A shrinking machine

A technology of shrinking machine and elastic belt, which is applied to the shrinking machine and shrinking part of the fabric. It can solve the problems of increasing maintenance costs, machine failure, and increasing production costs, and achieves the effect of optimizing the degree of fabric shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

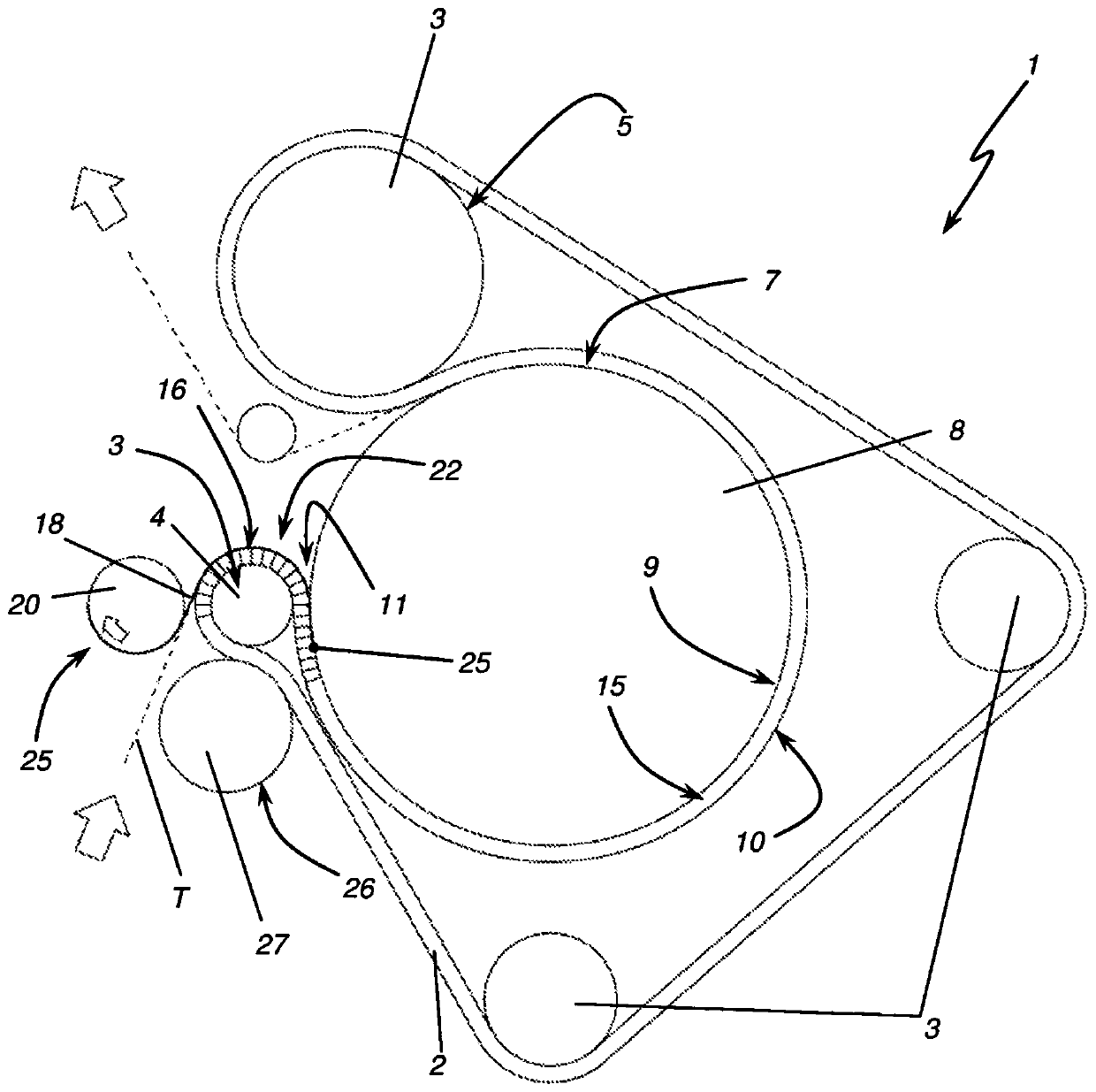

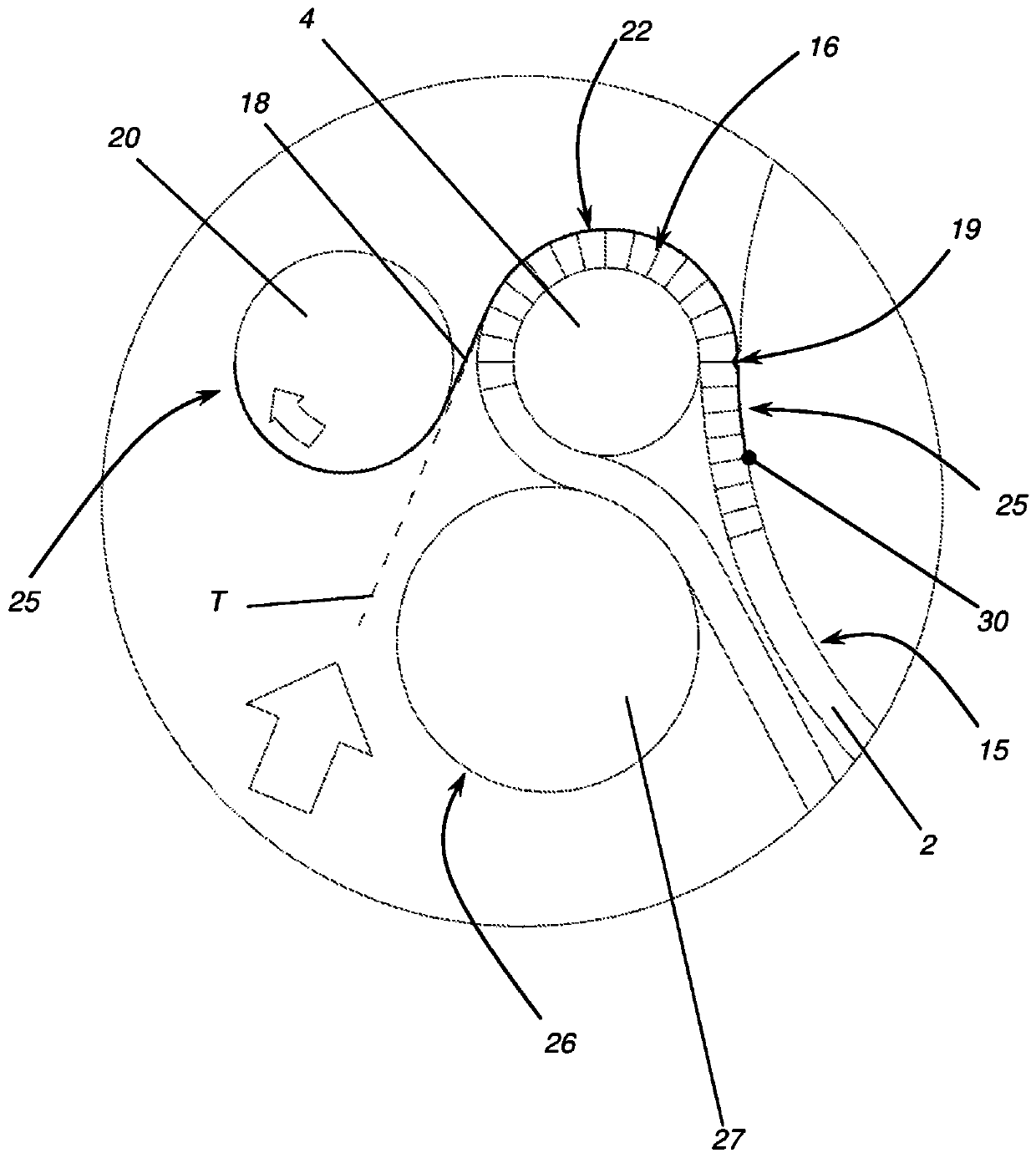

[0034] Referring to the attached drawings, especially figure 1 and figure 2 , the shrinking machine 1 for fabric T is described here.

[0035] The shrinking machine 1 comprises an elastic belt 2 with which the fabric T to be shrunk is placed in contact. The elastic band 2 is wound between rollers 3 to form a closed loop. The drum 3 includes an inlet drum 4 and an outlet drum 5 . The entry roller 4 corresponds to the point at which the fabric T is brought into contact with the elastic belt 2 ; the exit roller 5 marks the point of maximum travel of the fabric T on said elastic belt 2 . On reaching the exit drum 5, the fabric T is removed from the elastic belt 2 for further processing steps.

[0036] In order to shrink the fabric T, the shrinking machine 1 comprises a centering part 7 arranged between the inlet drum 4 and the outlet drum 5 and adjoining the elastic belt 2 . The outer surface 8 of the centering part 7 forms an extension 9 which together with a corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com