Method for replacing producing well shaft casing pipe

A technology for producing oil wells and casings, which is applied to casings, drill pipes, drilling equipment, etc., can solve the problems of limited reverse opening depth, small size, and many construction steps, so as to improve sealing, improve reliability, and prevent blowout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

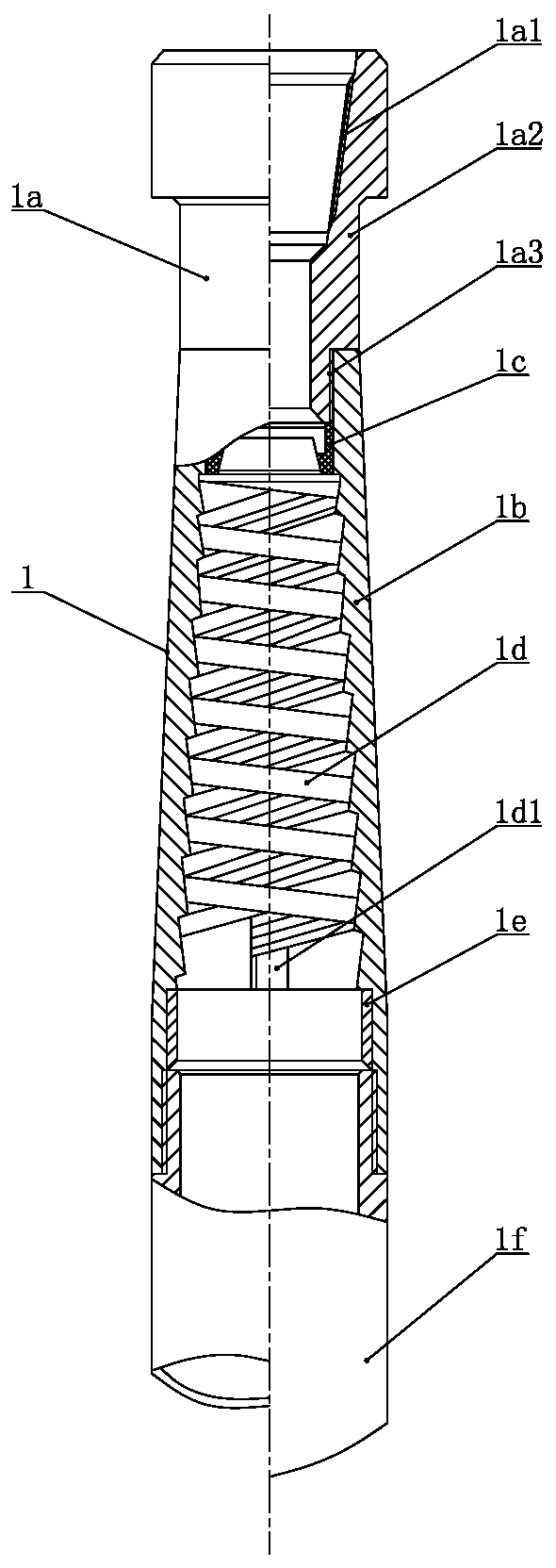

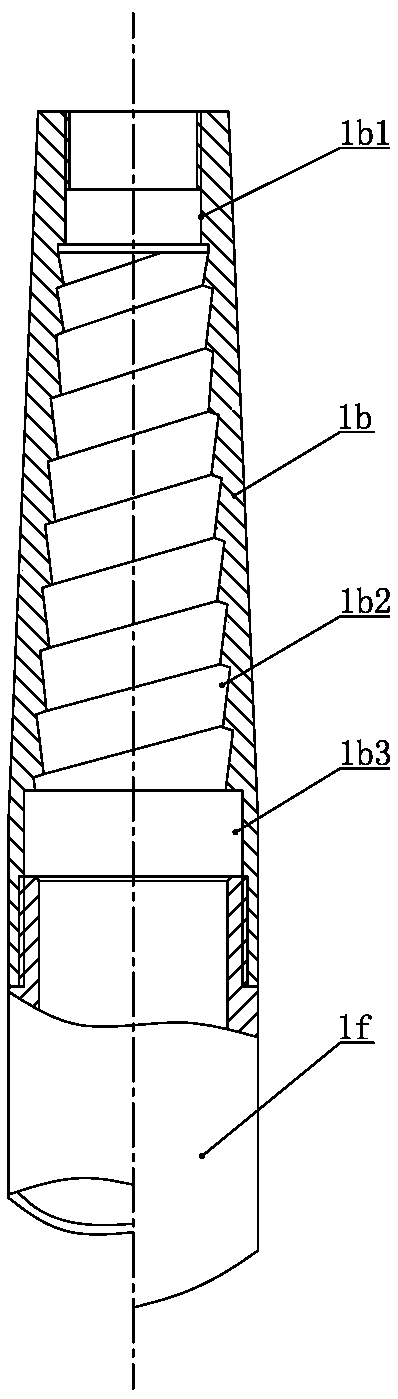

[0028] The operating tools used in the present invention include a downhole fishing tool 1 , a sleeve milling shoe 2 and an external butt joint cementing tool 3 .

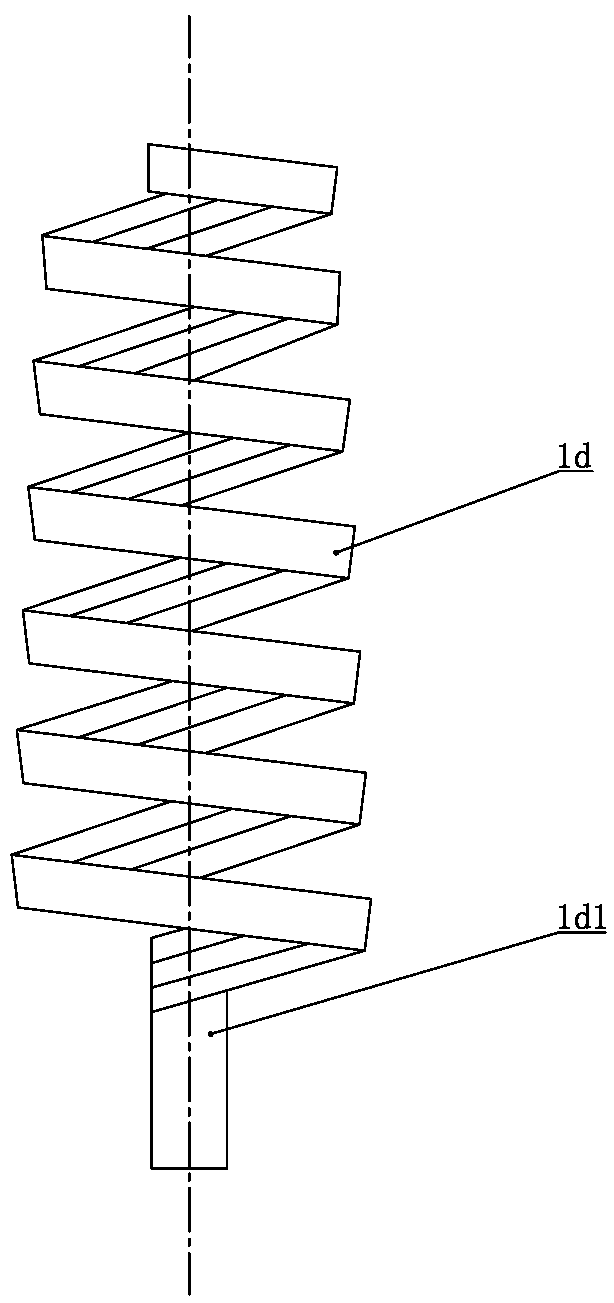

[0029] Such as Figure 1 to Figure 4 As shown, the downhole fishing tool 1 includes a conical overshot 1b, the upper port of the conical overshot 1b is screwed with a slip joint 1a, the lower end of the overshot is screwed with a standard guide shoe 1f, and the conical overshot 1b Slips are installed in the inner cavity, A-type packing 1c is installed on the upper end of the slips, and a control ring 1e is installed on the lower end of the slips. The inclination angle of the busbar of the outer wall of the conical overshot 1b relative to the axis of the conical overshot is 2°. And the inner diameter of the upper port of the conical overshot is 12mm smaller than the inner diameter of the lower port; the inner wall of the conical overshot 1b is provided with a conical spiral slip groove 1b2, and the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com