Range hood with sliding door type smoke deflector and manufacturing method thereof

A technology for range hoods and smoke deflectors, which is applied in the direction of oil fume removal, heating methods, household stoves/stoves, etc. It can solve problems that affect the working efficiency and service life of range hoods, the entry of dust and impurities, and the inability of the smoke guides to be closed. , to achieve the effect of improving oil fume adsorption efficiency, preventing smoke escape, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

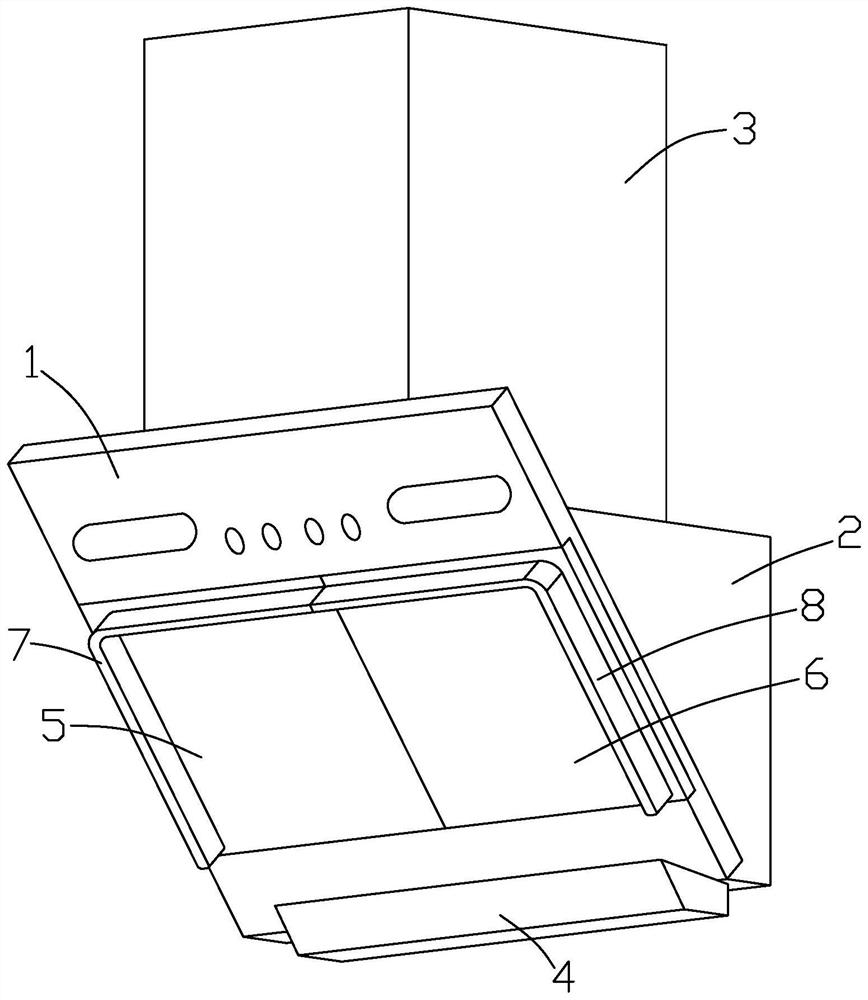

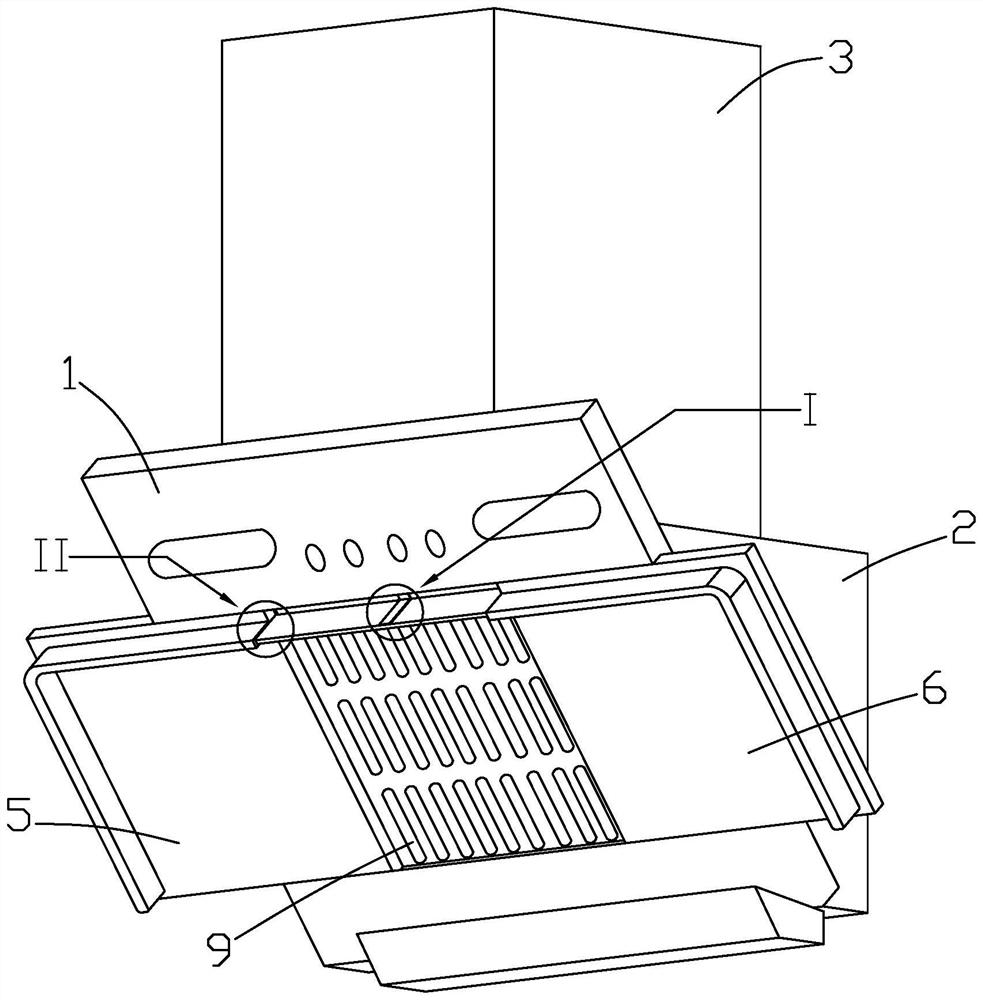

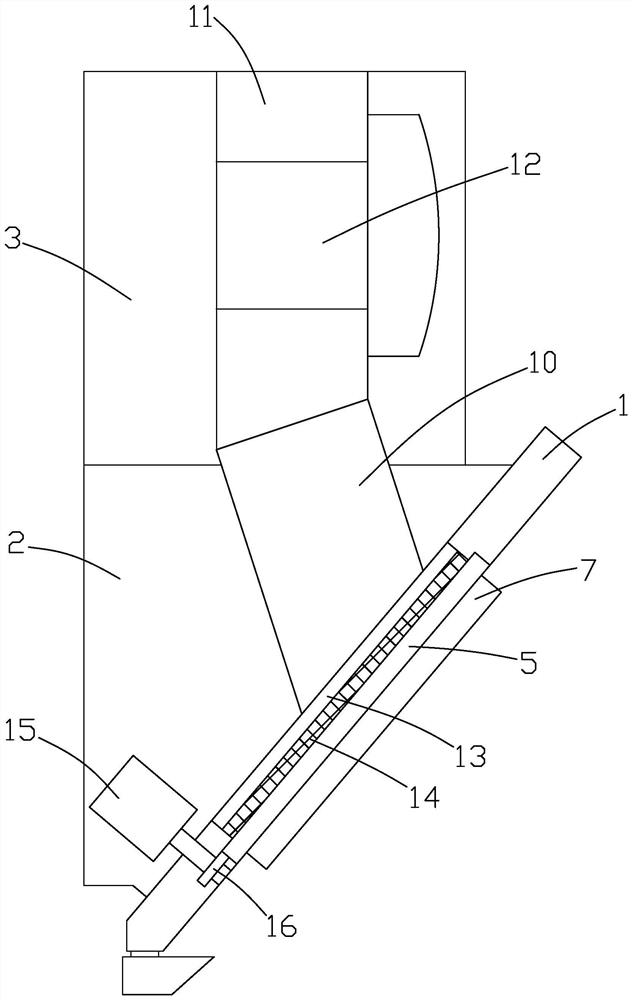

[0054] Such as Figure 1 to Figure 6 As shown, it is a range hood with a sliding door type smoke deflector in the present invention, including a panel 1, a positioning box 2 and a smoke exhaust box 3, the rear side of the panel 1 is connected to the smoke exhaust box 3 through the positioning box 2, and the panel The front side of 1 is provided with a first smoke guide plate 5, a second smoke guide plate 6 and a smoking plate 9, the first smoke guide plate 5 and the second smoke guide plate 6 are connected to the panel 1 through a horizontal movement mechanism, and are located at The outside of the smoking plate 9, the horizontal movement mechanism includes two synchronous motors 15, the two synchronous motors 15 are symmetrically fixedly connected to the bottom of the positioning box 2, the synchronous motors 15 are connected with gears 16 through the rotating shaft, the first smoke guide plate 5 and the second The bottom surface of the smoke guiding plate 6 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com