Production equipment and production method of edge slotted mineral wool board

A technology of production equipment and production method, which is applied in the field of production equipment for edge slotted mineral wool boards, can solve problems such as large footprint and complex structure, and achieve the effects of improving production efficiency, overcoming technical defects, and optimizing structural composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

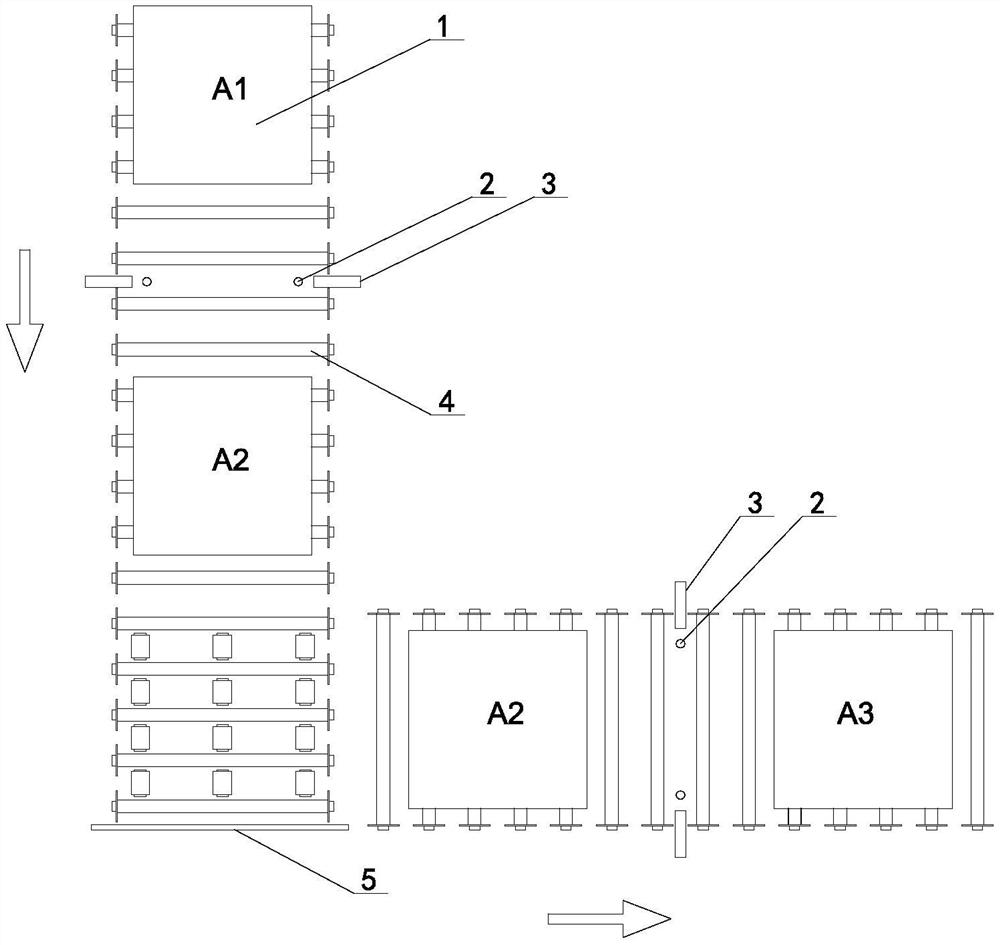

[0049] like figure 1 As shown, Embodiment 1 of the present invention provides a production equipment for edge grooved mineral wool boards, including a tenoning tool unit, a slotting tool unit, and a conveying workbench. The conveying workbench includes a first conveying work whose conveying directions are perpendicular to each other. table and the second conveying table.

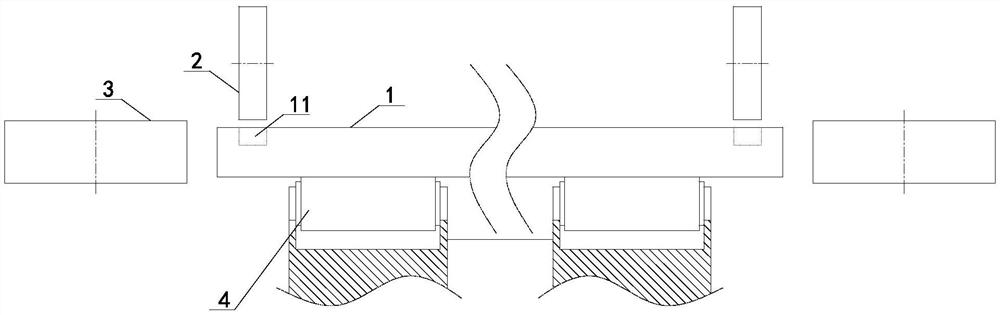

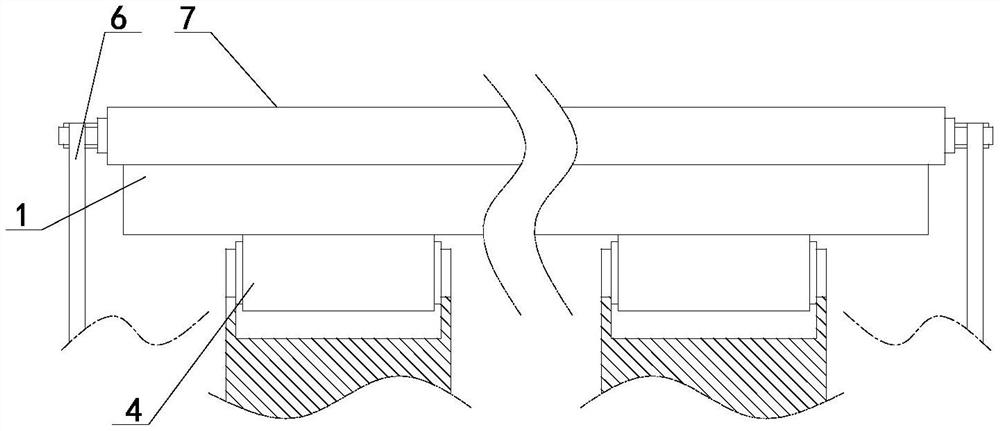

[0050] like figure 2 As shown, the tenoning cutter unit in this embodiment is arranged horizontally, and the tenoning cutter unit is used to complete the opening operation of the tenon edge of the mineral wool board 1; the slotting cutter unit in this embodiment is vertically arranged, and the slotting cutter unit is used for The opening operation of the groove 11 of the mineral wool board 1 was completed.

[0051] to combine figure 1 , figure 2 As shown, the tenoning cutter unit in this embodiment is provided with two groups, one group is arranged on the first conveying table, and the other group is a...

Embodiment 2

[0075] Embodiment 2 of the present invention provides a kind of production method of edge slotted mineral wool board, comprises the following steps:

[0076] Cut the mineral wool board to the target size;

[0077] Set the decorative surface of the mineral wool board upwards on the first conveying workbench;

[0078] Complete the tenon opening operation of the first group of opposite sides of the mineral wool board through the tenoning tool unit, and complete the groove opening operation of the first group of opposite sides of the mineral wool board through the slotting tool unit;

[0079] Continue to convey along the first conveying workbench, and convey to the second conveying workbench;

[0080] The tenon opening operation of the second group of opposite sides of the mineral wool board is completed by the tenoning cutter unit, and the groove opening operation of the second group of opposite sides of the mineral wool board is completed by the slotting cutter unit.

[0081] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com