Self-adaptive dynamic vortex plate eccentric mechanism

An eccentric mechanism and moving scroll technology, applied in the field of compressors, can solve the problems of increased electrical compatibility, insufficient method unloading, complex control structure, etc., to reduce balance time, save preparation time, and realize radial flexible adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

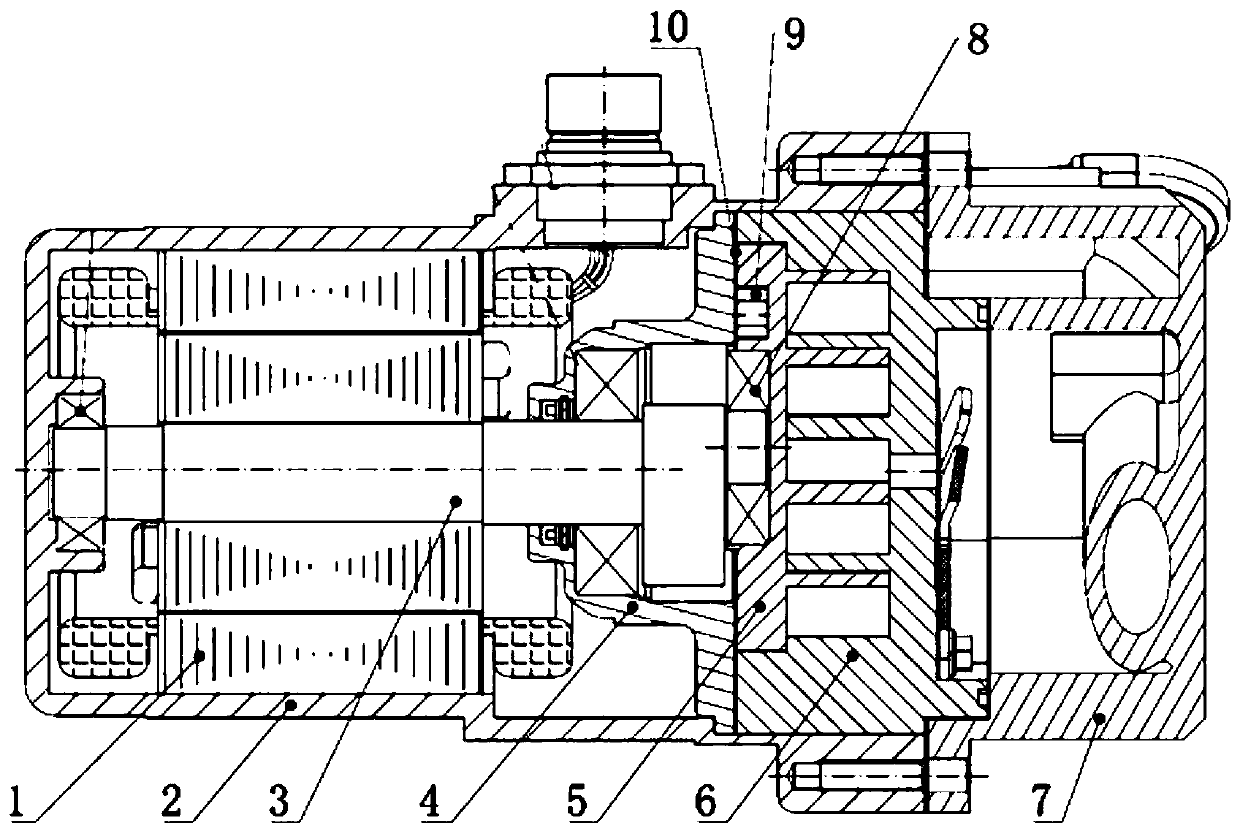

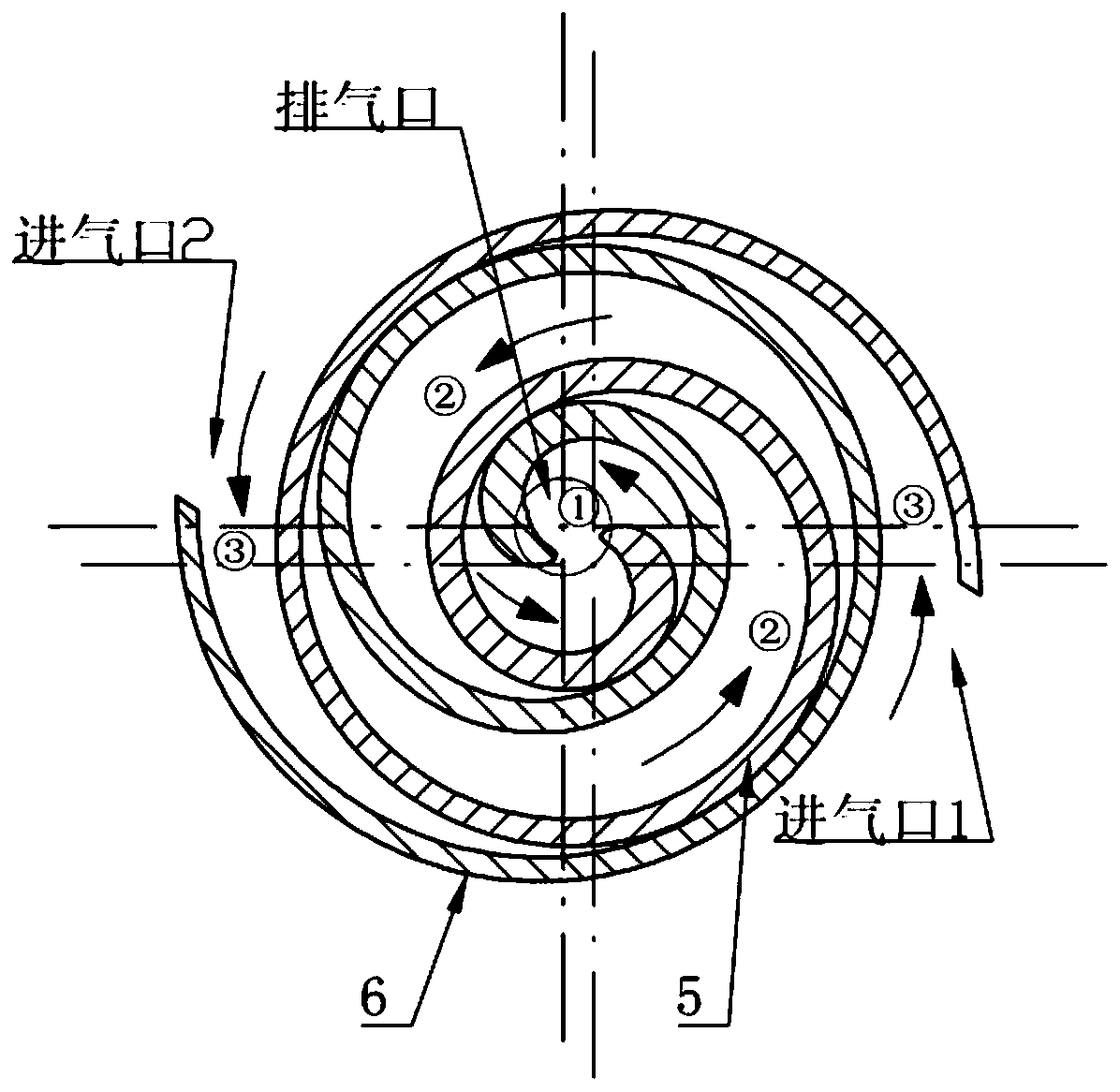

[0035] An adaptive movable scroll eccentric mechanism is provided, including a transmission shaft assembly (3), a movable scroll and a fixed scroll; the movable scroll is a movable scroll of a scroll compressor, and the fixed scroll is The static scroll of the scroll compressor;

