An automatic grabbing and lifting device in a reactor

A reactor and automatic technology, applied in the field of reactor material irradiation, can solve problems such as debris brought into the reactor, potential safety hazards of the reactor, and health hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

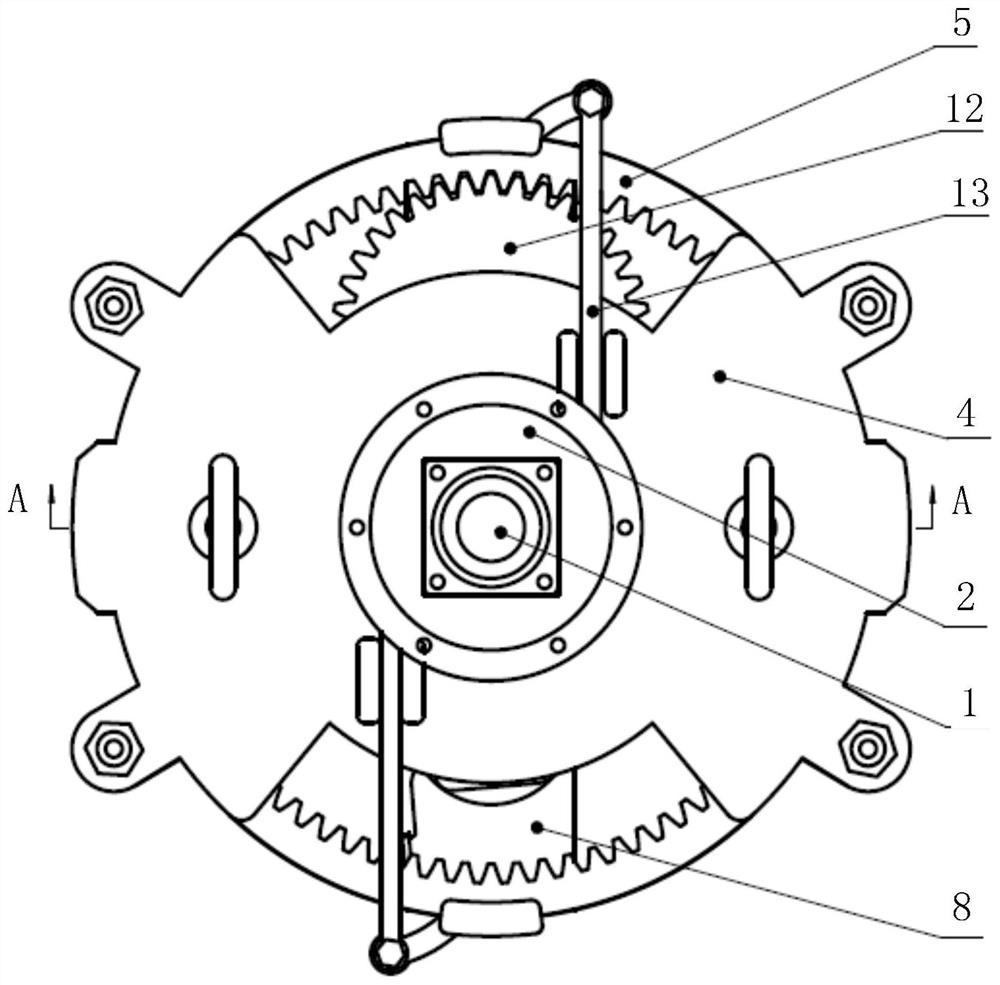

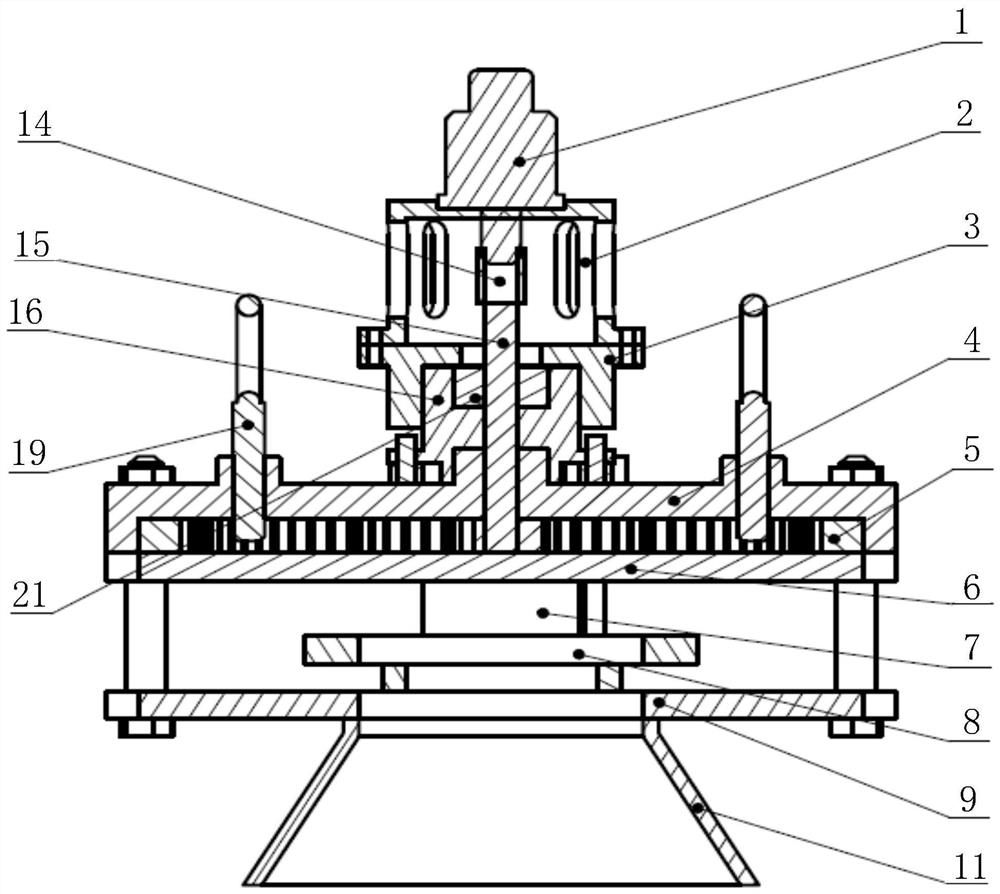

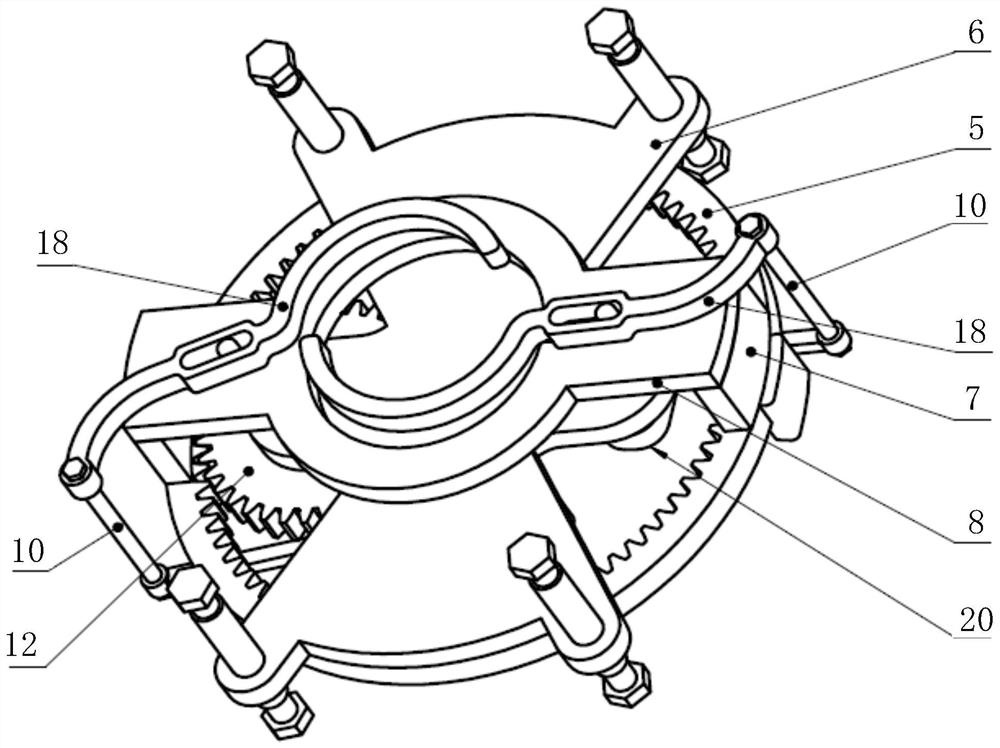

[0041] Such as Figure 1 to Figure 13The shown automatic grasping and lifting device in a reactor includes a stepping motor 1, a support frame 2, a shaft coupling 14 and lifting lugs 19. The stepping motor 1 is installed on the support frame 2, and the coupling 14 Installed on the stepper motor 1 shaft, it also includes a fixed mount 3, an upper fixed plate 4, a middle fixed plate 6, a lower fixed plate 9, a driving frame 16 and a rotating frame 21, and the upper fixed plate 4, the middle fixed plate 6 and the lower fixed plate 9 are stacked and connected in turn by bolts and nuts, and two spaces are formed between the fixed plates through sleeve support, the fixed frame 3 is welded on the upper fixed plate 4, and the drive frame 16 is coaxially installed on the fixed frame 3, it can rotate at a certain angle in the fixed frame 3, the rotating frame is installed on the groove on the drive frame 16, the support frame 2 is installed on the fixed frame 3 through nuts; the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com