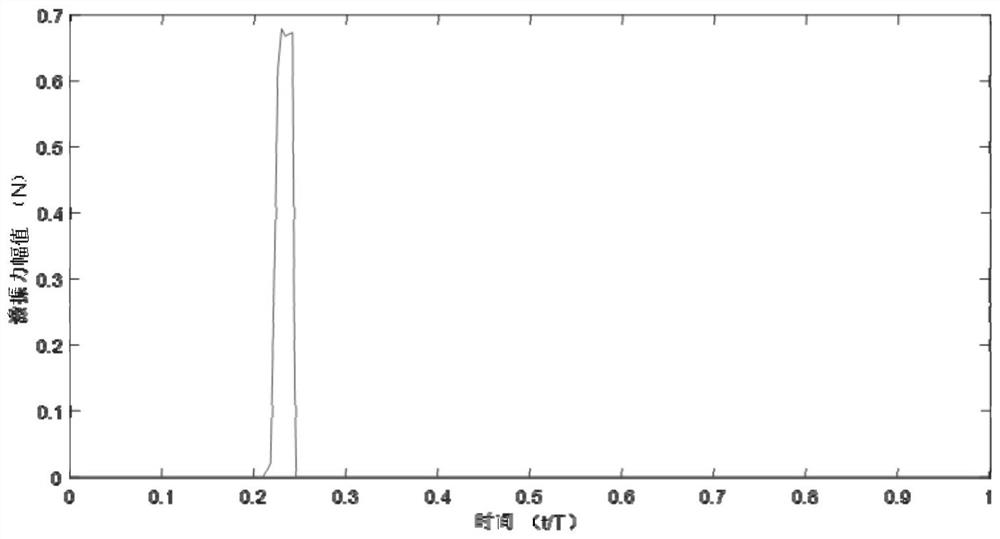

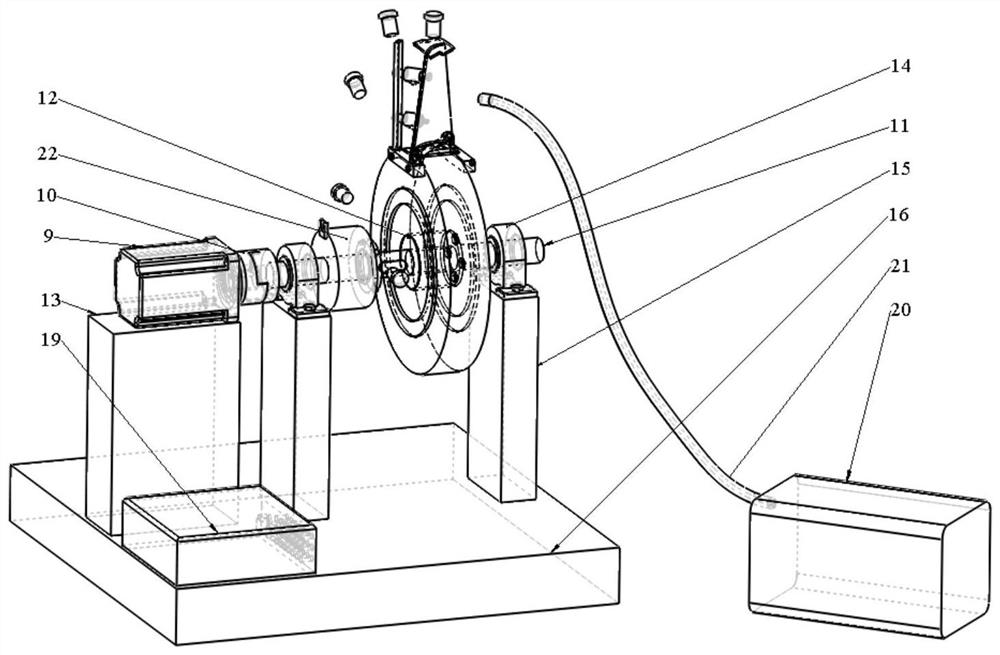

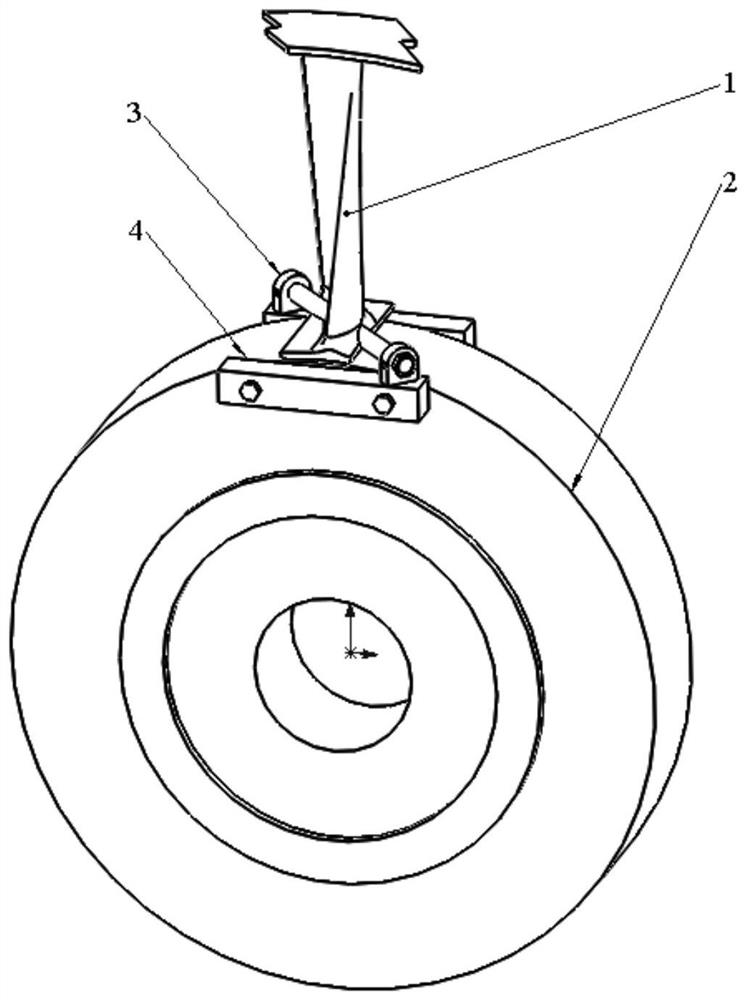

[0036] see figure 1The present invention provides a turbine blade rotation dynamic airflow excitation force measurement device, including a blade disk system, a driving device, an airflow excitation generation device, an excitation force measurement and data acquisition device, a blade tip timing vibration measurement device and a foundation Bench. In the driving device, the servo motor 9 drives the main shaft 11 to rotate at a speed of 60 rpm through the coupling 10 , and the torque is transmitted between the main shaft 11 and the wheel 2 through the expansion sleeve 12 . The main shaft 11 is supported by two bearing blocks 14 , the servo motor 9 and the bearing blocks 14 are installed on the motor mounting platform 13 and the bearing seat mounting platform 15 respectively, and the two mounting platforms are fixed on the base 16 . When it is necessary to introduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com