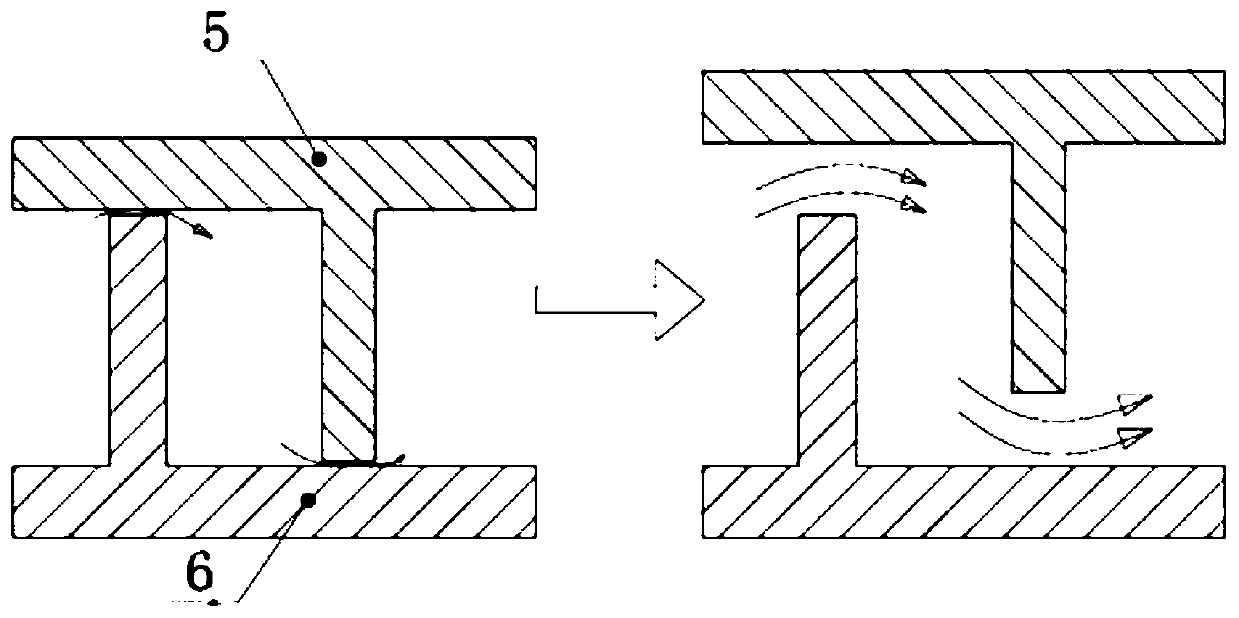

[0036] The drive shaft assembly (3) includes a drive shaft, an elastic element and a slider;

[0037] The end of the transmission shaft has a first space, the inner end of the slider is located in the first space, the slider can slide radially in the first space, an elastic element is arranged between the slider and the first space, and the transmission The slider is at the first eccentric position when the shaft is at rest, and the centrifugal force enables the slider to slide radially outward against the spring force to the second eccentric position when the transmission shaft is rotating; the first eccentric position is closer to the second eccentric position The rotation center of the transmissi...

Embodiment 2

[0042] An adaptive movable scroll eccentric mechanism is provided, including a transmission shaft assembly (3), a movable scroll and a fixed scroll; the movable scroll is a movable scroll of a scroll compressor, and the fixed scroll is The static scroll of the scroll compressor;

[0043] The drive shaft assembly (3) includes a drive shaft, an elastic element and a slider;

[0044]The end of the transmission shaft has a first space, the inner end of the slider is located in the first space, the slider can slide radially in the first space, an elastic element is arranged between the slider and the first space, and the transmission The slider is located at the first eccentric position when the shaft is at rest, and the centrifugal force enables the slider to slide radially outward against the spring force to the second eccentric position when the transmission shaft is rotating; the first eccentric position is closer to the second eccentric position The center of rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com