Saline-alkali soil conditioner

A soil improver and saline-alkali land technology, applied in the direction of soil conditioning materials, applications, organic fertilizers, etc., can solve the problems of poor improvement effect and poor water retention, and achieve the effect of improving water retention and moisturizing effect, increasing fertility, and reducing soil alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

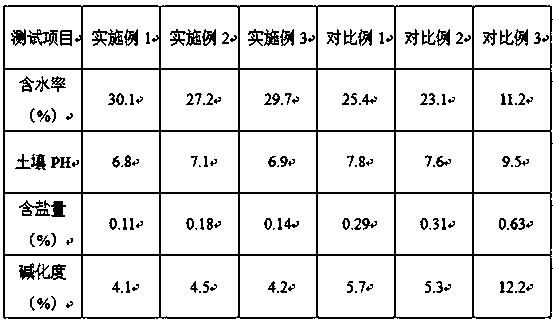

Examples

preparation example Construction

[0030] A method for preparing a water-retaining substance, comprising the steps of:

[0031] (1) Mix carbomer and water in a container at a mass ratio of 1:15~25, stir and mix at 500~800r / min for 25~50min, let stand at room temperature for swelling for 3~5h, stir at 400~600r / min for 45 ~60min, to obtain carbomer solution, according to parts by weight, sequentially take 8~15 parts of rubber material, 2~5 parts of glucose, 15~25 parts of carbomer solution, 40~60 parts of water, first take rubber material, glucose Mix and pour into a mortar, grind for 30-50 minutes, then add carbomer solution and water, let it stand for swelling at room temperature for 4-6 hours, heat to dissolve and stir for 15-25 minutes at 55-70°C, 700-1000r / min speed conditions, Discharge, get mixed glue;

[0032](2) Mix wheat germ, ethephon, and water at a mass ratio of 3:0.01:20~35, let stand at room temperature and soak for 4~8 hours, filter to obtain pretreated germ, and take the pretreated germ and free...

Embodiment 1

[0039] Pretreatment of pig aggregates: take pig bones and wash them with water for 3 times, take the washed pig bones and mix them with water at a mass ratio of 1:6, cook and degrease at 115°C for 40 minutes, cool naturally to room temperature, discharge, and crush in a grinder 200 mesh sieve, collect the sieved particles, count by mass parts, take 20 parts of sieved particles, 6 parts of potatoes, 2 parts of Lactobacillus bulgaricus powder, 5 parts of glucose, 1 part of NaH 2 PO 4 , 100 parts of water, fermented at 28°C for 2 days on a shaking table at 180r / min, and then sterilized at 121°C for 15 minutes to obtain the fermented material. The fermented material was vacuum evaporated at 65°C to 25% of the original volume to obtain Preprocess aggregates.

[0040] Film-forming solution: mix dopamine hydrochloride, aniline, and deionized water at a mass ratio of 3:0.2:18 to obtain a film-forming solution.

[0041] Excipients: Glycerin and sodium dodecylbenzenesulfonate are mixe...

Embodiment 2

[0055] Pretreatment of pig aggregates: take pig bones and wash them with water for 4 times, take the washed pig bones and mix them with water at a mass ratio of 1:8, cook and degrease under high pressure at 125°C for 50 minutes, cool naturally to room temperature, discharge the materials, and crush them in a grinder 200 mesh sieves, collect the sieved particles, by mass parts, get 32 parts of sieved particles, 9 parts of potatoes, 3 parts of Lactobacillus bulgaricus powder, 8 parts of glucose, 2 parts of NaH 2 PO 4 , 110 parts of water, fermented and cultivated at 31°C for 3 days in a shaking table at 200r / min, and then sterilized at 121°C for 23 minutes to obtain the fermented material. The fermented material was vacuum evaporated at 62°C to 32% of the original volume, namely Preprocess aggregates.

[0056] Film-forming solution: Mix dopamine hydrochloride, aniline, and deionized water at a mass ratio of 3:0.3:22 to obtain a film-forming solution.

[0057] Excipients: Gly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com