Hydraulic-pressure power device and pump thereof

A hydraulic power device and pump body technology, which is applied to liquid fuel engines, pumps, rotary piston type/oscillating piston type pump components, etc., can solve the problems of increasing the starting load of the motor, large starting load, and large motor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

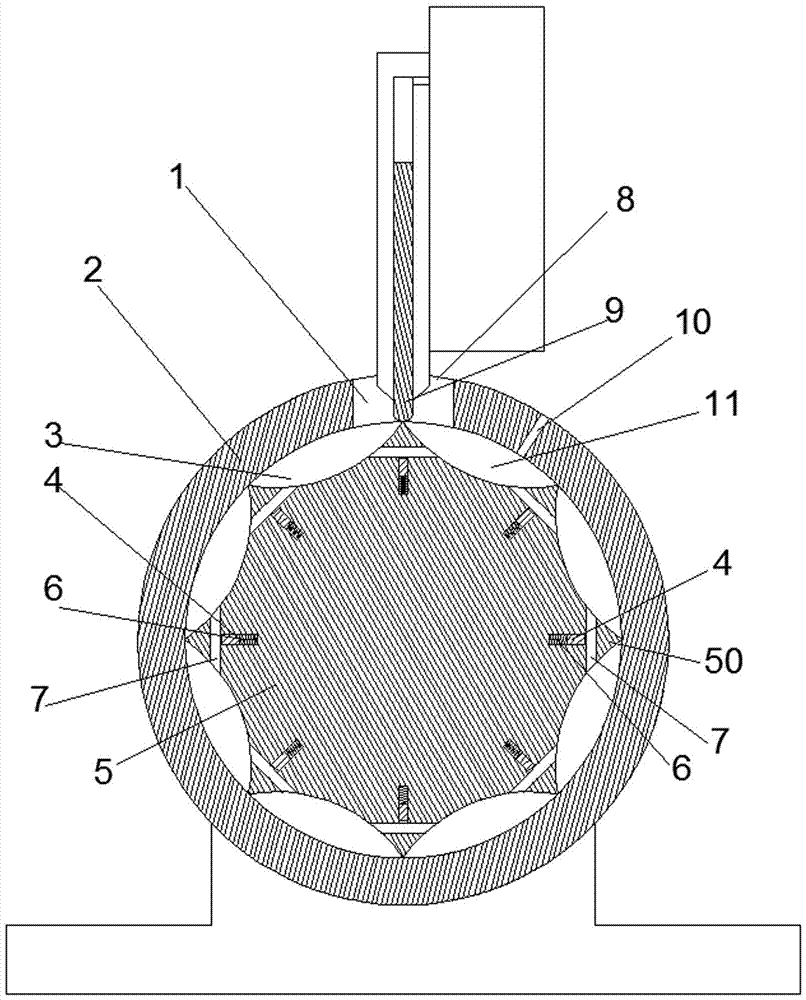

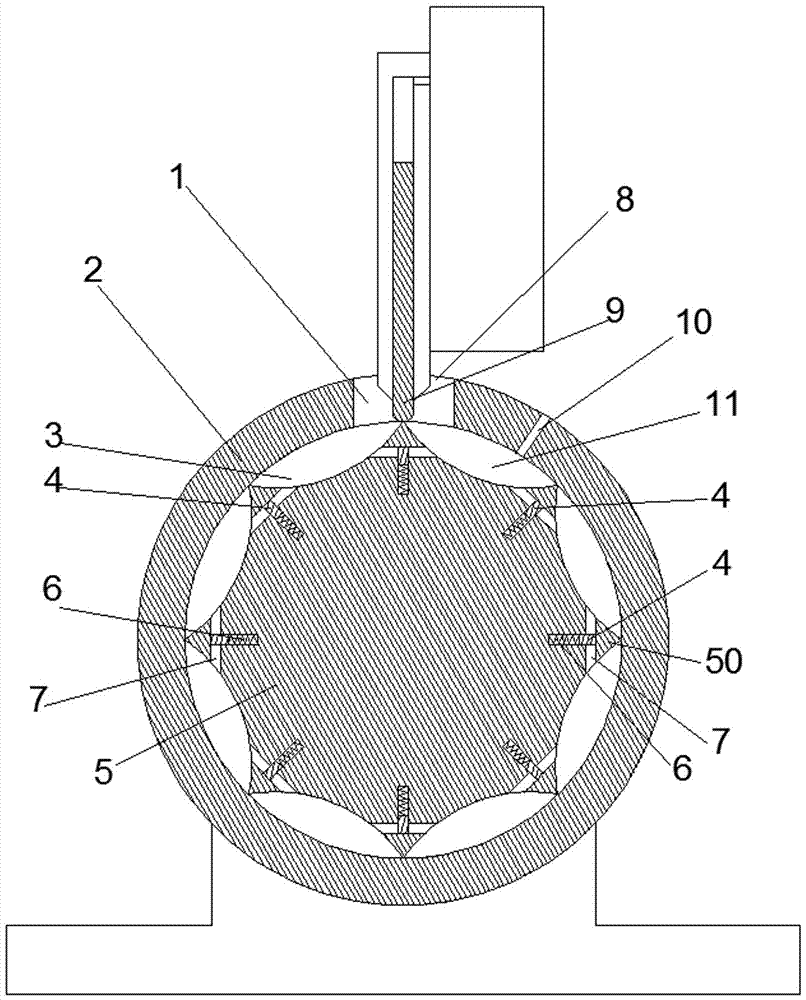

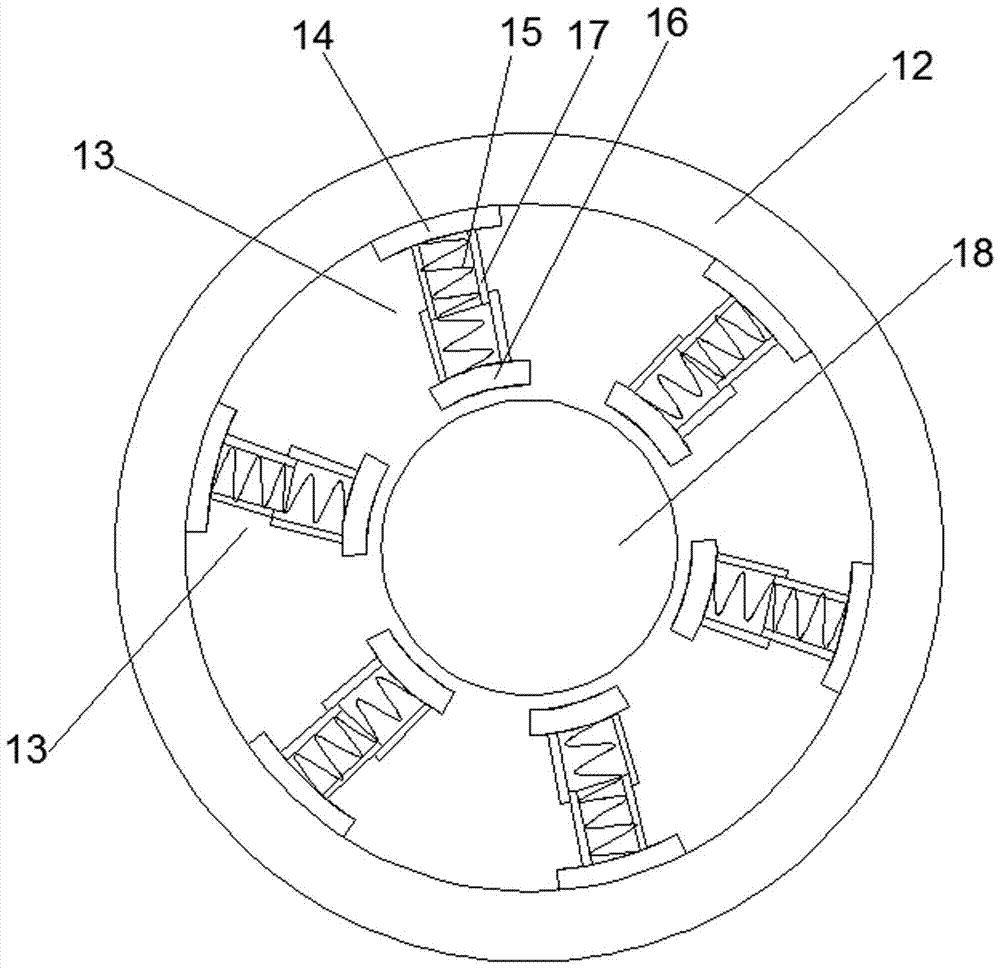

[0019] Examples of hydraulic power units are Figure 1~7 Shown: comprise motor 37 and pump 36, and pump 36 comprises the pump body 2 that has cylindrical hole inner cavity, is provided with the rotor 5 that rotation axis extends along the front-back direction in pump body 2, and the cross-section of rotor is polygonal structure, and Each side is in a concave arc shape, and a convex rib 50 extending along the front and back directions that is tangent to the cylindrical hole is formed between two adjacent sides, and the pump body is provided with a liquid inlet hole separated by a partition 9 8 and the liquid outlet hole 1, the partition 9 can move back and forth along the radial direction of the rotor, and the inner end of the partition 9 is slidingly and push-fitting with the outer peripheral surface of the rotor 5 . Each rib 50 is provided with an oil guide channel 7 connecting both sides of the rib in the circumferential direction. The rotor is guided and moved along the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com